A condenser is a crucial component in refrigeration and air conditioning systems that transforms refrigerant vapor into liquid by removing heat. Its efficient heat exchange process enhances system performance and energy savings. Discover how understanding condenser types and maintenance can optimize your system by reading the full article.

Table of Comparison

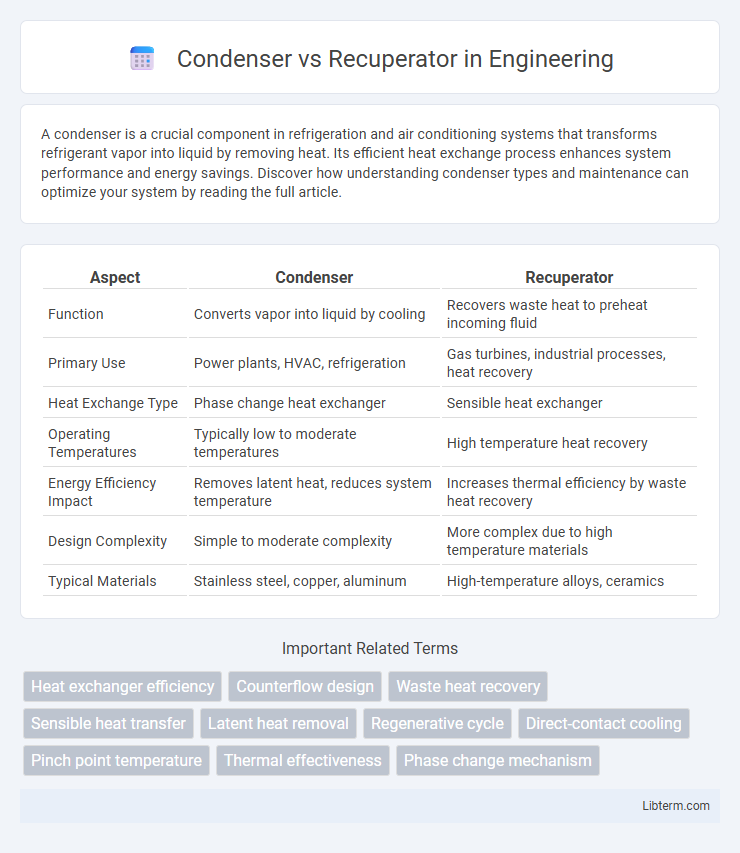

| Aspect | Condenser | Recuperator |

|---|---|---|

| Function | Converts vapor into liquid by cooling | Recovers waste heat to preheat incoming fluid |

| Primary Use | Power plants, HVAC, refrigeration | Gas turbines, industrial processes, heat recovery |

| Heat Exchange Type | Phase change heat exchanger | Sensible heat exchanger |

| Operating Temperatures | Typically low to moderate temperatures | High temperature heat recovery |

| Energy Efficiency Impact | Removes latent heat, reduces system temperature | Increases thermal efficiency by waste heat recovery |

| Design Complexity | Simple to moderate complexity | More complex due to high temperature materials |

| Typical Materials | Stainless steel, copper, aluminum | High-temperature alloys, ceramics |

Introduction to Heat Recovery Systems

Heat recovery systems enhance energy efficiency by capturing and reusing waste heat from industrial processes, significantly reducing operational costs and environmental impact. A condenser transfers heat by condensing vapor into liquid, effectively recovering latent heat, while a recuperator recovers sensible heat by exchanging hot and cold gases without phase change. Selecting between condensers and recuperators depends on process conditions, temperature ranges, and the type of heat exchange required for optimal thermal energy recovery.

What is a Condenser?

A condenser is a heat exchange device that converts vapor into liquid by removing latent heat through cooling surfaces, commonly used in power plants, HVAC systems, and refrigeration cycles. It improves system efficiency by recycling condensing steam or refrigerant, reducing energy losses. Key types include surface condensers, where steam contacts cooled tubes, and direct-contact condensers, allowing direct mixing of vapor and coolant.

What is a Recuperator?

A recuperator is a heat exchanger designed to recover waste heat from exhaust gases and transfer it to the incoming fresh air or fluid, improving energy efficiency in industrial processes. Unlike condensers, which primarily remove latent heat by condensing vapor into liquid, recuperators focus on sensible heat recovery without phase change. Commonly used in gas turbines, furnaces, and HVAC systems, recuperators reduce fuel consumption and lower emissions by preheating combustion air or process fluids.

Working Principles: Condenser vs Recuperator

A condenser operates by transferring heat from a hot vapor to a cooler fluid, causing the vapor to condense into a liquid through latent heat extraction. A recuperator functions by recovering waste heat from hot exhaust gases and transferring it to incoming air or fluid, improving thermal efficiency without phase change. Both devices enhance energy efficiency but differ in their heat exchange mechanisms and applications within thermal systems.

Key Applications and Industries

Condensers are primarily used in power plants, refrigeration, and HVAC systems to convert steam or vapor into liquid, enhancing energy efficiency and system performance. Recuperators find key applications in high-temperature industrial processes such as steel manufacturing, glass production, and gas turbines, where they recover waste heat to preheat combustion air and reduce fuel consumption. Both heat exchangers play critical roles in industries like chemical processing, energy generation, and metallurgy by optimizing thermal energy recovery and lowering operational costs.

Efficiency Comparison: Condenser vs Recuperator

Recuperators typically offer higher efficiency in heat recovery compared to condensers, as they transfer sensible heat from exhaust gases to incoming air without phase change losses. Condensers recover latent heat by condensing steam or vapor, which can significantly improve overall system efficiency in applications involving phase transitions. Efficiency comparisons depend on specific use cases; recuperators excel in continuous gas-to-gas heat exchange, while condensers provide superior performance in systems utilizing condensation for heat recovery.

Advantages of Using a Condenser

A condenser effectively recovers heat by transforming exhaust gases into liquid, significantly enhancing energy efficiency in industrial processes. It reduces pollution by minimizing harmful emissions and conserving water through the cooling and condensation cycle. The compact design and ease of maintenance of condensers make them ideal for applications requiring reliable, continuous operation.

Benefits of Implementing Recuperators

Recuperators enhance energy efficiency by recovering waste heat from exhaust gases to preheat incoming air or fluids, substantially reducing fuel consumption and operational costs. They improve thermal performance in industrial processes, leading to lower greenhouse gas emissions and compliance with environmental regulations. Maintenance requirements are minimal due to their simple design, providing long-term reliability and cost savings compared to traditional condensers.

Cost Considerations and Maintenance

Condenser systems typically have lower upfront costs but require regular maintenance to prevent fouling, which can increase operational expenses over time. Recuperators often involve higher initial investment due to their complex design but provide improved energy efficiency and reduced operational costs in the long term. Maintenance for recuperators is generally less frequent but requires specialized skills to ensure optimal heat recovery performance.

Choosing the Right Solution for Your Process

Selecting the right solution between a condenser and a recuperator depends on the specific heat recovery needs and process conditions. Condensers excel at phase-change heat recovery by condensing vapors to liquids, making them ideal for processes with significant latent heat, while recuperators transfer sensible heat between fluids without phase change, suited for continuous gas streams. Evaluating factors such as temperature ranges, fluid types, energy efficiency goals, and maintenance requirements ensures optimal performance and cost-effectiveness in industrial applications.

Condenser Infographic

libterm.com

libterm.com