Welding is a critical fabrication process that joins materials, primarily metals, using intense heat to create strong, durable bonds. Mastering various welding techniques, such as MIG, TIG, and stick welding, enhances both precision and efficiency in industrial and artistic projects. Discover how you can improve your welding skills and safety by exploring the detailed insights in the rest of this article.

Table of Comparison

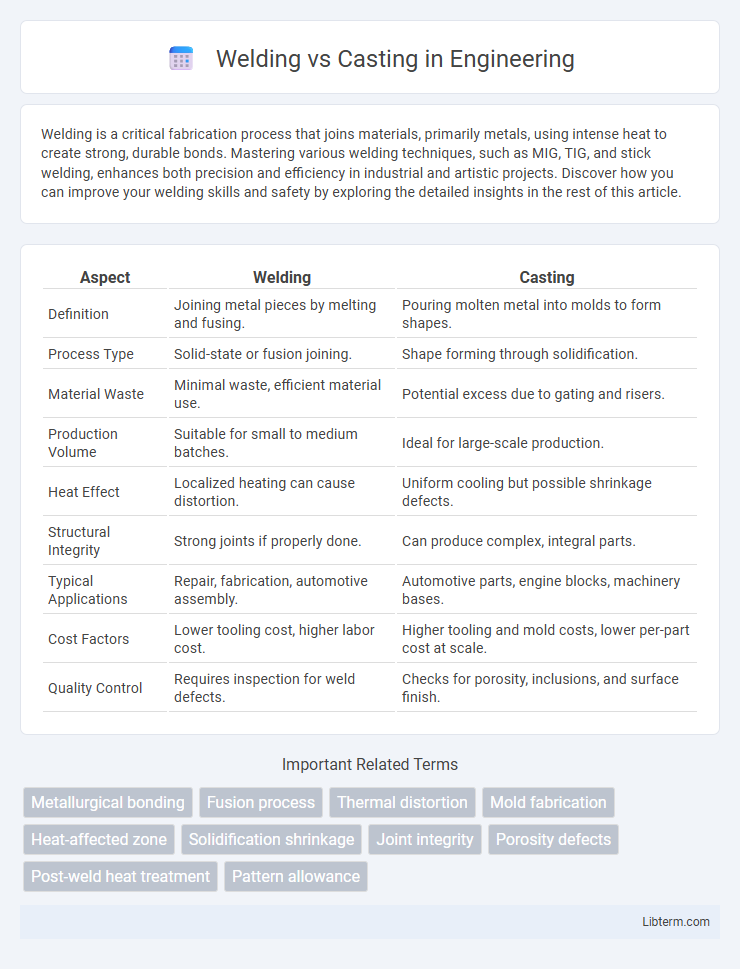

| Aspect | Welding | Casting |

|---|---|---|

| Definition | Joining metal pieces by melting and fusing. | Pouring molten metal into molds to form shapes. |

| Process Type | Solid-state or fusion joining. | Shape forming through solidification. |

| Material Waste | Minimal waste, efficient material use. | Potential excess due to gating and risers. |

| Production Volume | Suitable for small to medium batches. | Ideal for large-scale production. |

| Heat Effect | Localized heating can cause distortion. | Uniform cooling but possible shrinkage defects. |

| Structural Integrity | Strong joints if properly done. | Can produce complex, integral parts. |

| Typical Applications | Repair, fabrication, automotive assembly. | Automotive parts, engine blocks, machinery bases. |

| Cost Factors | Lower tooling cost, higher labor cost. | Higher tooling and mold costs, lower per-part cost at scale. |

| Quality Control | Requires inspection for weld defects. | Checks for porosity, inclusions, and surface finish. |

Introduction to Welding and Casting

Welding joins metals by melting their edges and adding filler material to create a strong, permanent bond, commonly used in construction and manufacturing industries. Casting involves pouring molten metal into a mold, allowing it to solidify into a specific shape, widely utilized for complex geometries and mass production. Both processes are essential in metal fabrication, yet they differ fundamentally in technique and application.

Fundamental Differences Between Welding and Casting

Welding involves joining two or more metal pieces by melting their edges and allowing them to fuse upon cooling, creating a continuous joint, whereas casting consists of pouring molten metal into a mold to solidify into a desired shape. The fundamental difference lies in welding being a fabrication process that joins existing parts, while casting is a manufacturing process that forms new metal components from liquid metal. Welding requires localized heat and filler material, while casting relies on mold design and metal solidification to achieve final dimensions.

Process Overview: How Welding Works

Welding joins metals by applying intense heat to melt and fuse materials at the joint, creating a strong and seamless bond upon cooling. This process uses methods such as arc welding, gas welding, or resistance welding, which involve electric arcs, gas flames, or electrical resistance to generate the necessary heat. Welding is ideal for fabrication and repair as it allows precise control over the weld area and material properties, unlike casting that involves pouring molten metal into molds.

Process Overview: How Casting Works

Casting involves pouring molten metal into a mold where it solidifies into the desired shape, allowing for complex geometries and large components to be produced with uniform properties. The process includes pattern creation, mold preparation, metal melting, pouring, cooling, and removal of the cast part. Unlike welding, which fuses materials by localized heating, casting forms the entire component in a single step, enabling mass production of intricate metal parts.

Material Compatibility for Welding and Casting

Welding requires high material compatibility, typically involving metals with similar melting points and chemical compositions to achieve strong, defect-free joints and prevent issues like cracking or corrosion. Casting tolerates a broader range of alloys since the metal is melted and poured into molds, allowing complex shapes but may introduce material inconsistencies such as porosity or shrinkage defects. Understanding the specific metallurgical properties is essential to select appropriate materials for welding or casting to ensure structural integrity and performance.

Strength and Durability Comparison

Welding typically produces joints with strength nearing or exceeding the base metals, offering high tensile and shear strength essential for structural applications. Casting, while capable of creating complex shapes, may introduce porosity and internal defects that can reduce overall durability and lead to stress concentration points. The choice between welding and casting depends on application-specific requirements, with welded components generally providing superior durability under dynamic or cyclic loads.

Cost Efficiency: Welding vs Casting

Welding offers superior cost efficiency in small-scale or custom projects due to lower initial setup costs and faster production times compared to casting. Casting requires significant investment in mold creation and longer lead times, making it more economical for large-volume manufacturing with consistent part designs. Evaluating project scale and production requirements is critical to determining whether welding or casting delivers the best return on investment.

Applications and Industry Usage

Welding is extensively used in industries like construction, automotive, aerospace, and shipbuilding for joining metal parts with high strength and precision, making it ideal for structural frameworks and repairs. Casting is predominant in manufacturing sectors such as automotive engine production, heavy machinery, and aerospace components where complex shapes, durability, and mass production of metal parts are essential. Both processes play crucial roles, with welding favored for assembly and repair, while casting excels in creating intricate, high-strength components.

Advantages and Disadvantages of Welding and Casting

Welding offers precise joining of metals with high strength and minimal material waste, making it ideal for complex structures and repairs, but it requires skilled labor and can introduce residual stresses or distortions. Casting allows for the production of intricate shapes directly from molten metal, enabling mass production and versatility in material selection, yet it often involves longer cooling times and potential defects like porosity or shrinkage. Both processes have unique advantages in manufacturing, with welding excelling in assembly and repair, while casting is preferred for forming complex geometries and bulk production.

Choosing the Right Method: Factors to Consider

Choosing the right method between welding and casting depends on factors such as material type, mechanical stresses, and design complexity. Welding is ideal for joining metals with high strength and flexibility requirements, while casting suits complex shapes and large-scale production. Cost efficiency, production speed, and desired surface finish should also influence the decision.

Welding Infographic

libterm.com

libterm.com