The Brayton cycle is a thermodynamic process commonly used in jet engines and gas turbines to convert fuel into mechanical energy. It involves four key stages: compression, combustion, expansion, and exhaust, optimizing efficiency through continuous flow. Explore the rest of the article to understand how the Brayton cycle can enhance your energy systems' performance.

Table of Comparison

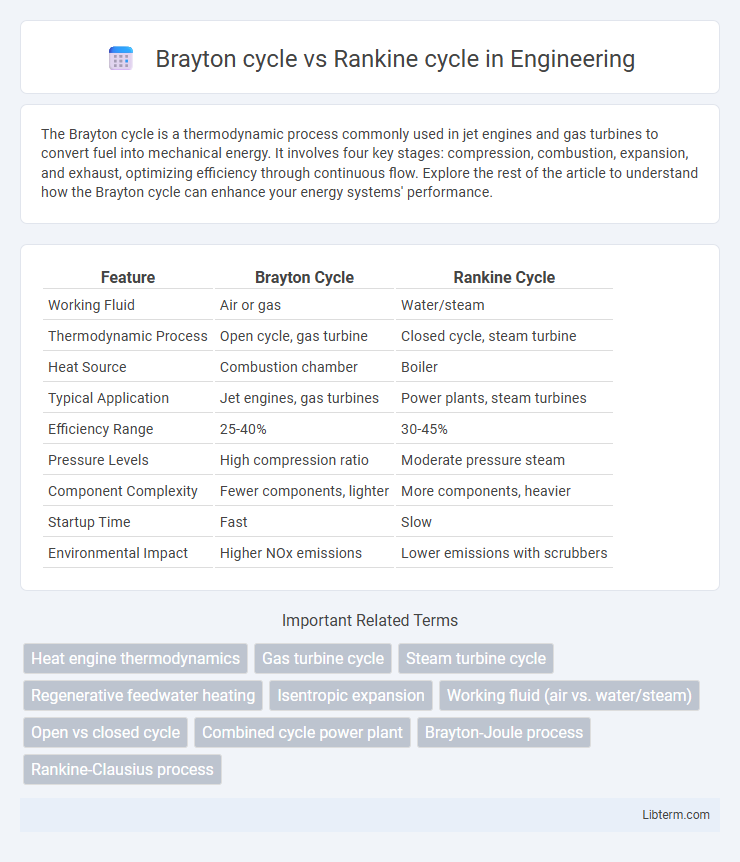

| Feature | Brayton Cycle | Rankine Cycle |

|---|---|---|

| Working Fluid | Air or gas | Water/steam |

| Thermodynamic Process | Open cycle, gas turbine | Closed cycle, steam turbine |

| Heat Source | Combustion chamber | Boiler |

| Typical Application | Jet engines, gas turbines | Power plants, steam turbines |

| Efficiency Range | 25-40% | 30-45% |

| Pressure Levels | High compression ratio | Moderate pressure steam |

| Component Complexity | Fewer components, lighter | More components, heavier |

| Startup Time | Fast | Slow |

| Environmental Impact | Higher NOx emissions | Lower emissions with scrubbers |

Introduction to Brayton and Rankine Cycles

The Brayton cycle operates on a gas turbine principle involving continuous combustion and high-pressure air expansion, primarily used in jet engines and power plants. The Rankine cycle converts heat into mechanical work using phase changes of water or steam, forming the basis of most thermal power stations. Both cycles optimize thermodynamic efficiency through compression, heat addition, expansion, and heat rejection processes.

Fundamental Principles of Brayton Cycle

The Brayton cycle operates on the principle of continuous combustion with air as the working fluid, involving isentropic compression, constant pressure heat addition, isentropic expansion, and constant pressure heat rejection. Key components include a compressor, combustion chamber, and turbine, where the cycle converts fuel energy into mechanical work primarily for gas turbine engines. Efficiency depends on the pressure ratio and turbine inlet temperature, distinguishing it from the Rankine cycle that relies on phase change of working fluid in steam power plants.

Fundamental Principles of Rankine Cycle

The Rankine cycle operates on the principle of phase change of a working fluid, typically water, between liquid and vapor states to convert heat into mechanical work in steam power plants. It involves four main processes: isentropic compression in a pump, constant-pressure heat addition in a boiler, isentropic expansion in a turbine, and constant-pressure heat rejection in a condenser. This thermodynamic cycle is designed to maximize efficiency by exploiting the latent heat of vaporization and is commonly utilized in thermal power generation due to its ability to handle high pressure and high temperature steam.

Key Differences in Working Fluids

The Brayton cycle primarily uses air or other gases as its working fluid, operating in a continuous gaseous phase throughout the cycle. In contrast, the Rankine cycle employs a liquid-vapor phase change, typically using water or steam as the working fluid to convert heat into mechanical work. This fundamental difference influences the thermodynamic properties and efficiency ranges of each cycle, with Brayton suited for gas turbines and Rankine for steam turbines.

Thermodynamic Processes Comparison

The Brayton cycle operates through isentropic compression and expansion combined with constant-pressure heat addition and rejection, primarily in gas turbines, optimizing high-temperature gas flow for power generation. In contrast, the Rankine cycle involves isentropic compression and expansion with constant-pressure heat addition and rejection, utilizing phase changes in a working fluid, typically steam, for efficient thermal to mechanical energy conversion in steam turbines. The key difference lies in the Brayton cycle's gas-phase working fluid and continuous flow process, while the Rankine cycle uses phase change and a closed-loop liquid-vapor system, impacting efficiency and application suitability.

Efficiency Analysis: Brayton vs Rankine

The Brayton cycle, commonly used in gas turbine engines, typically achieves higher thermal efficiencies at higher turbine inlet temperatures due to its constant pressure heat addition process. The Rankine cycle, predominantly applied in steam power plants, demonstrates improved efficiency with superheating and regeneration but generally operates at lower peak temperatures and pressures compared to Brayton cycles. Efficiency analysis reveals that Brayton cycles excel in applications requiring rapid startup and variable loads, while Rankine cycles maintain superior efficiency in large-scale, steady-state power generation scenarios.

Common Applications of Each Cycle

The Brayton cycle is predominantly used in gas turbine engines for aircraft propulsion and power generation in jet turbines, where high efficiency at high temperatures is critical. The Rankine cycle is widely applied in thermal power plants and steam turbines for electricity generation, utilizing phase change of water to maximize energy conversion from heat sources such as coal, nuclear, or solar power. Industrial applications of the Rankine cycle include cogeneration systems and waste heat recovery, while Brayton cycles are favored in aerospace and combined cycle power plants for their rapid start-up and compact design.

Advantages and Disadvantages

The Brayton cycle offers higher thermal efficiency at high temperatures and is commonly used in gas turbines for power generation and aviation due to its quick start-up and compact design. However, it suffers from lower efficiency at lower temperatures and requires expensive materials to withstand high operating pressures. The Rankine cycle is more versatile for varying heat sources and better suited for large-scale power plants using steam turbines, providing reliable operation at lower temperatures but typically has lower overall efficiency and slower startup times compared to the Brayton cycle.

Environmental Impact and Emissions

The Brayton cycle, commonly used in gas turbine power plants, typically emits higher levels of nitrogen oxides (NOx) and carbon dioxide (CO2) due to the combustion of fossil fuels at high temperatures, contributing significantly to air pollution and greenhouse gas effects. In contrast, the Rankine cycle, often employed in steam power plants fueled by coal, natural gas, or nuclear energy, produces varied emissions depending on the energy source, with fossil-fuel Rankine systems releasing substantial sulfur dioxide (SO2), NOx, and CO2, while nuclear Rankine plants have negligible direct emissions but pose long-term environmental risks from radioactive waste. Strategies to mitigate environmental impact include improving combustion efficiency, integrating carbon capture technologies, and increasing the use of renewable or low-carbon fuels in both cycles to minimize atmospheric pollutant and greenhouse gas outputs.

Future Developments and Technological Innovations

Future developments in the Brayton cycle emphasize advanced materials and cooling techniques to boost turbine efficiency and enable higher inlet temperatures, while integration with renewable energy sources like solar thermal power aims to reduce carbon emissions. In Rankine cycle advancements, supercritical and ultra-supercritical steam conditions, along with improvements in heat exchanger design and working fluids, enhance thermal efficiency and flexibility for hybrid power systems. Emerging technologies such as carbon capture integration and organic Rankine cycle applications for waste heat recovery further highlight innovation trends driving sustainable power generation.

Brayton cycle Infographic

libterm.com

libterm.com