Mercury relays offer reliable switching performance through the use of liquid mercury, which ensures low contact resistance and high conductivity. These relays are ideal for applications requiring fast, precise, and long-lasting electrical contacts. Discover how a mercury relay can enhance your system's efficiency by reading the full article.

Table of Comparison

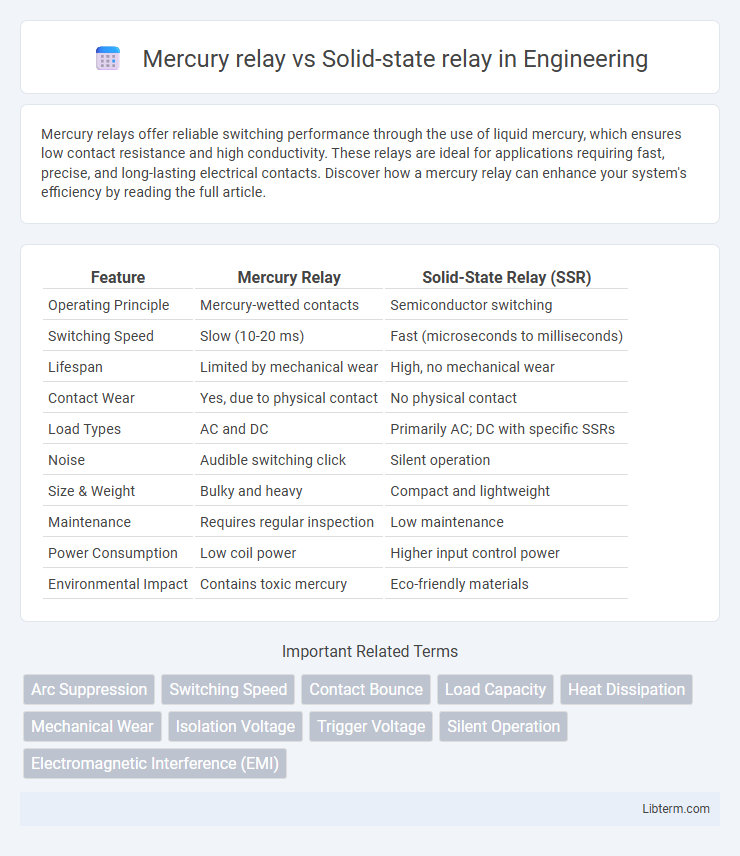

| Feature | Mercury Relay | Solid-State Relay (SSR) |

|---|---|---|

| Operating Principle | Mercury-wetted contacts | Semiconductor switching |

| Switching Speed | Slow (10-20 ms) | Fast (microseconds to milliseconds) |

| Lifespan | Limited by mechanical wear | High, no mechanical wear |

| Contact Wear | Yes, due to physical contact | No physical contact |

| Load Types | AC and DC | Primarily AC; DC with specific SSRs |

| Noise | Audible switching click | Silent operation |

| Size & Weight | Bulky and heavy | Compact and lightweight |

| Maintenance | Requires regular inspection | Low maintenance |

| Power Consumption | Low coil power | Higher input control power |

| Environmental Impact | Contains toxic mercury | Eco-friendly materials |

Introduction to Relays: Mercury vs Solid-State

Mercury relays utilize a pool of mercury to establish electrical connections, providing reliable switching with low contact resistance and high current capacity. Solid-state relays (SSRs) rely on semiconductor components like thyristors or transistors, offering silent operation, faster switching speeds, and longer lifespan due to the absence of mechanical parts. Both relay types are essential in industrial automation, with mercury relays favored for their ruggedness and SSRs preferred for their efficiency and noise-free performance.

Working Principles of Mercury Relays

Mercury relays operate by tilting a sealed glass tube containing liquid mercury to open or close electrical contacts, relying on the movement of the conductive mercury to establish the circuit connection. This mechanical action provides smooth and low-resistance switching, making mercury relays highly reliable for handling moderate currents with minimal contact wear. In contrast, solid-state relays use semiconductor devices like thyristors or triacs to switch electrical loads without moving parts, resulting in faster switching times and greater durability in high-frequency applications.

How Solid-State Relays Function

Solid-state relays (SSRs) function by using semiconductor components such as thyristors, triacs, or transistors to switch electrical loads without moving parts, resulting in silent operation and longer lifespan compared to mechanical mercury relays. SSRs isolate the control circuit from the load using optical coupling, enhancing safety and reducing electromagnetic interference. The absence of physical contacts in SSRs eliminates contact wear and arcing, making them ideal for rapid switching and high-cycle applications.

Key Differences Between Mercury and Solid-State Relays

Mercury relays utilize a mercury-wetted contact which offers low contact resistance and excellent bounce-free switching, making them ideal for precise low-current applications. Solid-state relays (SSRs) employ semiconductor devices such as thyristors or triacs to perform switching with no moving parts, providing faster response times, longer lifespan, and superior resistance to shock and vibration. Key differences include durability, switching speed, electrical noise generation, and suitability for high-frequency or heavy-load applications, with SSRs preferred for silent operation and rapid switching while mercury relays provide reliable mechanical contact in sensitive circuits.

Advantages of Mercury Relays

Mercury relays offer superior electrical contact reliability and exceptionally low contact resistance, ensuring stable and consistent performance in critical switching applications. Their hermetically sealed design provides excellent resistance to environmental contaminants, resulting in longer operational lifespan and reduced maintenance requirements compared to solid-state relays. Mercury relays also handle high inrush currents better, making them ideal for use in high-load and industrial environments.

Benefits of Solid-State Relays

Solid-state relays (SSRs) offer significant benefits over mercury relays, including faster switching speeds and longer operational lifespans due to the absence of mechanical moving parts. SSRs provide enhanced reliability and resistance to shock and vibration, making them ideal for industrial applications requiring high durability. Their low power consumption and silent operation further contribute to energy efficiency and noise reduction in automated systems.

Application Areas: Where Each Relay Excels

Mercury relays excel in high-frequency switching applications and precise signal control, commonly used in telecommunications, instrumentation, and aerospace systems due to their low contact resistance and long operational life. Solid-state relays are ideal for industrial automation, heating control, and motor drives, where fast switching, noise immunity, and vibration resistance are critical. Each relay type is selected based on specific operational demands, with mercury relays favored for sensitive, low-current circuits and solid-state relays preferred for high-speed, high-power environments.

Reliability and Lifespan Comparison

Mercury relays exhibit exceptional reliability with minimal contact degradation due to their liquid metal contacts, resulting in lifespans often exceeding several million operations under optimal conditions. Solid-state relays (SSRs) offer high reliability with no moving parts, eliminating mechanical wear and enabling lifespans typically rated in the hundreds of thousands to millions of switching cycles, depending on heat dissipation and operating conditions. While mercury relays can outperform traditional electromechanical relays in terms of contact life, SSRs provide enhanced durability in harsh environments due to their resistance to vibration and shock, making both choices highly dependable but suited to different application demands.

Safety, Environmental, and Regulatory Considerations

Mercury relays contain toxic mercury, posing significant environmental hazards and requiring strict regulatory compliance for disposal and handling under hazardous waste laws. Solid-state relays (SSRs) offer enhanced safety by eliminating mercury, reducing risk of leakage and exposure, and adhering more easily to RoHS and WEEE directives for electronic equipment. SSRs also provide longer service life and greater reliability, minimizing maintenance-related environmental impacts and aligning with modern safety standards.

Choosing the Right Relay for Your Application

Mercury relays offer high reliability and long mechanical life, making them ideal for applications requiring low contact resistance and precise switching in sensitive instruments. Solid-state relays (SSRs) provide fast switching speeds, silent operation, and better resistance to shock and vibration, suited for high-frequency or automated industrial environments. Select mercury relays for low current, low noise requirements, while SSRs excel in high-speed, high-durability scenarios with minimal maintenance needs.

Mercury relay Infographic

libterm.com

libterm.com