Surface rolling enhances material properties by inducing plastic deformation, which improves fatigue resistance and surface finish. This process reduces surface roughness and compressive stresses, extending the lifespan of metal components. Discover how surface rolling can optimize your manufacturing outcomes in the rest of this article.

Table of Comparison

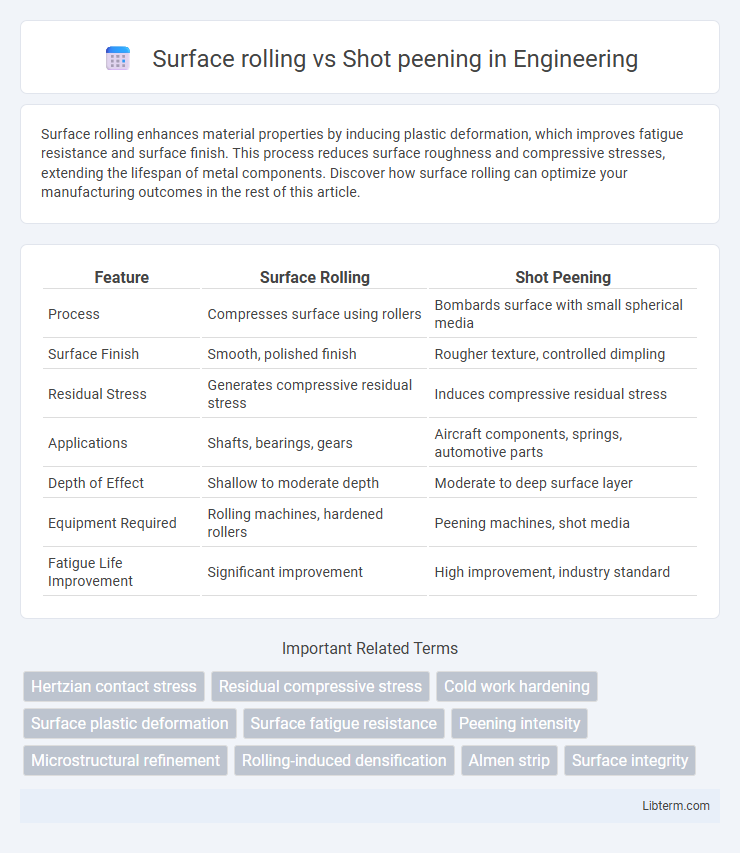

| Feature | Surface Rolling | Shot Peening |

|---|---|---|

| Process | Compresses surface using rollers | Bombards surface with small spherical media |

| Surface Finish | Smooth, polished finish | Rougher texture, controlled dimpling |

| Residual Stress | Generates compressive residual stress | Induces compressive residual stress |

| Applications | Shafts, bearings, gears | Aircraft components, springs, automotive parts |

| Depth of Effect | Shallow to moderate depth | Moderate to deep surface layer |

| Equipment Required | Rolling machines, hardened rollers | Peening machines, shot media |

| Fatigue Life Improvement | Significant improvement | High improvement, industry standard |

Introduction to Surface Rolling and Shot Peening

Surface rolling is a mechanical process that enhances the surface finish and mechanical properties of metal components through controlled plastic deformation, which improves fatigue strength and wear resistance. Shot peening involves bombarding a metal surface with small spherical media, inducing compressive residual stresses that increase resistance to fatigue and stress corrosion cracking. Both techniques are essential in surface engineering for extending component lifespan in aerospace, automotive, and manufacturing industries.

Core Principles of Surface Rolling

Surface rolling involves plastic deformation of a metal surface using rollers to induce compressive residual stress and improve fatigue resistance, enhancing the material's mechanical properties. It refines surface roughness and strain-hardens the outer layer without creating micro-cracks, in contrast to shot peening, which utilizes high-velocity impact by small spheres to achieve peening effects. The core principle of surface rolling lies in controlled indentation depth and uniform application of pressure to produce consistent surface enhancement and stress profiles.

How Shot Peening Works

Shot peening works by propelling small spherical media, called shots, at high velocity onto the metal surface, creating a layer of compressive residual stress that enhances fatigue strength and resistance to stress corrosion cracking. Unlike surface rolling, which plastically deforms the surface through mechanical pressure, shot peening induces microscopic indentations that prevent crack initiation and propagation. This process is widely used in aerospace, automotive, and manufacturing industries to extend the lifespan of critical components such as gears, springs, and turbine blades.

Comparative Surface Treatments: Goals and Outcomes

Surface rolling enhances fatigue strength by plastically deforming the surface to produce compressive residual stresses and improve surface finish, while shot peening induces compressive stresses through controlled impact by small spherical media to increase hardness and resistance to crack initiation. Both treatments aim to improve fatigue life and wear resistance but differ in application methods and the uniformity of stress distribution, with shot peening providing more consistent coverage on complex geometries. Optimal selection between surface rolling and shot peening depends on factors such as material type, component geometry, and desired surface characteristics for specific engineering applications.

Microstructural Changes: Surface Rolling vs Shot Peening

Surface rolling induces microstructural changes by producing a highly uniform, dense layer with compressive residual stresses that enhance fatigue strength and hardness through plastic deformation and grain refinement. Shot peening generates a more heterogeneous microstructure with localized plastic deformation and introduces compressive residual stresses via controlled impact of metallic or ceramic shots, promoting improved crack resistance and surface durability. Both techniques refine surface grains and modify residual stress profiles, but surface rolling provides a smoother finish and more consistent depth of microstructural alteration compared to the rougher, randomly impacted surface created by shot peening.

Effects on Fatigue Life and Durability

Surface rolling induces beneficial compressive residual stresses and smoothes surface irregularities, significantly enhancing fatigue life by reducing crack initiation sites. Shot peening also introduces compressive stresses but with a more uniform coverage, improving resistance to stress corrosion and fatigue crack growth. Both techniques extend durability, with surface rolling favoring improved surface finish and shot peening offering superior hardness and toughness in treated components.

Equipment and Process Requirements

Surface rolling utilizes large rollers or cylindrical tools to plastically deform the metal surface, requiring precise control of pressure and feed rate to ensure uniform compressive stresses. Shot peening involves blasting the surface with small spherical media at high velocities, demanding specialized air or mechanical blasting equipment with adjustable intensity and coverage parameters. Both processes need rigorous calibration and monitoring to optimize residual stress profiles for fatigue resistance enhancement.

Cost-Efficiency Analysis

Surface rolling generally offers higher cost-efficiency than shot peening due to lower operational expenses and faster processing times, especially in large-scale manufacturing environments. Shot peening requires specialized equipment and consumables such as abrasive media, increasing maintenance and material costs. However, shot peening provides superior fatigue resistance and surface hardness, which may justify higher upfront costs in high-stress applications.

Industry Applications and Use Cases

Surface rolling enhances fatigue strength and improves surface finish in automotive and aerospace components by inducing compressive residual stress and reducing surface roughness. Shot peening is widely used in heavy machinery, power generation, and marine industries to increase resistance to stress corrosion cracking and extend the lifespan of metal parts through controlled plastic deformation. Both techniques optimize durability and performance, with surface rolling favored for precision parts and shot peening applied more extensively in large-scale, high-stress environments.

Choosing the Best Method for Metal Surface Enhancement

Surface rolling enhances metal surfaces by applying controlled plastic deformation to improve hardness and fatigue resistance, making it ideal for cylindrical parts. Shot peening uses high-velocity spherical media to induce compressive residual stresses that prevent crack initiation, particularly effective for complex geometries and aerospace components. Selecting the best method depends on part geometry, desired surface properties, and cost-efficiency, with surface rolling preferred for simple shapes and shot peening favored for intricate or highly stressed components.

Surface rolling Infographic

libterm.com

libterm.com