Torsional moment refers to the twisting force applied to an object, causing it to rotate around its axis. This mechanical concept is crucial in engineering and physics for analyzing the strength and stability of shafts, beams, and other structural elements under torsional stress. Explore the rest of the article to understand how torsional moment affects various materials and design applications.

Table of Comparison

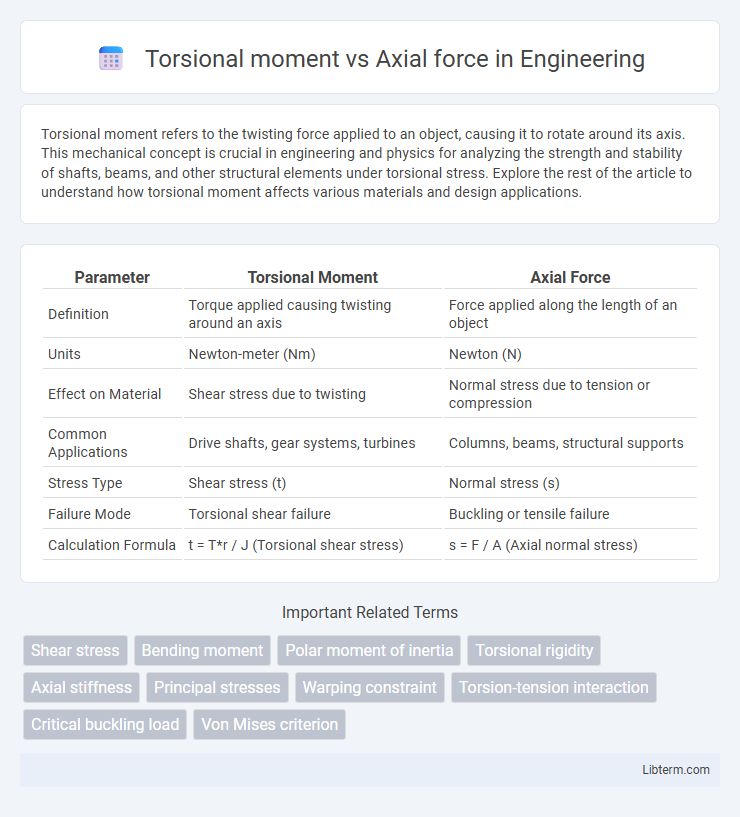

| Parameter | Torsional Moment | Axial Force |

|---|---|---|

| Definition | Torque applied causing twisting around an axis | Force applied along the length of an object |

| Units | Newton-meter (Nm) | Newton (N) |

| Effect on Material | Shear stress due to twisting | Normal stress due to tension or compression |

| Common Applications | Drive shafts, gear systems, turbines | Columns, beams, structural supports |

| Stress Type | Shear stress (t) | Normal stress (s) |

| Failure Mode | Torsional shear failure | Buckling or tensile failure |

| Calculation Formula | t = T*r / J (Torsional shear stress) | s = F / A (Axial normal stress) |

Introduction to Torsional Moment and Axial Force

Torsional moment refers to the twisting effect produced by a torque applied to a structural member, causing shear stress and angular deformation around its longitudinal axis. Axial force is a linear force acting along the length of a structural element, resulting in either tension or compression, and influencing normal stress distribution. Understanding the interaction between torsional moment and axial force is critical in structural engineering to ensure stability and prevent failure under combined loading conditions.

Fundamental Definitions and Concepts

Torsional moment, also known as torque, is the measure of the twisting force applied to an object causing rotational motion around its axis, quantified in Newton-meters (Nm). Axial force refers to the linear force applied along the axis of a structural member, resulting in either tension or compression, measured in Newtons (N). Understanding the interplay between torsional moment and axial force is crucial for analyzing stress distribution and deformation in engineering components subjected to combined loading conditions.

Physical Differences Between Torsion and Axial Loading

Torsional moment involves twisting an object around its longitudinal axis, generating shear stress that varies radially within the material. Axial force acts along the length of the object, producing normal stress uniformly distributed across the cross-section. The primary physical difference lies in the type of stress induced: torsion causes shear stress, while axial loading results in tensile or compressive normal stress.

Mathematical Representation of Torsional Moments

Torsional moments are mathematically represented by the equation \( T = GJ \frac{d\theta}{dx} \), where \(T\) is the torsional moment, \(G\) is the modulus of rigidity, \(J\) is the polar moment of inertia, and \(\frac{d\theta}{dx}\) is the rate of twist along the shaft length. Axial force typically acts along the longitudinal axis and is expressed as \( F = \sigma A \), where \(F\) is the axial force, \(\sigma\) is the normal stress, and \(A\) is the cross-sectional area. The torsional moment induces shear stresses, whereas axial force results in normal stresses, defining distinct mechanical effects in structural analysis.

Mathematical Analysis of Axial Forces

Mathematical analysis of axial forces involves quantifying the internal stresses and strains resulting from tension or compression along a structural member's longitudinal axis. Axial force \( F \) creates normal stress calculated as \( \sigma = \frac{F}{A} \), where \( A \) is the cross-sectional area, influencing deformation and overall stability. Understanding this relationship enables precise evaluation of structural components subjected to combined torsional moments and axial loads for optimized design and safety.

Effects of Torsional Moment on Structural Elements

Torsional moment induces shear stresses that can compromise the structural integrity of beams, shafts, and columns, often leading to warping or distortion in elements with open cross-sections. The interaction between torsional moments and axial forces intensifies stress concentrations, increasing the risk of buckling or fatigue failure in slender structural components. Engineers must account for these combined loads to ensure the safety and durability of critical infrastructure such as bridges, towers, and mechanical shafts.

Impact of Axial Force on Structural Performance

Axial force significantly influences torsional moment capacity by affecting the stress distribution in structural members, often increasing the potential for buckling under combined loading conditions. Higher axial loads typically reduce the structural element's ability to resist torsion, as compressive forces exacerbate lateral-torsional buckling and distortional instability. Engineers must account for these interactions to ensure accurate assessment of load-bearing capacity and prevent premature failure in columns, beams, and shafts.

Key Applications in Engineering and Design

Torsional moment and axial force are critical factors in the structural analysis of shafts, beams, and fasteners, directly influencing their performance under combined loading conditions. Key applications include the design of drive shafts in automotive engineering, where torsional moments cause twisting while axial forces manage compressive or tensile stresses. Understanding their interaction optimizes material selection and cross-sectional geometry, enhancing durability and preventing failure in mechanical and civil engineering structures.

Failure Modes: Torsion vs Axial Loading

Torsional moment induces shear stresses that primarily lead to twisting failure modes such as shaft yielding or torsional fatigue, whereas axial force generates normal stresses causing failure through buckling or axial fracture. Materials under torsional loading commonly experience shear failure along planes at 45 degrees to the axis, contrasted with axial loading that typically results in tensile or compressive failure parallel to the load direction. Understanding the distinct stress distributions and deformation patterns is crucial for designing components exposed to combined torsion and axial forces to prevent catastrophic failure.

Comparative Summary and Practical Implications

Torsional moment and axial force represent distinct mechanical loads that influence structural performance differently; torsional moments cause twisting around an axis, while axial forces induce compression or tension along the length of a member. Comparative analysis reveals that materials subjected to torsional stresses require higher shear strength, whereas axial loads primarily demand tensile or compressive strength, impacting design choices and safety factors. In practical applications, accurate assessment of both loads is critical for ensuring structural integrity in components such as shafts, beams, and columns, optimizing material usage and preventing failure modes like buckling or torsional fatigue.

Torsional moment Infographic

libterm.com

libterm.com