Magnetic bearings use magnetic fields to support rotating shafts without physical contact, reducing friction and wear while enhancing performance in high-speed applications. They offer benefits like increased efficiency, lower maintenance, and improved operational lifespan compared to traditional bearings. Discover how magnetic bearings can transform your machinery by reading the rest of the article.

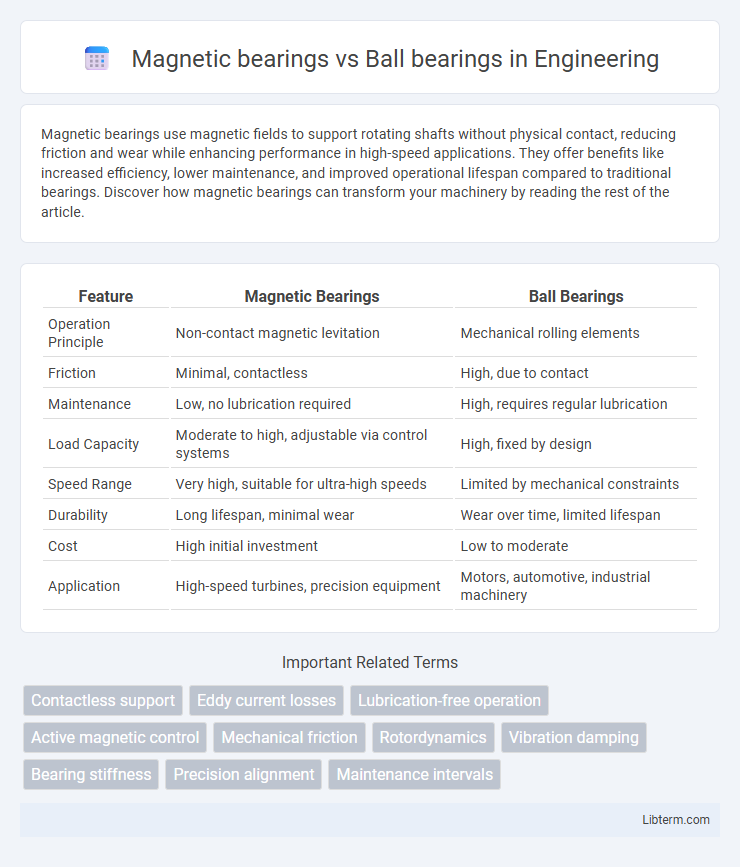

Table of Comparison

| Feature | Magnetic Bearings | Ball Bearings |

|---|---|---|

| Operation Principle | Non-contact magnetic levitation | Mechanical rolling elements |

| Friction | Minimal, contactless | High, due to contact |

| Maintenance | Low, no lubrication required | High, requires regular lubrication |

| Load Capacity | Moderate to high, adjustable via control systems | High, fixed by design |

| Speed Range | Very high, suitable for ultra-high speeds | Limited by mechanical constraints |

| Durability | Long lifespan, minimal wear | Wear over time, limited lifespan |

| Cost | High initial investment | Low to moderate |

| Application | High-speed turbines, precision equipment | Motors, automotive, industrial machinery |

Introduction to Magnetic Bearings and Ball Bearings

Magnetic bearings use magnetic fields to levitate and support rotating shafts without physical contact, significantly reducing friction and wear compared to traditional ball bearings, which rely on rolling elements housed within races to support loads. Magnetic bearings offer high-speed operation, low maintenance, and improved efficiency, making them ideal for applications requiring precision and cleanliness such as turbines and vacuum environments. Ball bearings, widely used across various industries, provide reliable mechanical support and load distribution at lower costs but suffer from mechanical wear and require lubrication.

How Magnetic Bearings Work

Magnetic bearings use electromagnetic fields to levitate and support rotating shafts without physical contact, reducing friction and wear significantly compared to traditional ball bearings. These systems rely on sensors and control electronics to continuously adjust the magnetic forces, maintaining precise shaft positioning even at high speeds. This contactless operation enhances efficiency, minimizes maintenance, and enables quieter, vibration-free performance in applications like turbines and advanced machinery.

How Ball Bearings Work

Ball bearings function by using small steel balls positioned between two smooth, hardened rings called races, which allow the bearing to support radial and axial loads while minimizing friction. As the shaft rotates, the balls roll smoothly, reducing contact area and enabling efficient motion with lower energy loss compared to sliding friction. This mechanical design offers reliable performance, durability, and cost-effectiveness in various industrial and automotive applications.

Key Differences Between Magnetic and Ball Bearings

Magnetic bearings use magnetic fields to levitate and support rotating shafts without physical contact, offering virtually frictionless operation and reduced wear, while ball bearings rely on rolling elements to minimize friction but involve mechanical contact. Magnetic bearings provide higher precision, lower maintenance, and the ability to operate in extreme environments such as vacuum or high-speed applications, unlike ball bearings which may suffer from lubrication issues and wear under harsh conditions. The key differences lie in their operating principles, lifespan, and suitability for high-speed or contamination-sensitive uses, making magnetic bearings ideal for advanced aerospace, turbo machinery, and semiconductor equipment.

Efficiency and Performance Comparison

Magnetic bearings offer superior efficiency due to their near-frictionless operation, resulting in reduced energy consumption and minimal wear compared to traditional ball bearings. Their ability to maintain stable rotor support at high speeds enhances performance, providing smoother operation and longer service life in demanding applications. Ball bearings, while cost-effective and reliable for moderate speeds, experience higher friction and mechanical wear, leading to reduced efficiency and more frequent maintenance.

Maintenance and Longevity

Magnetic bearings offer superior longevity and reduced maintenance compared to ball bearings due to their contactless operation, which eliminates wear and friction. Ball bearings require regular lubrication and periodic replacement because mechanical contact causes gradual degradation of components. The absence of physical contact in magnetic bearings significantly extends service life and decreases downtime in industrial applications.

Applications in Industry

Magnetic bearings excel in high-speed industrial applications such as turbines, compressors, and flywheels due to their frictionless, non-contact operation, resulting in reduced wear and maintenance. Ball bearings are widely used in conveyors, motors, and automotive components where cost-effectiveness and load capacity are critical. Industries prioritize magnetic bearings in environments requiring clean, lubrication-free operation and enhanced reliability, while ball bearings dominate in traditional mechanical systems demanding robustness and affordability.

Cost Considerations

Magnetic bearings typically involve higher initial costs due to advanced technology and complex control systems, while ball bearings are more cost-effective with lower upfront expenses. Maintenance costs for magnetic bearings are generally lower since they lack physical contact and wear, whereas ball bearings require regular replacements and lubrication. Over the long term, magnetic bearings may prove more economical in high-performance or precision applications despite the expensive setup.

Environmental Impact and Sustainability

Magnetic bearings generate no friction or wear, eliminating the need for lubricants and reducing environmental contamination compared to ball bearings, which rely on grease and oil that can pollute ecosystems. The longer lifespan and reduced maintenance of magnetic bearings lead to lower material consumption and waste production. Ball bearings' manufacturing and disposal processes contribute more significantly to resource depletion and landfill waste, making magnetic bearings a more sustainable option for environmentally conscious industries.

Choosing the Right Bearing for Your Needs

Magnetic bearings offer frictionless operation, reduced maintenance, and high-speed capability, making them ideal for precision applications like turbines and medical devices, whereas ball bearings provide cost-effective reliability suited for everyday machinery and moderate-speed requirements. Selecting the right bearing depends on factors such as load capacity, rotational speed, operational environment, and maintenance preferences. For applications demanding longevity and minimal wear, magnetic bearings excel, while ball bearings remain practical for versatile, lower-cost solutions.

Magnetic bearings Infographic

libterm.com

libterm.com