Drag is a force that opposes the motion of an object through a fluid, such as air or water, impacting speed and energy efficiency. Understanding drag is crucial for optimizing designs in vehicles, aircraft, and sports equipment to enhance performance. Explore the article to discover how reducing drag can improve your speed and efficiency.

Table of Comparison

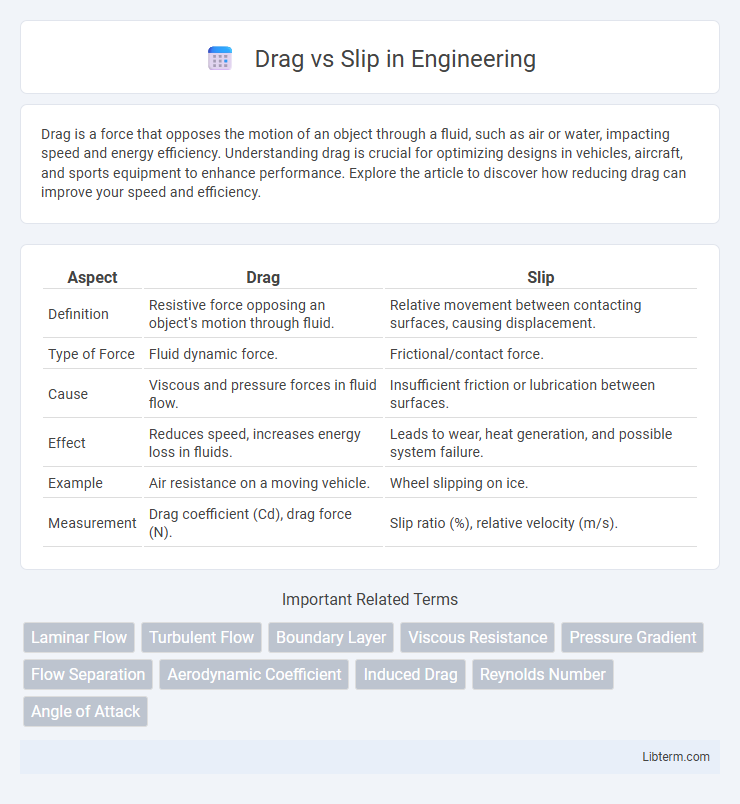

| Aspect | Drag | Slip |

|---|---|---|

| Definition | Resistive force opposing an object's motion through fluid. | Relative movement between contacting surfaces, causing displacement. |

| Type of Force | Fluid dynamic force. | Frictional/contact force. |

| Cause | Viscous and pressure forces in fluid flow. | Insufficient friction or lubrication between surfaces. |

| Effect | Reduces speed, increases energy loss in fluids. | Leads to wear, heat generation, and possible system failure. |

| Example | Air resistance on a moving vehicle. | Wheel slipping on ice. |

| Measurement | Drag coefficient (Cd), drag force (N). | Slip ratio (%), relative velocity (m/s). |

Understanding Drag and Slip: Key Concepts

Drag refers to the resistive force acting opposite to the motion of an object through a fluid, influenced by factors such as shape, surface roughness, and fluid velocity. Slip occurs when there is relative movement between a fluid layer and a solid surface, characterized by a non-zero velocity at the interface, which challenges the classical no-slip boundary condition typically assumed in fluid dynamics. Understanding the interplay between drag and slip is crucial for optimizing fluid flow in applications like microfluidics and aerodynamic design, where controlling boundary behavior significantly impacts efficiency and performance.

The Physics Behind Drag

Drag is a resistive force that opposes an object's motion through a fluid, caused by the interaction between the object's surface and fluid particles. It arises from two primary components: pressure drag, resulting from the shape and flow separation, and skin friction drag, generated by viscous shear stresses in the boundary layer. Understanding the physics behind drag involves analyzing fluid dynamics principles, such as the Reynolds number, flow velocity, and the object's surface roughness.

What is Slip in Engineering Terms?

Slip in engineering terms refers to the relative motion between two contacting surfaces, typically when one surface moves over another without full adherence, causing a difference in velocity at the interface. It commonly occurs in mechanical systems such as gears, bearings, and conveyor belts, where the driving and driven components do not rotate or move at exactly the same speed. Understanding slip is essential for analyzing frictional losses, wear, and efficiency in machines.

Factors Affecting Drag and Slip

Drag and slip are influenced by key factors such as surface roughness, fluid viscosity, and velocity gradients at the boundary layer. Increased surface roughness enhances drag by creating turbulent flow, while slip length depends on molecular interactions at the interface, modulated by fluid properties and temperature. Understanding these variables enables optimization of fluid dynamics in engineering applications, reducing energy losses and improving system efficiency.

Drag vs Slip: Core Differences

Drag refers to the resistive force acting opposite to the relative motion of an object moving through a fluid, while slip describes the relative tangential motion between a fluid and a solid surface. Drag quantifies energy loss and is influenced by factors such as shape, surface roughness, and fluid viscosity, whereas slip indicates partial fluid movement at the boundary condition, often characterized by slip length or slip velocity. The core difference lies in drag representing a force opposing motion, while slip defines the boundary interaction allowing non-zero fluid velocity at the solid interface.

Real-World Applications of Drag

Drag affects fuel efficiency in automotive design by increasing air resistance, leading to higher energy consumption. In aerospace engineering, minimizing drag is crucial for improving aircraft speed and reducing operational costs. Sports equipment, such as cycling helmets and swimsuits, utilize drag reduction technologies to enhance performance and endurance.

The Role of Slip in Mechanical Systems

Slip in mechanical systems significantly influences energy efficiency and wear resistance by allowing controlled relative motion between contacting surfaces, reducing frictional forces and heat generation. Unlike drag, which represents resistive forces opposing motion, slip facilitates smoother operation in components such as bearings, clutches, and conveyor belts by preventing excessive force buildup and mechanical stress. Optimizing slip parameters enhances system durability and performance, especially in applications involving rotational and translational movements.

Minimizing Drag and Slip: Techniques and Strategies

Minimizing drag and slip involves optimizing surface textures, streamlining shapes, and employing advanced materials such as hydrophobic coatings to reduce friction and fluid resistance. Techniques like boundary layer control through suction or blowing and precise alignment of components help maintain laminar flow, decreasing drag forces significantly. Employing computational fluid dynamics (CFD) simulations allows engineers to design aerodynamic or hydrodynamic forms that effectively balance slip reduction with performance efficiency.

Measuring Drag and Slip: Tools and Methods

Measuring drag and slip involves specialized tools such as drag gauges, flow meters, and slip sensors to quantify resistance and slippage in fluids and mechanical systems. Techniques include using anemometers to assess drag force in aerodynamic testing and rotary encoders paired with slip rings to detect relative motion or slippage in rotating machinery. Advanced methods leverage laser Doppler velocimetry and torque transducers to achieve precise and real-time measurements critical for optimizing performance and reducing energy losses.

Impact of Drag and Slip on Performance and Efficiency

Drag increases resistance against motion, directly reducing speed and fuel efficiency in vehicles, aircraft, and marine vessels. Slip, defined as the relative motion between surfaces in contact, causes energy loss through friction and heat, lowering mechanical efficiency in engines and brakes. Minimizing both drag and slip is crucial for optimizing performance, as reduced drag conserves energy while controlled slip ensures effective power transmission and improved system reliability.

Drag Infographic

libterm.com

libterm.com