A boiler efficiently heats water or produces steam for heating and industrial processes, ensuring consistent warmth and energy savings. Modern boilers offer advanced controls and safety features that optimize performance and reduce fuel consumption. Discover how upgrading Your boiler system can improve efficiency and comfort by reading the rest of this article.

Table of Comparison

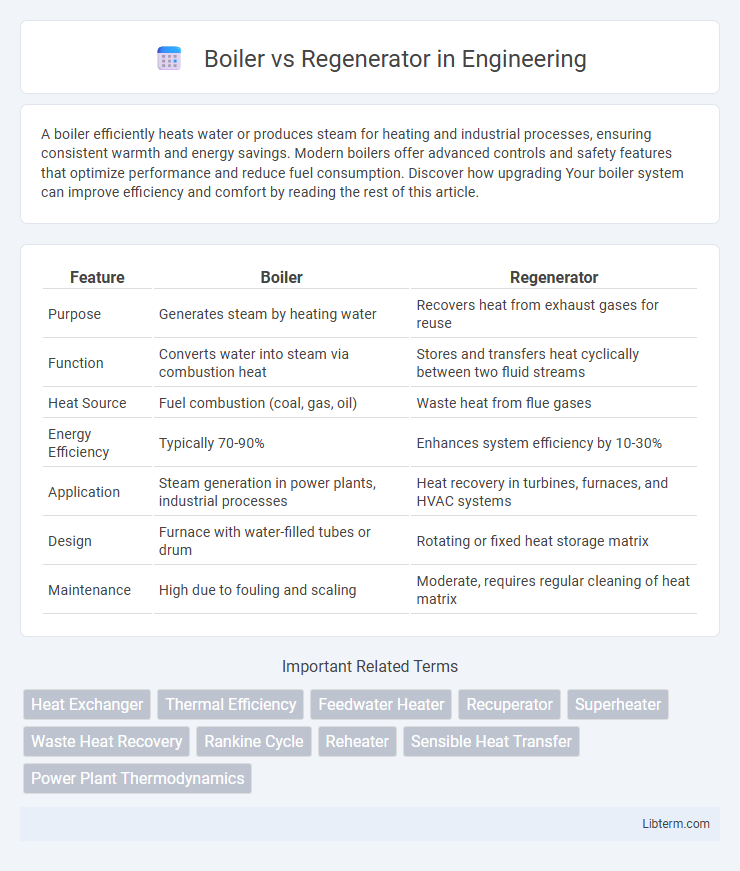

| Feature | Boiler | Regenerator |

|---|---|---|

| Purpose | Generates steam by heating water | Recovers heat from exhaust gases for reuse |

| Function | Converts water into steam via combustion heat | Stores and transfers heat cyclically between two fluid streams |

| Heat Source | Fuel combustion (coal, gas, oil) | Waste heat from flue gases |

| Energy Efficiency | Typically 70-90% | Enhances system efficiency by 10-30% |

| Application | Steam generation in power plants, industrial processes | Heat recovery in turbines, furnaces, and HVAC systems |

| Design | Furnace with water-filled tubes or drum | Rotating or fixed heat storage matrix |

| Maintenance | High due to fouling and scaling | Moderate, requires regular cleaning of heat matrix |

Introduction: Boiler vs Regenerator

Boilers and regenerators serve distinct roles in thermal systems, with boilers converting water into steam through direct heat application, while regenerators recover waste heat from flue gases to preheat incoming air or fluids. Boilers are essential in power plants and industrial processes for steam generation, whereas regenerators enhance energy efficiency by recycling heat within the system. Understanding their operational differences is crucial for optimizing thermal energy management and reducing fuel consumption.

Key Definitions: What is a Boiler?

A boiler is a mechanical device designed to generate steam by heating water through fuel combustion or electric heating elements, commonly used in industrial processes, power generation, and heating systems. It operates by transferring heat energy to water, converting it into steam at high pressure that can drive turbines or heat spaces. Boilers are essential components in energy systems where controlled steam production is required for mechanical work or thermal applications.

Key Definitions: What is a Regenerator?

A regenerator is a heat exchange device designed to recover and reuse thermal energy from hot gases or fluids by temporarily storing heat in a thermal storage medium before transferring it to a cooler fluid stream. It differs from a boiler, which generates steam or hot water by directly heating water through fuel combustion or electrical energy. Regenerators enhance energy efficiency in industrial processes by reducing fuel consumption and lowering emissions through effective heat recovery.

Working Principles: Boiler Explained

A boiler operates by heating water to generate steam through the combustion of fuel, using heat transfer surfaces such as tubes or drums to carry the thermal energy. The steam produced is then utilized for various industrial processes or heating applications. The working principle centers on converting chemical energy into thermal energy and subsequently into mechanical or heat energy via steam.

Working Principles: Regenerator Explained

A regenerator operates by capturing heat from hot exhaust gases and storing it in a thermal storage medium, which is then used to preheat incoming air or gas, increasing energy efficiency. Unlike boilers that generate steam by direct heat from fuel combustion, regenerators recycle waste heat through alternating flow cycles between hot and cold streams. This thermal energy exchange significantly reduces fuel consumption and enhances overall system performance in industrial processes.

Comparative Efficiency: Boiler vs Regenerator

Boilers typically convert fuel energy into steam with efficiencies ranging from 70% to 90%, depending on design and fuel type, while regenerators recover waste heat from exhaust gases, increasing overall system efficiency by up to 20%. The regenerator's ability to recycle thermal energy reduces fuel consumption and operational costs, making it more efficient in continuous high-temperature processes than standard boilers. Efficiency enhancements in regenerators result from their cyclic heat storage and transfer capabilities, which minimize energy losses compared to the direct combustion process in boilers.

Applications and Use Cases

Boilers are widely used in power plants, industrial manufacturing, and heating applications to generate steam or hot water for energy production and process heating. Regenerators are primarily employed in high-temperature industrial processes such as glass manufacturing, steel production, and gas turbines, where waste heat recovery improves thermal efficiency. Both technologies optimize energy use, but boilers focus on steam generation while regenerators enhance heat exchange in cyclic operations.

Energy Consumption and Cost Analysis

Boilers typically consume more energy due to continuous fuel combustion required to generate steam, resulting in higher operational costs compared to regenerators, which recover waste heat to preheat combustion air and improve thermal efficiency. Regenerators can reduce fuel consumption by up to 30%, significantly lowering energy expenses and reducing greenhouse gas emissions. While initial investment costs for regenerators may be higher, their long-term cost savings and energy efficiency gains make them more economical in large-scale industrial applications.

Maintenance and Operational Considerations

Boiler maintenance requires regular inspection of pressure vessels, heat exchangers, and safety valves to prevent leaks and ensure efficient combustion, with frequent monitoring of water chemistry to avoid scaling and corrosion. Regenerators demand consistent cleaning of heat transfer surfaces and periodic replacement of packing materials to maintain optimal heat recovery performance and prevent fouling. Operational considerations for boilers include managing combustion air supply and fuel quality, while regenerators require precise control of flow reversal cycles and temperature differentials for effective energy conservation.

Conclusion: Choosing Between Boiler and Regenerator

Selecting between a boiler and a regenerator depends on the specific industrial process and energy efficiency requirements. Boilers excel in continuous steam generation by directly heating water, making them ideal for industries needing constant steam output. Regenerators are more suited for applications requiring heat recovery and improved thermal efficiency by capturing waste heat from exhaust gases.

Boiler Infographic

libterm.com

libterm.com