Conventional concrete remains the most widely used construction material due to its durability, affordability, and ease of use. It is composed of a mix of cement, water, and aggregates that form a strong and versatile building solution for various projects. Explore the rest of the article to understand the properties, advantages, and applications of conventional concrete in your construction endeavors.

Table of Comparison

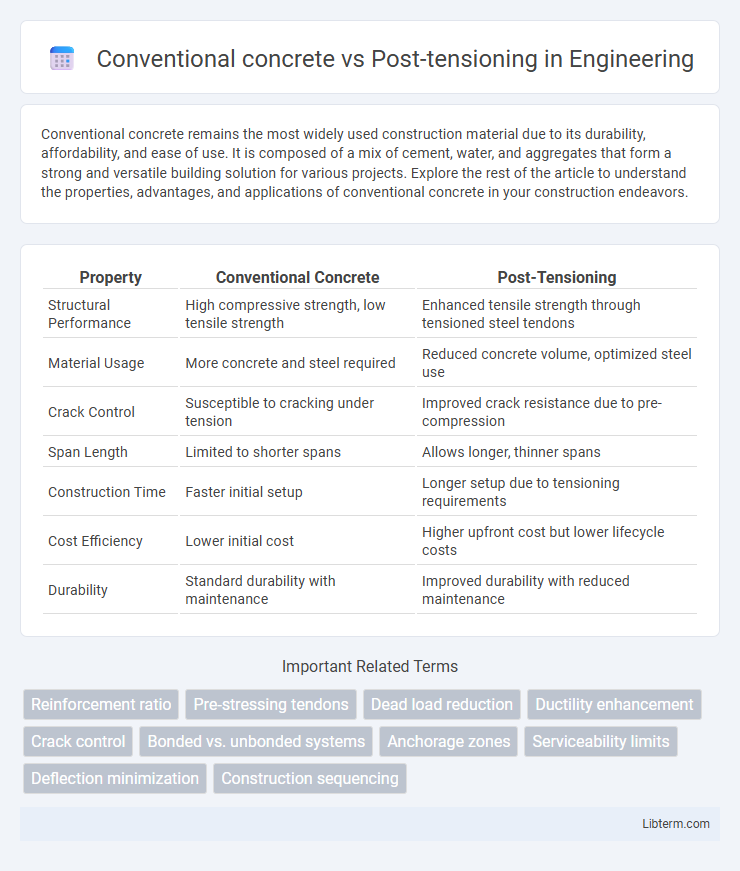

| Property | Conventional Concrete | Post-Tensioning |

|---|---|---|

| Structural Performance | High compressive strength, low tensile strength | Enhanced tensile strength through tensioned steel tendons |

| Material Usage | More concrete and steel required | Reduced concrete volume, optimized steel use |

| Crack Control | Susceptible to cracking under tension | Improved crack resistance due to pre-compression |

| Span Length | Limited to shorter spans | Allows longer, thinner spans |

| Construction Time | Faster initial setup | Longer setup due to tensioning requirements |

| Cost Efficiency | Lower initial cost | Higher upfront cost but lower lifecycle costs |

| Durability | Standard durability with maintenance | Improved durability with reduced maintenance |

Overview of Conventional Concrete and Post-Tensioning

Conventional concrete relies on steel reinforcement bars embedded within the concrete to resist tensile forces, providing structural strength primarily through the concrete's compressive capacity combined with rebar's tensile strength. Post-tensioning enhances this system by introducing tendons, typically high-strength steel cables, that are tensioned after the concrete has cured, actively compressing the concrete to improve load-bearing capabilities and reduce crack development. This method allows for longer spans, thinner slabs, and greater design flexibility compared to traditional reinforced concrete.

Historical Development and Adoption

Conventional concrete dates back to ancient civilizations such as the Romans, who pioneered its use with a simple mixture of cement, water, and aggregates, becoming widespread during the 19th century Industrial Revolution for building durable structures. Post-tensioning emerged in the mid-20th century as an innovative technique to enhance concrete performance by applying tension to steel tendons within concrete cast in place, improving load capacity and controlling cracks. The adoption of post-tensioning accelerated globally in commercial and infrastructure projects due to its efficiency in reducing material usage and increasing design flexibility compared to traditional reinforced concrete.

Core Principles and Mechanisms

Conventional concrete relies on steel reinforcement bars embedded within the concrete matrix to resist tensile stresses, relying primarily on the compressive strength of concrete while the rebar handles tension. Post-tensioning involves the application of high-strength steel tendons that are tensioned after the concrete hardens, inducing compressive stress to counteract tensile forces and reduce cracking. This method enhances structural capacity, allows longer spans, and reduces concrete volume compared to conventional reinforced concrete.

Material Requirements and Composition

Conventional concrete primarily relies on ordinary Portland cement, coarse aggregates, fine aggregates, and water, forming a dense, rigid matrix that withstands compressive loads but requires substantial steel reinforcement to handle tensile stresses. Post-tensioning concrete uses high-strength steel tendons embedded within ducts, allowing the concrete to be cast with lower initial reinforcement and less concrete volume, optimizing material usage and enhancing tensile capacity. This method reduces the quantity of reinforcing steel and concrete compaction needed, ultimately improving structural efficiency and durability.

Structural Performance and Load-Bearing Capacity

Conventional concrete relies on passive reinforcement embedded within the mix, which limits its tensile strength and increases susceptibility to cracking under load. Post-tensioning enhances structural performance by applying tension to steel tendons after concrete curing, significantly increasing load-bearing capacity and reducing deflection. This technique optimizes material usage, resulting in thinner slabs and longer spans without compromising durability or strength.

Construction Methods and Installation Processes

Conventional concrete construction involves pouring and curing reinforced concrete with steel rebar, requiring formwork and longer curing times to achieve design strength. Post-tensioning uses high-strength steel tendons tensioned after concrete curing, allowing thinner slabs and longer spans while reducing material usage. Installation of post-tensioned systems demands precise tendon placement, tensioning equipment, and skilled labor to ensure structural integrity and load distribution.

Cost Efficiency and Economic Considerations

Post-tensioning concrete reduces overall material costs by using high-strength steel tendons to allow thinner slabs and longer spans, cutting down on concrete volume and formwork expenses compared to conventional concrete. This method minimizes labor costs and construction time through faster installation and reduced curing periods, enhancing project cash flow and reducing financial carrying costs. Despite higher initial tendon and stressing equipment expenses, post-tensioning's lifecycle savings in maintenance, repair, and structural performance offer superior economic efficiency over traditional cast-in-place concrete methods.

Durability, Maintenance, and Lifespan

Conventional concrete exhibits lower durability under tensile stress, often resulting in cracks that require frequent maintenance to prevent structural damage, thereby shortening its lifespan. Post-tensioning enhances concrete durability by applying compressive forces that reduce tensile stresses, minimizing crack formation and significantly extending the service life of structures. Maintenance demands for post-tensioned concrete are lower due to improved structural integrity, which contributes to longer intervals between repairs and a superior overall lifespan compared to conventional concrete.

Applications in Modern Construction

Conventional concrete is widely used in residential and low-rise commercial buildings due to its simplicity and cost-effectiveness, while post-tensioning is favored in high-rise structures, long-span bridges, and parking garages for its enhanced strength and reduced material usage. Post-tensioning allows for thinner slabs and longer spans without excessive reinforcement, enabling more flexible architectural designs and faster construction. Modern construction increasingly adopts post-tensioned concrete in infrastructure projects to improve load-bearing capacity and durability under dynamic loads.

Environmental Impact and Sustainability

Conventional concrete construction generates higher carbon emissions due to the increased use of cement, a major source of CO2, whereas post-tensioning reduces material volume by enhancing structural efficiency, leading to lower environmental impact. Post-tensioned structures require less concrete and steel, minimizing resource extraction and waste while promoting sustainable building practices. Employing post-tensioning techniques supports green construction goals by improving durability and extending the lifespan of infrastructure, thereby reducing the need for frequent repairs and replacements.

Conventional concrete Infographic

libterm.com

libterm.com