A pressure gauge is an essential instrument used to measure the pressure of gases or liquids in various industrial and mechanical systems, ensuring safety and optimal performance. Accurate pressure readings help prevent equipment failure and maintain process efficiency. Discover how to choose the right pressure gauge for your needs in the rest of the article.

Table of Comparison

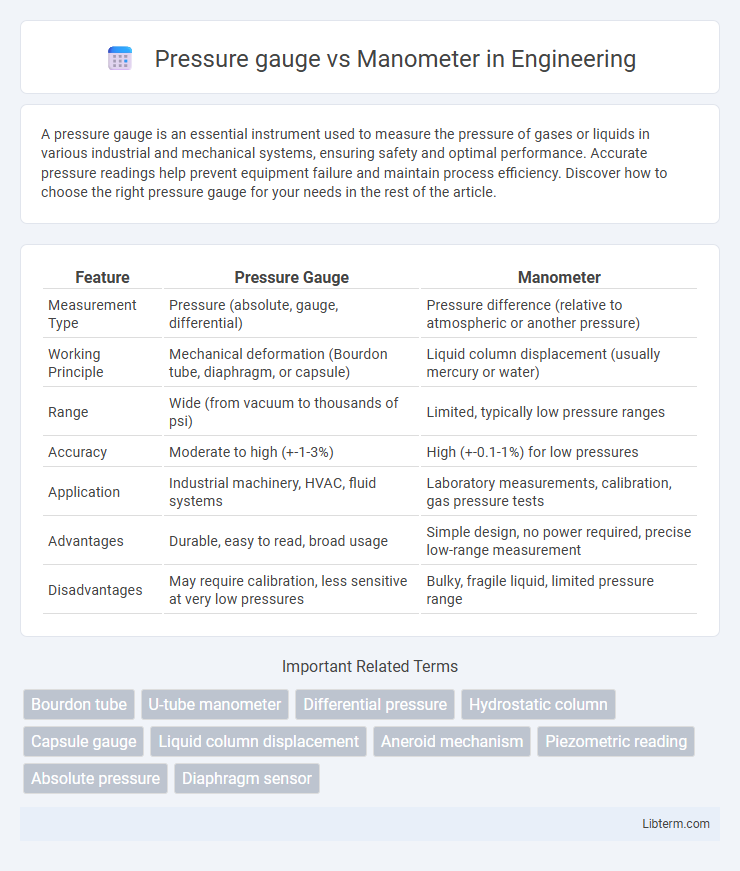

| Feature | Pressure Gauge | Manometer |

|---|---|---|

| Measurement Type | Pressure (absolute, gauge, differential) | Pressure difference (relative to atmospheric or another pressure) |

| Working Principle | Mechanical deformation (Bourdon tube, diaphragm, or capsule) | Liquid column displacement (usually mercury or water) |

| Range | Wide (from vacuum to thousands of psi) | Limited, typically low pressure ranges |

| Accuracy | Moderate to high (+-1-3%) | High (+-0.1-1%) for low pressures |

| Application | Industrial machinery, HVAC, fluid systems | Laboratory measurements, calibration, gas pressure tests |

| Advantages | Durable, easy to read, broad usage | Simple design, no power required, precise low-range measurement |

| Disadvantages | May require calibration, less sensitive at very low pressures | Bulky, fragile liquid, limited pressure range |

Introduction to Pressure Gauges and Manometers

Pressure gauges and manometers are essential devices used for measuring pressure in various industrial and laboratory applications. Pressure gauges provide direct readings of pressure levels using mechanical, digital, or electronic sensors, while manometers measure pressure based on the displacement of a liquid column, typically mercury or water. Understanding their operating principles and accuracy levels is crucial for selecting the appropriate instrument for tasks such as fluid dynamics analysis, HVAC system monitoring, and hydraulic system maintenance.

Understanding Pressure Measurement Principles

Pressure gauges and manometers both measure fluid pressure but operate on different principles and applications. Pressure gauges typically use mechanical elements such as Bourdon tubes or diaphragms to convert pressure into a readable dial, while manometers measure pressure based on the height difference of a fluid column in a U-shaped tube. Understanding these measurement principles is essential for selecting the right instrument for accurate pressure monitoring in industrial, HVAC, or laboratory settings.

Key Differences Between Pressure Gauges and Manometers

Pressure gauges measure pressure directly by converting mechanical force into a readable dial or digital output, often using Bourdon tubes or strain gauges for industrial and HVAC applications. Manometers determine pressure by comparing the height difference of a liquid column, typically mercury or water, making them highly precise for low-pressure measurements and calibration purposes. Unlike manometers, pressure gauges are more versatile for dynamic and high-pressure environments, while manometers excel in static pressure comparison with minimal electrical components.

Types of Pressure Gauges Explained

Pressure gauges include bourdon tube, diaphragm, and digital types, each designed for specific applications and pressure ranges. Bourdon tube gauges are widely used for high-pressure measurement due to their durability and accuracy. Manometers, such as U-tube and inclined manometers, rely on liquid columns to measure pressure differences, making them ideal for low-pressure and differential pressure readings.

Common Variants of Manometers

U-tube, inclined, and digital manometers represent the most common variants used for precise pressure measurements in various applications. U-tube manometers rely on liquid columns to measure pressure differences, offering simplicity and high accuracy for low-pressure ranges. Inclined manometers enhance sensitivity for small pressure variations, while digital manometers provide quick readings and greater versatility across industrial and laboratory settings.

Accuracy and Sensitivity Comparison

Pressure gauges typically offer robust accuracy for a wide range of pressures, with mechanical types providing precision up to +-1% of full scale, while digital versions can achieve even finer resolutions. Manometers, especially U-tube types, excel in sensitivity to small pressure changes due to their direct fluid displacement measurement, making them ideal for low-pressure applications with high accuracy requirements. The sensitivity of manometers often surpasses that of standard pressure gauges, but their practical accuracy depends on fluid properties and environmental conditions, whereas pressure gauges maintain consistent accuracy across varied settings.

Applications of Pressure Gauges in Industry

Pressure gauges are widely used in industries such as oil and gas, manufacturing, and HVAC systems to monitor and control fluid pressure, ensuring equipment safety and process efficiency. They provide real-time pressure readings essential for maintaining optimal operating conditions in pipelines, boilers, and hydraulic systems. Unlike manometers, pressure gauges are preferred for their robustness, ease of use, and suitability in high-pressure and industrial environments.

Use Cases and Benefits of Manometers

Manometers excel in applications requiring precise measurement of low-pressure differentials, such as HVAC systems, laboratory experiments, and gas flow monitoring, where their simplicity and accuracy provide key advantages. Their fluid-based design offers high sensitivity for detecting small pressure changes, making them ideal for calibrating other instruments and ensuring system safety. Compared to pressure gauges, manometers offer benefits like minimal maintenance, no need for power sources, and resistance to electromagnetic interference.

Maintenance and Calibration Requirements

Pressure gauges require regular calibration using standard reference instruments to ensure accurate readings and prevent drift over time, with maintenance involving inspection for leaks, corrosion, and mechanical wear. Manometers, typically simpler devices with liquid columns, demand less frequent calibration but need periodic cleaning and fluid level checks to maintain precision and avoid contamination. Both instruments benefit from scheduled maintenance routines tailored to their specific operational environments to enhance reliability and longevity.

Choosing the Right Device: Pressure Gauge vs. Manometer

Selecting between a pressure gauge and a manometer depends on the measurement accuracy, application environment, and fluid type. Pressure gauges provide direct, durable readings suitable for high-pressure systems, while manometers excel in low-pressure or differential pressure measurements with high precision. Evaluating factors such as pressure range, response time, and installation requirements ensures the right device enhances system performance and safety.

Pressure gauge Infographic

libterm.com

libterm.com