Precast slabs offer superior quality and durability due to factory-controlled production, ensuring uniform strength and reduced construction time. These slabs provide excellent structural integrity, thermal insulation, and soundproofing, making them ideal for various building applications. Discover how precast slabs can enhance Your next construction project by reading the full article.

Table of Comparison

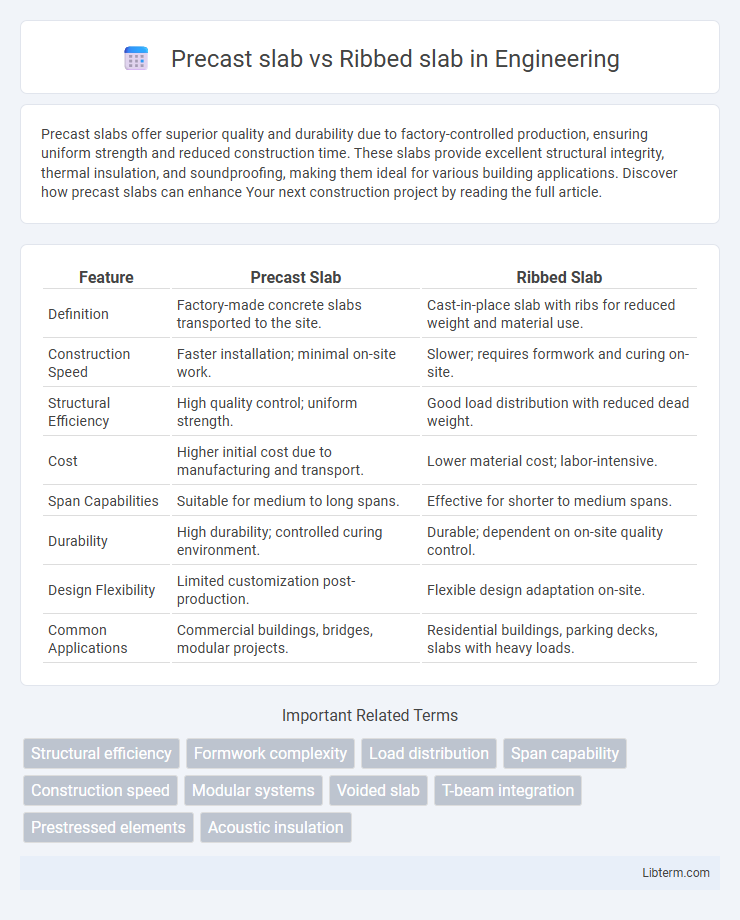

| Feature | Precast Slab | Ribbed Slab |

|---|---|---|

| Definition | Factory-made concrete slabs transported to the site. | Cast-in-place slab with ribs for reduced weight and material use. |

| Construction Speed | Faster installation; minimal on-site work. | Slower; requires formwork and curing on-site. |

| Structural Efficiency | High quality control; uniform strength. | Good load distribution with reduced dead weight. |

| Cost | Higher initial cost due to manufacturing and transport. | Lower material cost; labor-intensive. |

| Span Capabilities | Suitable for medium to long spans. | Effective for shorter to medium spans. |

| Durability | High durability; controlled curing environment. | Durable; dependent on on-site quality control. |

| Design Flexibility | Limited customization post-production. | Flexible design adaptation on-site. |

| Common Applications | Commercial buildings, bridges, modular projects. | Residential buildings, parking decks, slabs with heavy loads. |

Introduction to Precast Slab and Ribbed Slab

Precast slabs are factory-made concrete components designed for quick installation, offering uniform quality, reduced construction time, and enhanced structural strength. Ribbed slabs feature a series of parallel ribs with a thin slab between, optimizing material use and reducing weight while maintaining load-bearing capacity. Both slab types improve construction efficiency but differ in fabrication, installation methods, and structural behavior.

Overview of Precast Slab Systems

Precast slab systems consist of factory-manufactured concrete panels that ensure uniform quality and rapid onsite installation, enhancing construction speed and reducing labor costs. These slabs offer high load-bearing capacity and excellent durability, making them ideal for residential, commercial, and industrial buildings. Compared to ribbed slabs, precast slabs provide better dimensional precision and minimize curing time, which contribute to overall structural efficiency.

Overview of Ribbed Slab Systems

Ribbed slab systems consist of a series of reinforced concrete ribs spaced at regular intervals, supporting a thin concrete topping slab, optimizing material usage and reducing overall weight compared to solid slabs. These slabs enhance load-bearing efficiency and provide better resistance to bending and deflection, making them ideal for large spans in commercial and industrial buildings. Ribbed slabs also facilitate easier installation of mechanical and electrical services due to their voided sections between ribs.

Material Composition and Construction Methods

Precast slabs are typically made from high-strength concrete cast in controlled factory environments, ensuring uniformity and quality, while ribbed slabs consist of a cast-in-situ reinforced concrete beam and slab system with hollow or solid ribs to reduce weight. The construction method for precast slabs involves transporting prefabricated panels to the site for quick installation, minimizing on-site labor and curing time. Ribbed slabs require forming ribs and pouring concrete on-site, offering greater flexibility in design but with longer construction time and increased material usage.

Structural Performance Comparison

Precast slabs offer uniform quality and faster installation with high load-bearing capacity due to factory-controlled manufacturing, while ribbed slabs provide enhanced structural efficiency through reduced self-weight and improved moment distribution with their hollow rib design. Ribbed slabs exhibit superior stiffness-to-weight ratios, reducing overall material usage without compromising structural strength, making them ideal for longer spans. In contrast, precast slabs ensure consistent strength and durability, benefiting projects requiring rapid assembly and minimal on-site labor.

Speed and Efficiency of Installation

Precast slabs offer significantly faster installation speeds due to their factory-made precision and minimal on-site adjustments, reducing overall construction time. Ribbed slabs, while structurally efficient and lightweight, generally require more complex formwork and longer curing periods, slowing down the installation process. Choosing precast slabs enhances project efficiency by streamlining labor demands and ensuring consistent quality with rapid assembly.

Cost Analysis: Precast vs Ribbed Slab

Precast slabs typically offer lower labor costs due to factory-controlled production and faster onsite installation compared to ribbed slabs, which require more formwork and on-site reinforcement. Material costs for ribbed slabs can be higher because of increased concrete volume and steel usage in the ribs, whereas precast slabs benefit from optimized material usage through standardized manufacturing processes. Overall, precast slabs often provide better cost efficiency in large-scale projects due to reduced construction time and minimized site labor expenses.

Design Flexibility and Architectural Implications

Precast slabs offer high design flexibility by allowing precise factory-controlled dimensions and finishes, enabling faster construction with customizable architectural elements. Ribbed slabs provide enhanced structural efficiency with reduced material usage, supporting longer spans and open floor plans that accommodate diverse interior layouts. Both systems influence architectural outcomes significantly, where precast slabs ensure consistent quality and ribbed slabs promote innovative, lightweight designs.

Durability and Maintenance Considerations

Precast slabs offer superior durability due to factory-controlled manufacturing processes that ensure consistent quality and reduced exposure to environmental factors, resulting in lower maintenance requirements over time. Ribbed slabs, while providing efficient material usage and structural strength, may require more frequent inspections and maintenance to address potential issues such as cracking or water infiltration in the ribs. The enhanced durability of precast slabs translates into longer service life and reduced repair costs compared to ribbed slab systems.

Choosing the Right Slab System for Your Project

Precast slabs offer faster installation and consistent quality due to factory manufacturing, making them ideal for projects with tight schedules and repetitive design requirements. Ribbed slabs provide superior load distribution and reduced weight by incorporating hollow ribs, suitable for long-span structures and areas requiring enhanced structural efficiency. Selecting the right slab system depends on factors such as project timeline, structural load demands, budget, and site conditions.

Precast slab Infographic

libterm.com

libterm.com