Single-plane balancing corrects imbalances in rotating components by distributing weight evenly around a single axis, minimizing vibration and enhancing operational efficiency. Proper balancing reduces wear on bearings and extends machinery lifespan, ensuring smoother performance in various industrial applications. Discover how effective single-plane balancing can improve your equipment and prevent costly downtime by exploring the full article.

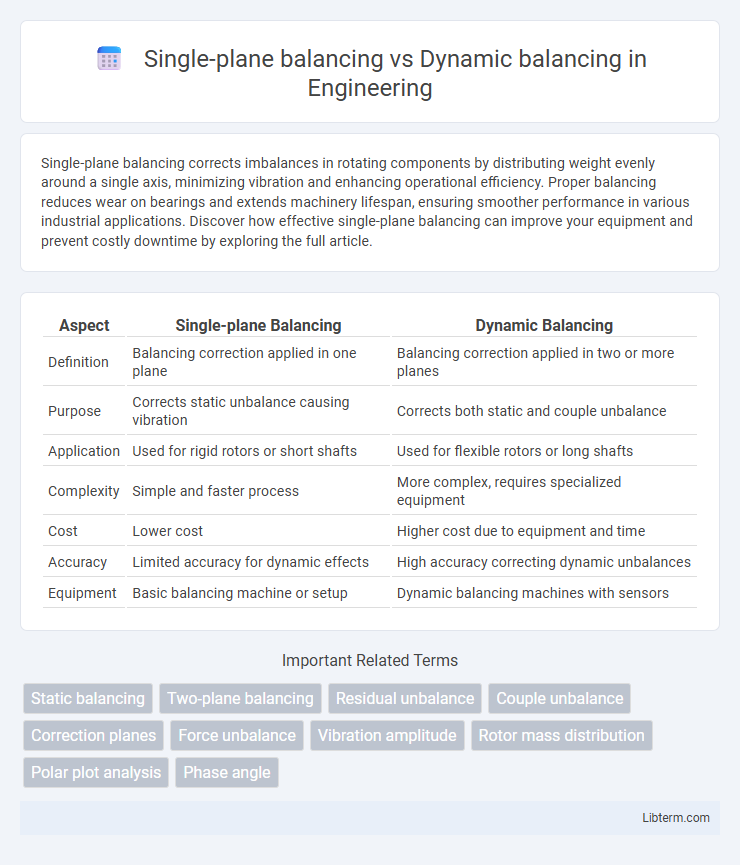

Table of Comparison

| Aspect | Single-plane Balancing | Dynamic Balancing |

|---|---|---|

| Definition | Balancing correction applied in one plane | Balancing correction applied in two or more planes |

| Purpose | Corrects static unbalance causing vibration | Corrects both static and couple unbalance |

| Application | Used for rigid rotors or short shafts | Used for flexible rotors or long shafts |

| Complexity | Simple and faster process | More complex, requires specialized equipment |

| Cost | Lower cost | Higher cost due to equipment and time |

| Accuracy | Limited accuracy for dynamic effects | High accuracy correcting dynamic unbalances |

| Equipment | Basic balancing machine or setup | Dynamic balancing machines with sensors |

Introduction to Balancing Techniques

Single-plane balancing corrects unbalance by adjusting weights on a single plane, suitable for short and rigid rotors with mass concentrated near the center. Dynamic balancing addresses unbalance in rotors with mass distribution over multiple planes, detecting both static and couple unbalance by measuring vibration in two or more planes. Both techniques improve rotor performance and reduce vibrations, but dynamic balancing provides a more comprehensive solution for high-speed and flexible rotors.

What is Single-Plane Balancing?

Single-plane balancing is a method used to correct unbalance in rotating objects by adding or removing weight from a single plane along the rotor's axis. This technique focuses on eliminating the primary imbalance that causes vibration, typically in simpler or shorter rotors where unbalance occurs mainly in one plane. Single-plane balancing is more cost-effective and faster but less precise than dynamic balancing, which addresses imbalances across multiple planes for complex or longer rotors.

What is Dynamic Balancing?

Dynamic balancing refers to the process of balancing a rotating object by correcting both the static and couple unbalance that occur when the object's mass is unevenly distributed along its axis of rotation. Unlike single-plane balancing, which only addresses unbalance in one plane, dynamic balancing involves measuring and correcting unbalances in two planes, ensuring smoother operation at higher speeds. This method reduces vibration and increases the lifespan of rotating machinery in automotive, aerospace, and industrial applications.

Key Differences Between Single-Plane and Dynamic Balancing

Single-plane balancing focuses on correcting unbalance in a single rotational plane, making it ideal for objects with uniform mass distribution like fans or disks, whereas dynamic balancing addresses unbalance across multiple planes, essential for long or flexible rotors such as crankshafts or turbine blades. Single-plane balancing measures and corrects static unbalance, preventing vibration due to mass offset in one plane, while dynamic balancing detects both static and couple unbalances that cause vibration during rotation at high speeds. The key difference lies in the complexity and application: single-plane balancing suits simpler, rigid rotors, while dynamic balancing is crucial for extended shafts requiring precision in multiple planes to ensure operational stability and reduce mechanical wear.

Applications of Single-Plane Balancing

Single-plane balancing is primarily used for rotors with mass concentrated in a single plane, such as fans, propellers, and small electric motor rotors, where correcting imbalance in one plane is sufficient for smooth operation. This balancing technique reduces vibration, extends component life, and improves performance in applications with low-speed or rigid rotors. Unlike dynamic balancing, single-plane balancing is cost-effective and simpler, making it ideal for maintenance tasks in automotive wheels, pumps, and small machinery.

Applications of Dynamic Balancing

Dynamic balancing is essential for rotating machinery with multiple planes of rotation such as crankshafts, turbines, and automotive wheels, where vibrations from unbalanced mass affect performance and lifespan. This method measures and corrects imbalances in two or more planes, ensuring smoother operation and reduced wear at high speeds. Unlike single-plane balancing, dynamic balancing is critical in aerospace, industrial fans, and precision equipment to maintain stability and prevent structural damage during operation.

Advantages of Single-Plane Balancing

Single-plane balancing offers a simpler and more cost-effective solution for correcting unbalance in components with a single plane of rotation, making it ideal for lightweight or thin rotors such as fans and small pulleys. It requires less complex equipment and shorter setup times compared to dynamic balancing, allowing quicker maintenance and reduced downtime. This method effectively addresses imbalance in applications where axial forces are negligible, enhancing operational efficiency and prolonging bearing life.

Advantages of Dynamic Balancing

Dynamic balancing provides superior vibration reduction by addressing imbalances in multiple planes, enhancing the operational lifespan of rotating machinery compared to single-plane balancing. This method improves machine stability and efficiency, leading to smoother performance and reduced wear on components. Additionally, dynamic balancing minimizes noise and prevents damage caused by complex rotor imbalances, making it essential for high-speed applications.

Limitations and Challenges of Each Method

Single-plane balancing is limited by its inability to correct complex vibration issues caused by multiple unbalanced forces acting on different planes, making it suitable mostly for simple, low-speed rotating components. Dynamic balancing addresses these multi-plane imbalances by measuring forces at two or more planes, but it requires more sophisticated equipment, increased time, and higher costs, which can be challenging for budget-constrained operations. Both methods face challenges such as measurement accuracy, rotor accessibility, and the need for precise correction weights to avoid introducing new imbalances during the process.

Choosing the Right Balancing Method for Your Needs

Single-plane balancing is ideal for correcting heavy spots on rigid rotors with a single correction plane, offering a cost-effective solution for simple applications. Dynamic balancing addresses imbalances on flexible rotors by measuring and correcting in multiple planes, ensuring smoother operation and extended equipment life. Selecting the right balancing method depends on rotor geometry, operational speed, and precision requirements to optimize performance and reduce vibration-related damage.

Single-plane balancing Infographic

libterm.com

libterm.com