Axial load refers to the force applied along the longitudinal axis of a structural member, causing compression or tension. Understanding the distribution and impact of axial loads is crucial for ensuring the stability and safety of buildings, bridges, and mechanical components. Discover more about how axial loads influence structural integrity and design considerations in the rest of this article.

Table of Comparison

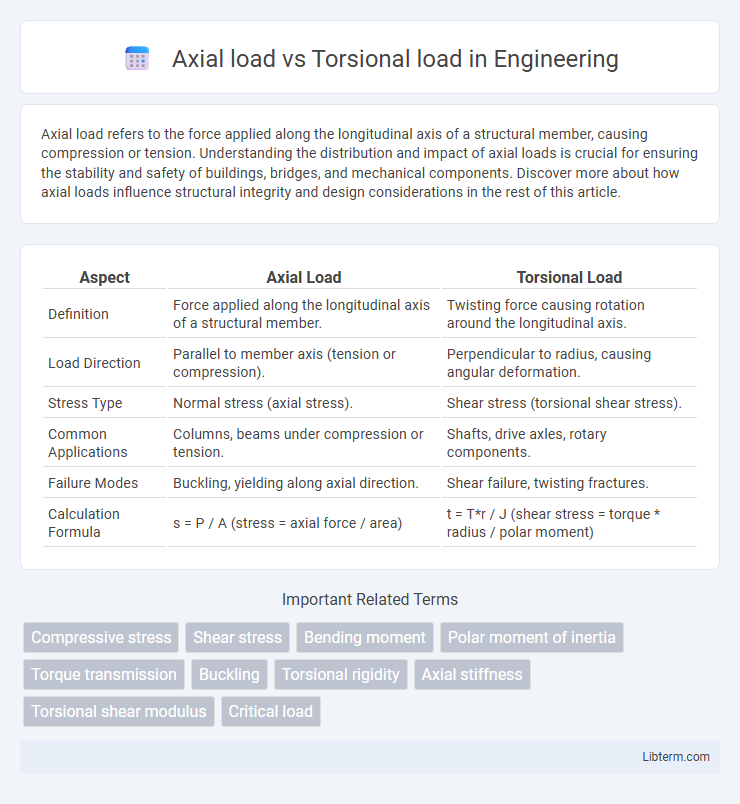

| Aspect | Axial Load | Torsional Load |

|---|---|---|

| Definition | Force applied along the longitudinal axis of a structural member. | Twisting force causing rotation around the longitudinal axis. |

| Load Direction | Parallel to member axis (tension or compression). | Perpendicular to radius, causing angular deformation. |

| Stress Type | Normal stress (axial stress). | Shear stress (torsional shear stress). |

| Common Applications | Columns, beams under compression or tension. | Shafts, drive axles, rotary components. |

| Failure Modes | Buckling, yielding along axial direction. | Shear failure, twisting fractures. |

| Calculation Formula | s = P / A (stress = axial force / area) | t = T*r / J (shear stress = torque * radius / polar moment) |

Introduction to Axial and Torsional Loads

Axial loads refer to forces applied along the longitudinal axis of an object, causing tension or compression, critical in structural elements like columns and beams. Torsional loads involve twisting forces around an object's axis, generating shear stress significant in shafts and rotating machinery components. Understanding the distinction between axial and torsional loads is essential for designing components to withstand mechanical stresses and ensure structural integrity.

Defining Axial Load: Concepts and Examples

Axial load refers to the force applied along the longitudinal axis of a structural member, causing tension or compression. Examples include the weight carried by a column in a building or the force exerted on a bridge cable. Understanding axial load is crucial for designing elements that can withstand direct linear forces without buckling or failing.

Understanding Torsional Load: Basics and Applications

Torsional load refers to the twisting force applied to an object, causing shear stress along its cross-section, which is crucial in shafts, drive axles, and structural components subjected to rotational motion. Understanding the magnitude and distribution of torsional load helps in designing materials and structures that resist failure due to twisting stresses, enhancing durability and performance. Applications in mechanical engineering and automotive industries rely on precise torsion analysis to prevent fatigue and maintain stability under operational loads.

Key Differences Between Axial and Torsional Loads

Axial loads act along the longitudinal axis of a structural member, causing compression or tension, while torsional loads induce twisting by applying torque around the axis. Axial loads primarily affect the member's length, resulting in elongation or shortening, whereas torsional loads generate shear stresses that deform the cross-section. Understanding these differences is critical for selecting appropriate materials and designing components to resist specific mechanical stresses in engineering applications.

Impact of Axial Load on Structural Integrity

Axial load directly affects the structural integrity by imposing compression or tension along the member's longitudinal axis, potentially leading to buckling or elongation that compromises stability. This load type induces normal stresses that can cause material deformation or failure if the axial capacity is exceeded. Engineers must carefully account for axial loads in design to ensure safety margins and prevent catastrophic structural collapse.

Effects of Torsional Load on Material Performance

Torsional load induces shear stress in materials, causing deformation that compromises structural integrity more severely than axial loading, which primarily produces normal stress along the material's axis. This shear stress can lead to microcracks and fatigue failures, significantly reducing the material's lifespan under cyclic torsion conditions. Materials with low shear strength or poor ductility experience accelerated wear and potential catastrophic failure when subjected to torsional loads.

Common Engineering Applications: Axial vs Torsional Loads

Axial loads primarily occur in structural columns, tension members, and shafts subjected to direct compression or tension forces, playing a critical role in bridges, buildings, and cranes. Torsional loads dominate in applications involving rotating elements such as drive shafts, propeller shafts, and torque transmission systems in automotive and aerospace engineering. Understanding the distinction between axial and torsional loads enables engineers to select appropriate materials and design components that ensure safety, durability, and efficient performance in mechanical and civil structures.

Failure Modes: Axial Load vs Torsional Load

Failure modes under axial load primarily involve tensile or compressive stresses that cause buckling, yielding, or fracture along the load axis, often resulting in material elongation or crushing. Under torsional load, failure typically manifests as shear stress leading to twisting, fatigue cracks, or torsional fracture, especially at stress concentrators or in ductile materials. Understanding these distinct failure mechanisms is critical for designing components resistant to specific load types, ensuring structural integrity and safety.

Methods for Measuring Axial and Torsional Loads

Methods for measuring axial loads commonly involve strain gauge load cells and hydraulic load cells, which convert mechanical force into electrical signals for precise quantification. Torsional loads are typically measured using torsion meters and rotary torque transducers that detect angular displacement and torque through strain gauges or magnetic sensors. Both types of measurements require careful calibration and consideration of environmental factors to ensure accurate load data in structural and mechanical applications.

Design Considerations for Managing Axial and Torsional Loads

Design considerations for managing axial and torsional loads prioritize material strength, geometry, and support conditions to prevent failure. Axial loads require careful evaluation of compressive, tensile, or buckling stresses, while torsional loads demand analysis of shear stresses and angular deformation. Optimizing shaft diameter, selecting appropriate materials, and incorporating stiffeners or coupling elements enhances resistance to combined axial and torsional stresses in mechanical systems.

Axial load Infographic

libterm.com

libterm.com