Finned tube heat exchangers enhance heat transfer efficiency by increasing the surface area for thermal exchange between fluids. These devices are widely used in HVAC systems, power plants, and refrigeration due to their compact size and ability to handle high-pressure fluids. Explore the rest of the article to discover how finned tube heat exchangers can optimize your thermal management solutions.

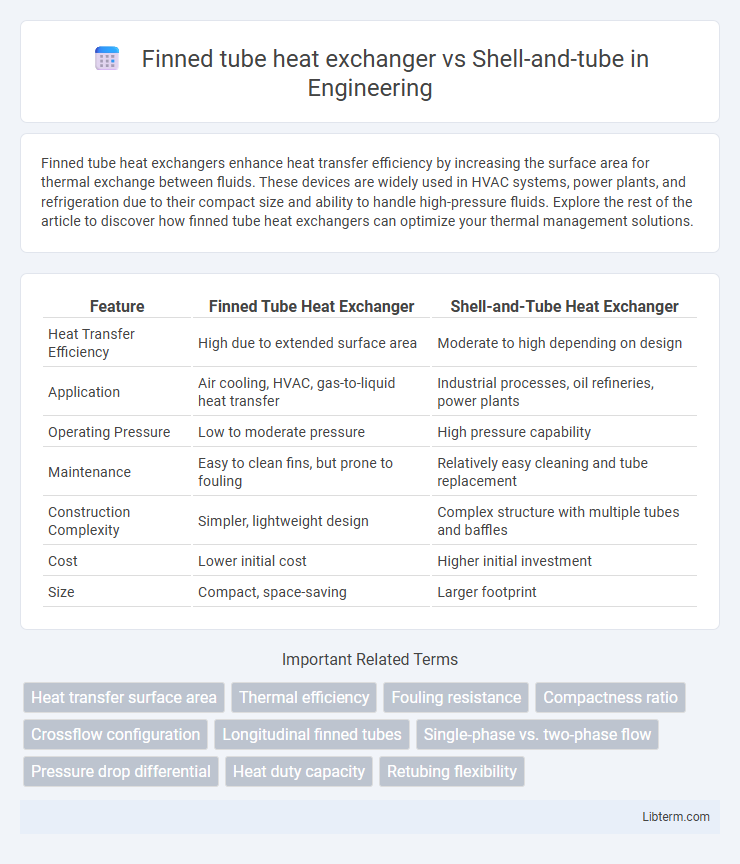

Table of Comparison

| Feature | Finned Tube Heat Exchanger | Shell-and-Tube Heat Exchanger |

|---|---|---|

| Heat Transfer Efficiency | High due to extended surface area | Moderate to high depending on design |

| Application | Air cooling, HVAC, gas-to-liquid heat transfer | Industrial processes, oil refineries, power plants |

| Operating Pressure | Low to moderate pressure | High pressure capability |

| Maintenance | Easy to clean fins, but prone to fouling | Relatively easy cleaning and tube replacement |

| Construction Complexity | Simpler, lightweight design | Complex structure with multiple tubes and baffles |

| Cost | Lower initial cost | Higher initial investment |

| Size | Compact, space-saving | Larger footprint |

Introduction to Finned Tube and Shell-and-Tube Heat Exchangers

Finned tube heat exchangers enhance heat transfer efficiency by increasing the surface area of the tubes with fins, making them ideal for applications requiring compact design and effective heat dissipation. Shell-and-tube heat exchangers consist of a series of tubes enclosed within a cylindrical shell, offering high durability and versatility for handling high-pressure fluids and large-scale heat transfer. Both types are widely used in industrial processes, with finned tube exchangers favored for air-cooling and shell-and-tube exchangers preferred for liquid-to-liquid heat exchange.

Core Design Differences

Finned tube heat exchangers feature extended surfaces with fins welded or extruded onto the tubes to enhance heat transfer by increasing the effective surface area, making them ideal for gas-to-liquid applications with lower heat transfer coefficients. Shell-and-tube heat exchangers consist of a bundle of smooth tubes enclosed within a cylindrical shell, facilitating heat exchange between two fluids at different pressures and temperatures, commonly used in high-pressure and high-temperature industrial processes. The core design difference lies in the presence of fins on the tubes in finned tube heat exchangers versus smooth tubes in shell-and-tube units, resulting in variations in heat transfer efficiency, fluid flow dynamics, and maintenance requirements.

Heat Transfer Efficiency Comparison

Finned tube heat exchangers enhance heat transfer efficiency by increasing the surface area through extended fins, facilitating improved thermal exchange in air-cooled applications. Shell-and-tube heat exchangers rely on fluid flow inside tubes and shell, delivering high heat transfer rates suitable for high-pressure and temperature conditions. The efficiency of finned tube exchangers excels in gas-to-liquid processes, while shell-and-tube designs maintain superior performance in liquid-to-liquid heat transfer scenarios.

Material Selection and Durability

Finned tube heat exchangers often use copper or aluminum fins combined with steel or copper tubes, enhancing heat transfer efficiency while maintaining lightweight durability. Shell-and-tube heat exchangers typically feature carbon steel or stainless steel shells and tubes for superior resistance to high pressure and corrosive environments. Material selection for both types directly impacts lifespan and maintenance frequency, with stainless steel offering enhanced corrosion resistance and durability in harsh industrial conditions.

Size and Space Requirements

Finned tube heat exchangers typically require less space than shell-and-tube exchangers due to their compact design and enhanced heat transfer surface area from fins. Shell-and-tube heat exchangers are generally larger and bulkier, as they need extensive shell volume and multiple tubes to achieve similar heat transfer efficiency. The smaller footprint of finned tube exchangers makes them ideal for applications with limited size and space constraints.

Maintenance and Cleaning Considerations

Finned tube heat exchangers feature extended surfaces that increase heat transfer efficiency but require regular cleaning to prevent fouling in tight fin spaces, which can be labor-intensive. Shell-and-tube heat exchangers offer easier access to individual tubes for inspection, maintenance, and cleaning, often utilizing mechanical or chemical cleaning methods to clear scaling and deposits. Maintenance frequency depends on the operating environment, with fouling-prone processes needing more frequent interventions to maintain optimal performance.

Cost Analysis: Initial and Operational

Finned tube heat exchangers typically have lower initial costs due to their compact design and reduced material usage compared to shell-and-tube exchangers, which require more extensive fabrication and larger space. Operational expenses for finned tube systems are generally lower in applications involving air or gas cooling because of improved heat transfer efficiency and reduced maintenance needs. However, shell-and-tube exchangers may incur higher operational costs due to cleaning complexity and potential fouling in liquid-to-liquid heat transfer scenarios, impacting long-term profitability.

Application Areas and Industry Use Cases

Finned tube heat exchangers excel in HVAC systems, power plants, and air cooling applications due to their enhanced surface area that improves heat transfer efficiency in gas-to-air processes. Shell-and-tube heat exchangers are widely used in petrochemical, oil refining, and chemical industries for high-pressure, high-temperature fluid-to-fluid heat exchange, offering robust performance and easy maintenance. Both types serve critical roles, with finned tubes preferred for air cooling and shell-and-tube favored for complex liquid processing and industrial-scale heat exchange.

Advantages and Disadvantages

Finned tube heat exchangers offer enhanced heat transfer efficiency due to increased surface area, making them ideal for applications with limited space and low fluid flow rates. Shell-and-tube heat exchangers provide robust design and versatility suited for high-pressure and high-temperature conditions but typically require more space and maintenance. While finned tube units excel in compactness and cost-effectiveness, shell-and-tube types deliver superior durability and easier scalability for industrial processes.

Choosing the Right Heat Exchanger for Your Needs

Finned tube heat exchangers excel in applications requiring enhanced heat transfer efficiency with limited space, as their fins increase surface area and improve thermal performance. Shell-and-tube heat exchangers offer robustness and versatility, making them suitable for high-pressure and high-temperature processes in industries such as oil refining and chemical processing. Selecting the right heat exchanger depends on factors like operating conditions, maintenance requirements, space constraints, and thermal duty to optimize energy efficiency and system longevity.

Finned tube heat exchanger Infographic

libterm.com

libterm.com