Electromechanics integrates electrical and mechanical systems to create devices that convert electrical energy into mechanical motion or vice versa, enabling innovations in robotics, automation, and control systems. This multidisciplinary field leverages principles from electronics, mechanics, and computer science to design efficient, reliable machinery for industries such as manufacturing, automotive, and aerospace. Explore the article to discover how electromechanics impacts modern technology and enhances your daily life.

Table of Comparison

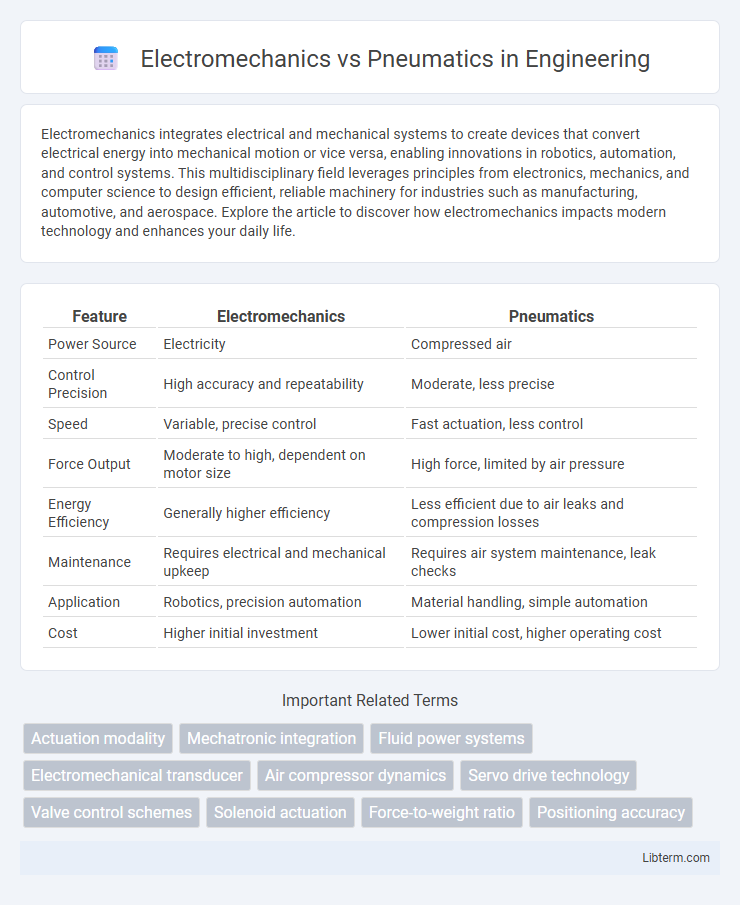

| Feature | Electromechanics | Pneumatics |

|---|---|---|

| Power Source | Electricity | Compressed air |

| Control Precision | High accuracy and repeatability | Moderate, less precise |

| Speed | Variable, precise control | Fast actuation, less control |

| Force Output | Moderate to high, dependent on motor size | High force, limited by air pressure |

| Energy Efficiency | Generally higher efficiency | Less efficient due to air leaks and compression losses |

| Maintenance | Requires electrical and mechanical upkeep | Requires air system maintenance, leak checks |

| Application | Robotics, precision automation | Material handling, simple automation |

| Cost | Higher initial investment | Lower initial cost, higher operating cost |

Introduction to Electromechanics and Pneumatics

Electromechanics integrates electrical and mechanical systems to create devices such as motors, actuators, and sensors, enabling precise control and automation in various industrial applications. Pneumatics utilizes compressed air to power mechanical motion, commonly employed in manufacturing for tasks requiring speed and reliability with components like cylinders and valves. Understanding the fundamental principles of both technologies allows engineers to select optimal solutions for automation, balancing efficiency, cost, and maintenance requirements.

Core Principles of Electromechanics

Electromechanics integrates electrical and mechanical processes to design systems where electrical energy controls mechanical movement, primarily using motors, actuators, and sensors. The core principles involve electromagnetic induction, conversion of electrical signals into mechanical motion, and precise control through electrical circuits and controllers. This approach enables high efficiency, accuracy, and automation in various applications, contrasting with the fluid power principles underlying pneumatics.

Fundamentals of Pneumatic Systems

Pneumatic systems rely on compressed air to transmit and control energy, utilizing components such as compressors, valves, actuators, and air preparation units. The fundamental principle involves converting air pressure into mechanical motion, enabling precise control in industrial automation and machinery. Compared to electromechanics, pneumatics offer advantages like simplicity, cost-effectiveness, and rapid response, but operate within pressure and force limitations dictated by system design parameters.

Key Differences: Electromechanics vs Pneumatics

Electromechanics combines electrical and mechanical processes to control devices using motors, sensors, and actuators, offering precise motion control and high efficiency in automation systems. Pneumatics uses compressed air to generate mechanical motion, favored for simplicity, lower cost, and rapid actuation in applications requiring less precision and smoothness. Key differences include energy sources--electric power versus compressed air--and performance factors like accuracy, speed, maintenance needs, and application complexity.

Energy Sources and Efficiency Comparison

Electromechanics relies on electrical energy converted into mechanical motion using motors and actuators, offering precise control and high energy efficiency, often exceeding 80% efficiency in well-designed systems. Pneumatics utilizes compressed air as its energy source, which introduces energy losses due to air compression, leakage, and exhaust, typically achieving lower overall efficiency around 10-30%. The electrical energy used in electromechanical systems tends to be more efficiently converted to work, while pneumatic systems are favored where simplicity and rapid motion are prioritized despite lower energy efficiency.

Application Areas in Modern Industries

Electromechanics are extensively used in robotics, automated manufacturing, and precision control systems due to their high accuracy and integration with electronic control units. Pneumatics dominate applications requiring rapid, repetitive motion such as packaging, material handling, and assembly lines because of their simplicity, cost-effectiveness, and reliability in harsh environments. Modern industries often combine both technologies to optimize efficiency, with electromechanics providing precise control and pneumatics offering robust actuation in sectors like automotive, aerospace, and consumer goods.

Advantages of Electromechanical Systems

Electromechanical systems offer precise control and high efficiency, making them ideal for applications requiring accurate positioning and variable speed operation. These systems provide better energy utilization and lower maintenance compared to pneumatics, as they do not rely on compressed air, reducing operational costs and environmental impact. The ability to integrate with digital controllers also enhances automation capabilities and system responsiveness in complex industrial processes.

Benefits and Limitations of Pneumatic Technology

Pneumatic technology offers benefits such as simplicity, reliability, cost-effectiveness, and fast actuation, making it ideal for repetitive tasks and environments requiring explosion-proof systems. However, pneumatic systems have limitations including lower precision, limited force control, energy inefficiency due to compressed air leakage, and higher noise levels compared to electromechanical alternatives. Routine maintenance of compressors and air lines is essential to prevent system failures and ensure optimal pneumatic performance.

Selection Criteria: When to Use Each System

Electromechanics is ideal for applications requiring precise control, high force, and automation integration, such as robotics and CNC machinery, due to its ability to deliver consistent, accurate movements. Pneumatics excels in environments needing rapid, repetitive motion with simpler control systems, especially where cleanliness and safety are prioritized, like in food processing or packaging industries. Selection depends on factors including load requirements, speed, environmental conditions, maintenance complexity, and system cost, with electromechanics suited for high-precision tasks and pneumatics favored for lightweight, high-speed operations.

Future Trends in Automation: Electromechanics vs Pneumatics

Future trends in automation highlight a growing preference for electromechanics due to its precision, energy efficiency, and integration with digital control systems, which enhance smart manufacturing capabilities. Pneumatics remain valuable for applications requiring high-speed and cost-effective actuation but face limitations in adaptability and energy consumption compared to electromechanical systems. Advancements in electromechanical components, such as servo motors and sensors, are accelerating their adoption over traditional pneumatic solutions in Industry 4.0 environments.

Electromechanics Infographic

libterm.com

libterm.com