Stirling is a historic city in central Scotland known for its iconic castle and rich medieval heritage. Its strategic location offers breathtaking views of the surrounding landscapes and important landmarks tied to Scotland's past. Discover how Stirling's unique blend of history and culture can enhance your next travel experience in the full article.

Table of Comparison

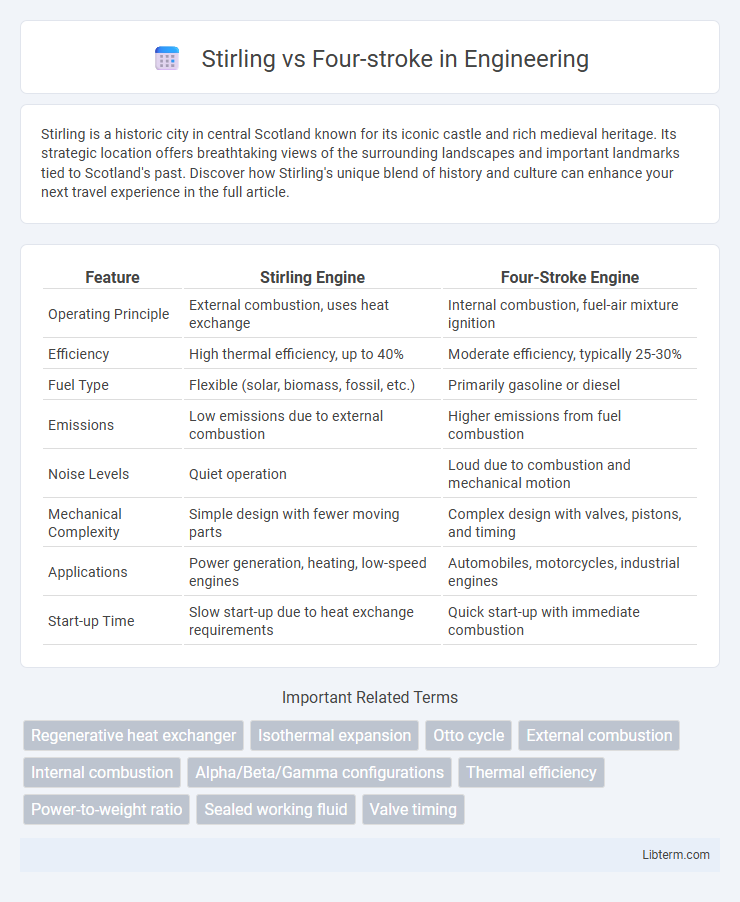

| Feature | Stirling Engine | Four-Stroke Engine |

|---|---|---|

| Operating Principle | External combustion, uses heat exchange | Internal combustion, fuel-air mixture ignition |

| Efficiency | High thermal efficiency, up to 40% | Moderate efficiency, typically 25-30% |

| Fuel Type | Flexible (solar, biomass, fossil, etc.) | Primarily gasoline or diesel |

| Emissions | Low emissions due to external combustion | Higher emissions from fuel combustion |

| Noise Levels | Quiet operation | Loud due to combustion and mechanical motion |

| Mechanical Complexity | Simple design with fewer moving parts | Complex design with valves, pistons, and timing |

| Applications | Power generation, heating, low-speed engines | Automobiles, motorcycles, industrial engines |

| Start-up Time | Slow start-up due to heat exchange requirements | Quick start-up with immediate combustion |

Overview of Stirling and Four-Stroke Engines

Stirling engines operate on external combustion, using a closed-cycle regenerative thermodynamic process to convert heat into mechanical work with high efficiency and low emissions. Four-stroke engines are internal combustion engines that complete power cycles in four distinct strokes: intake, compression, combustion, and exhaust, widely used in automotive applications due to their power density and responsiveness. Stirling engines excel in quiet operation and fuel flexibility, whereas four-stroke engines dominate in performance and widespread practical application.

Fundamental Operating Principles

Stirling engines operate on external combustion by cyclically compressing and expanding a fixed amount of gas using temperature differences, enabling efficient heat-to-work conversion with minimal emissions. Four-stroke engines rely on internal combustion cycles--intake, compression, power, and exhaust--within the cylinder to convert fuel into mechanical energy directly through controlled ignition. Stirling's closed-system and external heat source contrast with the four-stroke's open, fueled combustion process, influencing efficiency, environmental impact, and application scope.

Efficiency Comparison

Stirling engines exhibit higher thermal efficiency compared to four-stroke internal combustion engines due to their external combustion process, which allows for better heat recovery and lower energy losses. While four-stroke engines typically achieve efficiencies between 25% and 30%, Stirling engines can reach efficiencies exceeding 40% under optimal conditions. The closed-cycle operation and continuous heat input of Stirling engines contribute to their superior fuel utilization and reduced emissions.

Power Output and Performance

Stirling engines typically produce lower power output compared to four-stroke internal combustion engines due to their slower thermodynamic cycles and reliance on external heat sources. Four-stroke engines achieve higher performance levels with rapid combustion events, delivering greater horsepower and torque suitable for automotive and industrial applications. Despite lower peak power, Stirling engines offer superior efficiency and quieter operation, making them ideal for specialized uses where fuel flexibility and emissions are critical.

Fuel Types and Flexibility

Stirling engines operate on external combustion, allowing them to use a wide variety of fuel types including solar, biomass, natural gas, and even waste heat, making them highly fuel-flexible. Four-stroke engines rely on internal combustion, primarily designed for gasoline, diesel, or biofuels, limiting fuel adaptability compared to Stirling engines. The external combustion process in Stirling engines enhances environmental versatility and reduces emissions while four-stroke engines offer efficient performance but with stricter fuel requirements.

Environmental Impact

Stirling engines produce lower emissions compared to four-stroke engines due to external combustion with cleaner fuel options and continuous combustion processes. Four-stroke engines typically emit higher levels of nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter because of internal combustion with fossil fuels. Stirling engines offer greater potential for reduced environmental impact through lower greenhouse gas emissions and quieter operation, making them suitable for sustainable energy applications.

Mechanical Complexity and Maintenance

Stirling engines feature fewer moving parts and sealed combustion chambers, resulting in lower mechanical complexity and reduced maintenance compared to four-stroke engines. Four-stroke engines have numerous components like valves, camshafts, and fuel injection systems that require regular adjustments and oil changes. The simpler design of Stirling engines typically leads to longer service intervals and lower upkeep costs.

Applications in Industry and Transport

Stirling engines are commonly used in renewable energy systems, such as solar power plants and submarine propulsion, due to their high efficiency and ability to run on various heat sources. Four-stroke engines dominate the automotive and heavy machinery industries because of their robust power output, fuel efficiency, and widespread fueling infrastructure. Industrial applications favor four-stroke engines for construction equipment and generators, while Stirling engines find niche roles in low-noise, low-emission environments like submarines and auxiliary power units.

Historical Development and Adoption

The Stirling engine, invented by Robert Stirling in 1816, was initially developed as a safer alternative to steam engines, featuring external combustion and a closed-cycle process that improved efficiency and safety. In contrast, the four-stroke internal combustion engine, patented by Nikolaus Otto in 1876, gained rapid adoption due to its compact design, higher power-to-weight ratio, and suitability for automotive applications. Historical adoption favored four-stroke engines for transportation and industrial use, while Stirling engines found niche applications in specialized areas like submarines and solar power generation due to their quiet operation and fuel flexibility.

Future Prospects and Innovations

Stirling engines, known for high efficiency and low emissions, are gaining momentum in renewable energy applications and micro combined heat and power (CHP) systems, driven by advances in materials and heat exchanger technologies. Four-stroke engines dominate automotive and industrial sectors, but ongoing innovations in fuel injection, combustion optimization, and hybrid integration aim to reduce emissions and improve fuel economy. Emerging trends indicate a convergence where Stirling engines could complement four-stroke systems in hybrid setups, enhancing overall energy sustainability and performance resilience.

Stirling Infographic

libterm.com

libterm.com