Hardness measures a material's resistance to deformation, commonly assessed by scratch, indentation, or abrasion tests, impacting durability and wear resistance. Different scales like Mohs, Vickers, or Rockwell provide specific insights depending on the application and material type. Explore the rest of the article to understand how hardness affects your material selection and performance considerations.

Table of Comparison

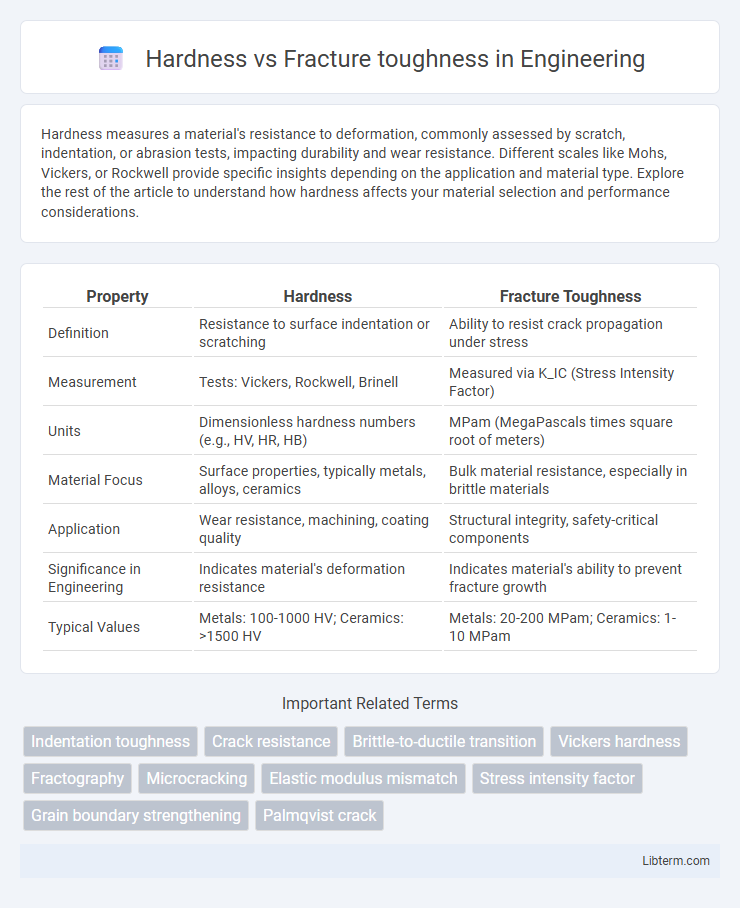

| Property | Hardness | Fracture Toughness |

|---|---|---|

| Definition | Resistance to surface indentation or scratching | Ability to resist crack propagation under stress |

| Measurement | Tests: Vickers, Rockwell, Brinell | Measured via K_IC (Stress Intensity Factor) |

| Units | Dimensionless hardness numbers (e.g., HV, HR, HB) | MPam (MegaPascals times square root of meters) |

| Material Focus | Surface properties, typically metals, alloys, ceramics | Bulk material resistance, especially in brittle materials |

| Application | Wear resistance, machining, coating quality | Structural integrity, safety-critical components |

| Significance in Engineering | Indicates material's deformation resistance | Indicates material's ability to prevent fracture growth |

| Typical Values | Metals: 100-1000 HV; Ceramics: >1500 HV | Metals: 20-200 MPam; Ceramics: 1-10 MPam |

Understanding Hardness: Definition and Importance

Hardness measures a material's resistance to deformation, particularly permanent indentation, and is crucial for assessing wear resistance and durability. It directly impacts a material's performance in applications requiring surface strength, such as cutting tools and protective coatings. Understanding hardness allows engineers to select appropriate materials that maintain structural integrity under mechanical stress and abrasive environments.

Fracture Toughness Explained: Key Concepts

Fracture toughness measures a material's ability to resist crack propagation under stress, quantified by critical stress intensity factor (K_IC) or energy-based parameters like G_IC. Unlike hardness, which indicates surface resistance to indentation or wear, fracture toughness reflects a material's intrinsic resistance to catastrophic failure and crack growth. Key concepts include stress intensity factors, crack tip plasticity, and energy absorption, essential for predicting component durability in engineering and materials science.

How Hardness and Fracture Toughness Differ

Hardness measures a material's resistance to localized plastic deformation or indentation, typically evaluated through tests like Rockwell or Vickers. Fracture toughness quantifies a material's ability to resist crack propagation and absorb energy before fracturing, expressed as K_IC in units of MPam. While hardness indicates surface durability and wear resistance, fracture toughness reflects the material's ability to withstand structural stresses without catastrophic failure.

Testing Methods for Hardness

Hardness testing methods, such as the Rockwell, Vickers, and Brinell tests, measure a material's resistance to indentation, providing crucial data on surface durability and wear resistance. These tests differ in scale and application, with Rockwell using a steel ball or diamond cone under a fixed load, Vickers employing a diamond pyramid indenter for micro-scale precision, and Brinell utilizing a large steel ball for softer materials. While hardness tests offer quick and reproducible results, they do not directly correlate with fracture toughness, which is evaluated through fracture mechanics methods like the Charpy impact or crack propagation tests to assess a material's resistance to crack initiation and growth.

Measuring Fracture Toughness: Common Techniques

Measuring fracture toughness typically involves techniques such as the Single Edge Notched Bend (SENB) test, the Compact Tension (CT) test, and the Chevron Notch test, which assess a material's resistance to crack propagation under stress. These methods provide critical parameters like K_IC and J_IC, essential for predicting failure in components subjected to mechanical loads. Accurate fracture toughness measurement is crucial for designing materials with optimal balance between hardness and resistance to brittle fracture.

Relationship Between Hardness and Fracture Toughness

Hardness and fracture toughness are fundamental mechanical properties that often exhibit an inverse relationship in materials science, where increased hardness typically leads to reduced fracture toughness due to a material's limited ability to deform plastically before fracturing. Fracture toughness quantifies a material's resistance to crack propagation, while hardness measures resistance to localized plastic deformation, making materials with high hardness more brittle and susceptible to crack initiation. Understanding this trade-off is critical for selecting materials in high-stress applications where both wear resistance and structural integrity are required.

Applications Requiring High Hardness

Applications requiring high hardness, such as cutting tools and wear-resistant coatings, prioritize materials like carbides and ceramics due to their exceptional resistance to deformation and surface wear. While these materials exhibit superior hardness, their fracture toughness is typically lower, making them more susceptible to crack propagation under impact or sudden stress. Therefore, optimizing high-hardness materials involves balancing hardness with sufficient fracture toughness to prevent brittle failure in demanding operational environments.

Industries Relying on Fracture Toughness

Industries such as aerospace, automotive, and construction prioritize fracture toughness to ensure materials withstand impacts and prevent catastrophic failure under stress. Fracture toughness gauges a material's resistance to crack propagation, crucial for safety-critical components exposed to dynamic loads and harsh environments. Although hardness indicates surface resistance to deformation, high fracture toughness is essential for durability and reliability in structural applications.

Material Selection: Balancing Hardness and Toughness

Material selection in engineering requires balancing hardness and fracture toughness to ensure both wear resistance and structural integrity. Hardness measures a material's resistance to surface deformation, while fracture toughness quantifies its ability to resist crack propagation under stress. Optimizing this balance is critical in applications such as aerospace and automotive industries, where components must withstand mechanical loads without failure.

Future Trends in Hardness and Fracture Toughness Research

Future trends in hardness and fracture toughness research emphasize the development of advanced materials with optimized microstructures to achieve superior mechanical properties. Innovations in nanotechnology and additive manufacturing enable precise control over grain size and phase distribution, enhancing both hardness and fracture toughness simultaneously. Emerging computational modeling techniques and machine learning algorithms accelerate the discovery of novel alloys and composites with tailored durability for extreme environments.

Hardness Infographic

libterm.com

libterm.com