Tool steels are specially formulated alloys designed to withstand high stresses, temperatures, and wear during cutting and shaping operations. Their unique composition provides excellent hardness, toughness, and resistance to deformation, making them essential for manufacturing durable and precise tools. Discover how selecting the right tool steel can enhance Your machining processes and read on to explore the various types and applications.

Table of Comparison

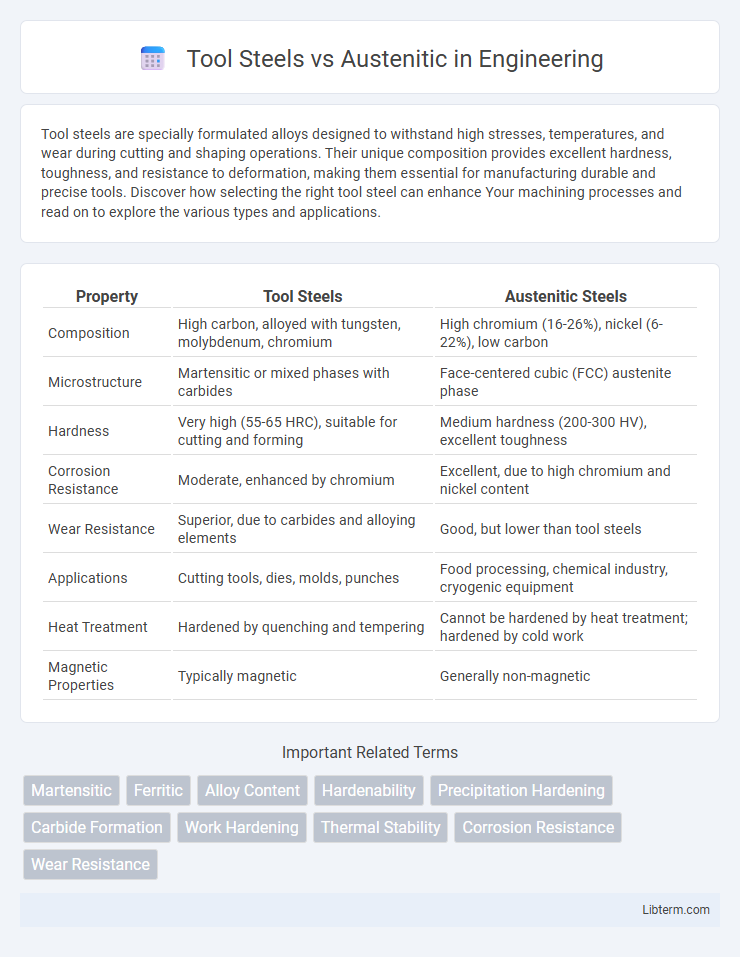

| Property | Tool Steels | Austenitic Steels |

|---|---|---|

| Composition | High carbon, alloyed with tungsten, molybdenum, chromium | High chromium (16-26%), nickel (6-22%), low carbon |

| Microstructure | Martensitic or mixed phases with carbides | Face-centered cubic (FCC) austenite phase |

| Hardness | Very high (55-65 HRC), suitable for cutting and forming | Medium hardness (200-300 HV), excellent toughness |

| Corrosion Resistance | Moderate, enhanced by chromium | Excellent, due to high chromium and nickel content |

| Wear Resistance | Superior, due to carbides and alloying elements | Good, but lower than tool steels |

| Applications | Cutting tools, dies, molds, punches | Food processing, chemical industry, cryogenic equipment |

| Heat Treatment | Hardened by quenching and tempering | Cannot be hardened by heat treatment; hardened by cold work |

| Magnetic Properties | Typically magnetic | Generally non-magnetic |

Introduction to Tool Steels and Austenitic Steels

Tool steels are high-carbon, alloy steels designed for high hardness, wear resistance, and heat resistance, commonly used in cutting, shaping, and forming tools. Austenitic steels, primarily composed of iron, chromium (typically 16-26%), and nickel, exhibit excellent corrosion resistance, high ductility, and non-magnetic properties at room temperature. Both steel types serve distinct industrial purposes: tool steels excel in durability under mechanical stress, while austenitic steels are favored for applications requiring superior corrosion protection and toughness.

Chemical Composition Differences

Tool steels contain high carbon content (typically 0.5-1.5%) combined with elements like chromium, vanadium, and molybdenum to enhance hardness, wear resistance, and toughness. Austenitic stainless steels feature a lower carbon content (usually less than 0.1%) and high nickel (8-20%) and chromium (16-26%) concentrations, providing excellent corrosion resistance and ductility. The significant differences in carbon level and alloying elements distinctly influence their mechanical properties and applications.

Microstructural Characteristics

Tool steels exhibit a microstructure primarily composed of martensite and carbides, providing high hardness and wear resistance essential for cutting and shaping tools. Austenitic stainless steels feature a face-centered cubic (FCC) structure with high chromium and nickel content, resulting in excellent corrosion resistance and toughness but lower hardness compared to tool steels. The key distinction lies in tool steels' hard, carbide-rich microstructure versus the ductile, single-phase austenitic microstructure optimized for corrosion resistance and formability.

Mechanical Properties Comparison

Tool steels exhibit superior hardness, wear resistance, and high tensile strength compared to austenitic stainless steels, making them ideal for cutting, shaping, and molding applications. Austenitic steels provide excellent toughness, ductility, and corrosion resistance but generally have lower tensile strength and hardness than tool steels. The high carbon and alloy content in tool steels enhances mechanical properties such as hardness and fatigue resistance, whereas austenitic steels rely on their face-centered cubic (FCC) structure for improved toughness and corrosion performance.

Heat Treatment Responses

Tool steels exhibit high hardenability and respond well to heat treatments such as quenching and tempering, which enhance their hardness, wear resistance, and toughness. Austenitic stainless steels, characterized by high chromium and nickel content, generally do not harden by heat treatment but instead rely on work hardening and solution annealing to improve ductility and corrosion resistance. The differing microstructures of tool steels (martensitic) and austenitic steels (face-centered cubic) dictate their distinct thermal responses and applications in high-stress environments.

Corrosion and Wear Resistance

Tool steels exhibit superior wear resistance due to their high hardness and carbide content, making them ideal for cutting and shaping applications. Austenitic steels, characterized by their high chromium and nickel content, offer exceptional corrosion resistance in various environments, including acidic and marine conditions. The choice between tool steels and austenitic steels depends on the balance required between wear resistance and corrosion resistance for specific industrial uses.

Common Applications of Tool Steels and Austenitic Steels

Tool steels are widely used in applications requiring high hardness, wear resistance, and toughness, such as cutting tools, molds, dies, and punches in manufacturing industries. Austenitic steels find common applications in environments demanding excellent corrosion resistance and formability, including kitchen equipment, chemical processing plants, and medical devices. The distinct microstructures of tool steels and austenitic stainless steels determine their specialized uses in industrial tooling and corrosion-resistant components respectively.

Machinability and Workability Comparison

Tool steels exhibit high hardness and wear resistance but generally have lower machinability due to their carbon and alloy content, which makes cutting and shaping more challenging. Austenitic stainless steels offer superior workability and corrosion resistance, featuring better machinability through processes such as drilling and milling, although they can work harden rapidly. Choosing between tool steels and austenitic grades depends on balancing the need for mechanical strength against ease of fabrication in industrial applications.

Cost Considerations and Lifecycle

Tool steels generally exhibit higher upfront costs due to alloying elements like tungsten, molybdenum, and vanadium, which enhance hardness and wear resistance, extending tool life and reducing replacement frequency. Austenitic steels, primarily stainless with high chromium and nickel content, tend to have lower initial costs but may suffer from faster wear in high-stress tooling applications, potentially increasing maintenance expenses and total lifecycle cost. Evaluating cost-effectiveness requires balancing the premium price of tool steels against their superior durability and longer operational lifespan compared to austenitic alternatives.

Selecting Between Tool Steels and Austenitic Steels

Selecting between tool steels and austenitic steels depends on the required mechanical properties and application environment. Tool steels offer superior hardness, wear resistance, and toughness, making them ideal for cutting, shaping, and high-stress tooling applications. Austenitic steels, primarily stainless alloys like 304 and 316, provide excellent corrosion resistance and formability, suitable for environments exposed to oxidation or chemical exposure.

Tool Steels Infographic

libterm.com

libterm.com