Induction hardening is a precise heat treatment process that enhances the surface hardness of steel components by rapidly heating them with an alternating magnetic field followed by immediate quenching. This technique significantly improves wear resistance and fatigue strength while maintaining a tough and ductile core. Discover how your manufacturing process can benefit from induction hardening by exploring the rest of this article.

Table of Comparison

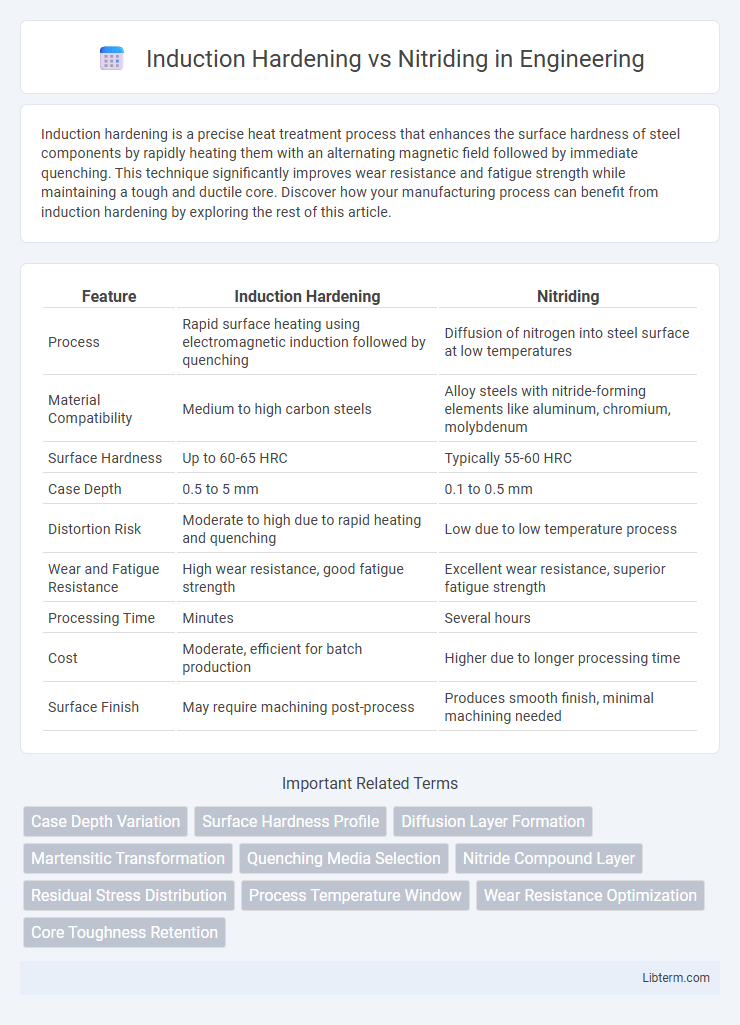

| Feature | Induction Hardening | Nitriding |

|---|---|---|

| Process | Rapid surface heating using electromagnetic induction followed by quenching | Diffusion of nitrogen into steel surface at low temperatures |

| Material Compatibility | Medium to high carbon steels | Alloy steels with nitride-forming elements like aluminum, chromium, molybdenum |

| Surface Hardness | Up to 60-65 HRC | Typically 55-60 HRC |

| Case Depth | 0.5 to 5 mm | 0.1 to 0.5 mm |

| Distortion Risk | Moderate to high due to rapid heating and quenching | Low due to low temperature process |

| Wear and Fatigue Resistance | High wear resistance, good fatigue strength | Excellent wear resistance, superior fatigue strength |

| Processing Time | Minutes | Several hours |

| Cost | Moderate, efficient for batch production | Higher due to longer processing time |

| Surface Finish | May require machining post-process | Produces smooth finish, minimal machining needed |

Introduction to Induction Hardening and Nitriding

Induction hardening is a heat treatment process that uses electromagnetic induction to rapidly heat the surface of steel components, followed by rapid quenching to increase hardness and wear resistance. Nitriding involves diffusing nitrogen into the steel surface at lower temperatures, creating a hard, wear-resistant layer without the need for quenching. Both methods enhance surface hardness but differ in heat application, treatment depth, and resulting microstructure, making them suitable for distinct industrial applications.

Overview of Surface Hardening Techniques

Induction hardening uses electromagnetic induction to rapidly heat the metal surface, followed by quenching, resulting in a hardened outer layer with a tough core, ideal for gears and shafts. Nitriding introduces nitrogen into the steel surface at lower temperatures, creating a hard, wear-resistant case without distortion, suitable for complex shapes and components requiring high fatigue strength. Both methods enhance surface hardness and wear resistance but differ in processing time, thermal impact, and metallurgical effects.

How Induction Hardening Works

Induction hardening works by using electromagnetic induction to rapidly heat the surface of a metal part, typically steel, to a temperature above its transformation range, followed by immediate quenching to create a hardened martensitic layer. This process targets specific areas, enhancing wear resistance and fatigue strength without affecting the core properties. Compared to nitriding, induction hardening provides faster processing times and deeper hardened layers, making it ideal for components subjected to high stress and impact.

Nitriding Process Explained

Nitriding is a surface hardening process that introduces nitrogen into the steel's surface at temperatures typically between 500degC and 550degC, creating a hard, wear-resistant nitride layer without the need for quenching. This diffusion-based technique improves fatigue strength, corrosion resistance, and surface hardness while maintaining core toughness. Common nitriding methods include gas nitriding, plasma nitriding, and salt bath nitriding, each offering precise control over case depth and compound layer formation.

Key Differences Between Induction Hardening and Nitriding

Induction hardening uses electromagnetic induction to rapidly heat the steel surface followed by quenching, creating a hardened layer with improved wear resistance and fatigue strength; it is a fast, localized process ideal for large batch production. Nitriding introduces nitrogen into the metal surface at lower temperatures in a controlled atmosphere, forming a hard, wear-resistant nitride layer without quenching, resulting in minimal distortion and excellent corrosion resistance. Key differences include heat source and temperature, process duration, and post-treatment effects on metal microstructure and dimensional stability.

Material Suitability for Each Method

Induction hardening is ideal for carbon and low-alloy steels with sufficient hardenability, enabling precise surface hardening while maintaining a tough core. Nitriding suits alloy steels containing elements like aluminum, chromium, and molybdenum, which form hard nitrides, enhancing surface hardness without quenching. Material microstructure and chemical composition critically influence the effectiveness and durability outcomes of both heat treatment processes.

Applications in Industry

Induction hardening is widely used in automotive and aerospace industries for components like gears, shafts, and crankshafts requiring localized surface hardness and wear resistance. Nitriding is favored in heavy machinery and tooling industries for parts such as dies, molds, and valve components that need enhanced surface fatigue strength without distortion. Both processes improve durability, but selection depends on application-specific requirements like component geometry and thermal sensitivity.

Comparative Advantages and Disadvantages

Induction hardening offers rapid heating and precise control, resulting in a hardened surface layer with a tough core, ideal for high-volume production with minimal distortion. Nitriding provides superior wear resistance and corrosion protection through a diffusion process that creates a hard, nitrogen-rich surface without requiring quenching, though it requires longer processing times and is less suitable for high-strength steels. Induction hardening excels in applications demanding deep hardness and speed, while nitriding benefits parts needing enhanced fatigue strength and dimensional stability.

Cost and Efficiency Considerations

Induction hardening offers rapid, localized heating, making it highly efficient for short production runs but requires significant energy input and specialized equipment, leading to higher upfront costs. Nitriding, performed at lower temperatures over longer periods, provides superior surface wear resistance and dimensional stability with lower operational costs but demands extended processing time and more complex gas handling systems. Cost-effectiveness depends on batch size and application needs, with induction hardening favored for quick, targeted treatments and nitriding preferred for large volumes requiring durable, uniform surface coatings.

Selecting the Right Hardening Method for Your Needs

Induction hardening provides rapid surface hardening with precise control over depth and hardness, ideal for gears, shafts, and components requiring high wear resistance and toughness. Nitriding offers a slower, low-temperature diffusion process that enhances surface hardness and fatigue strength without the need for quenching, making it suitable for parts requiring dimensional stability and corrosion resistance. Selecting the right hardening method depends on factors such as material compatibility, desired surface properties, production speed, and cost efficiency.

Induction Hardening Infographic

libterm.com

libterm.com