Fatigue load refers to the repeated or fluctuating stresses that a material or structure undergoes over time, which can lead to progressive and localized damage eventually causing failure. Understanding fatigue load is crucial for predicting the lifespan and ensuring the safety of mechanical components and structures in various industries. Explore the rest of the article to learn how fatigue load impacts design and maintenance strategies.

Table of Comparison

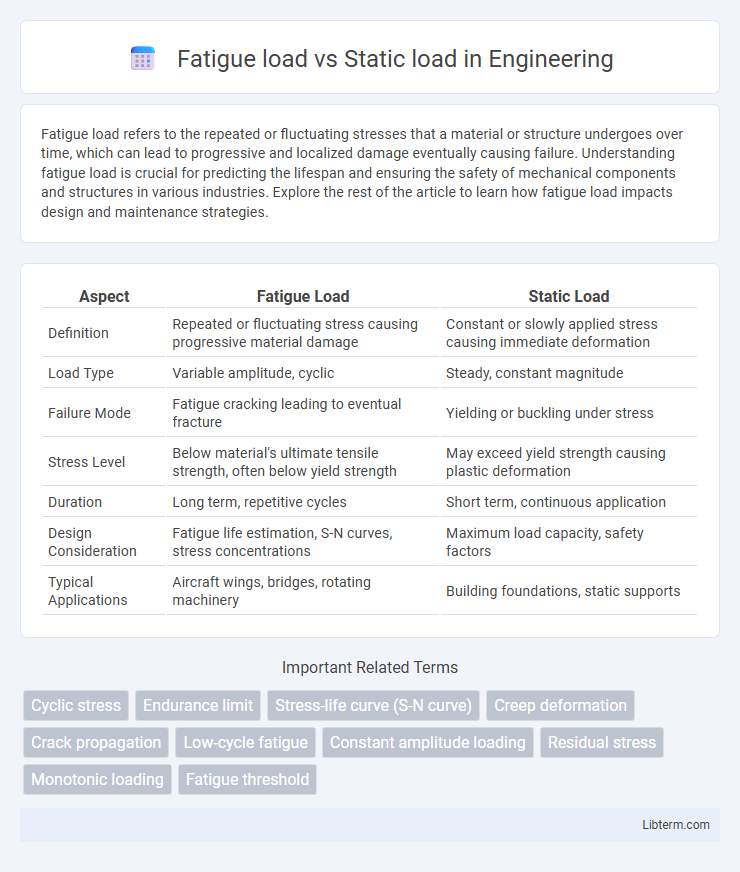

| Aspect | Fatigue Load | Static Load |

|---|---|---|

| Definition | Repeated or fluctuating stress causing progressive material damage | Constant or slowly applied stress causing immediate deformation |

| Load Type | Variable amplitude, cyclic | Steady, constant magnitude |

| Failure Mode | Fatigue cracking leading to eventual fracture | Yielding or buckling under stress |

| Stress Level | Below material's ultimate tensile strength, often below yield strength | May exceed yield strength causing plastic deformation |

| Duration | Long term, repetitive cycles | Short term, continuous application |

| Design Consideration | Fatigue life estimation, S-N curves, stress concentrations | Maximum load capacity, safety factors |

| Typical Applications | Aircraft wings, bridges, rotating machinery | Building foundations, static supports |

Introduction to Fatigue Load and Static Load

Fatigue load refers to the repeated or cyclic application of stress on a material, which can cause progressive and localized structural damage over time, often leading to failure even below the material's ultimate tensile strength. Static load involves a constant or slowly varying force applied to a structure or component, causing stress that remains relatively steady and can be analyzed for deformation and failure without considering time-based effects. Understanding the distinction between fatigue load and static load is essential in engineering design to ensure structural integrity and prevent unexpected failures.

Defining Fatigue Load

Fatigue load refers to repetitive or cyclic stresses applied to a material or structure over time, causing progressive and localized damage that can lead to failure well below the material's ultimate tensile strength. Unlike static load, which is a constant or slowly applied force maintaining a steady state, fatigue load fluctuates in magnitude, frequency, and direction, making it critical in the design of components subjected to dynamic environments like bridges, aircraft, and rotating machinery. Understanding the characteristics of fatigue load is essential for predicting fatigue life and preventing unexpected fractures in engineering applications.

Understanding Static Load

Static load refers to a constant or slowly varying force applied to a structure, causing stress that remains consistent over time, unlike fatigue load which involves repeated or fluctuating forces. Engineers analyze static load to ensure that materials and components can support maximum expected weight or pressure without permanent deformation. Understanding static load is crucial for designing safe buildings, bridges, and mechanical parts that must withstand predictable stresses under steady conditions.

Key Differences Between Fatigue and Static Loads

Fatigue load involves repeated or fluctuating stress cycles causing material degradation over time, while static load applies a constant or slowly varying force that tests a material's maximum strength at a specific moment. Fatigue loads typically lead to crack initiation and propagation due to cyclic stress ranges below the ultimate tensile strength, whereas static loads result in immediate deformation or failure once the material's yield strength is exceeded. Understanding the difference is crucial in structural engineering to design components that withstand long-term operational stresses without catastrophic failure.

Material Response to Fatigue Load

Fatigue load causes progressive and localized structural damage due to cyclic stresses that are typically below the material's ultimate tensile strength, leading to crack initiation and growth over time. In contrast, static load subjects the material to a constant or slowly varying force, resulting in immediate deformation or failure if the load exceeds the material's yield strength. Material response to fatigue load involves mechanisms such as microstructural changes, dislocation movements, and crack propagation that reduce fatigue life, making fatigue analysis critical for predicting component durability.

Material Performance Under Static Load

Material performance under static load involves the ability to withstand constant or slowly applied forces without permanent deformation or failure, focusing on properties like yield strength, ultimate tensile strength, and elasticity. Unlike fatigue load, which causes damage due to repeated cyclic stresses leading to crack initiation and propagation, static load primarily tests the material's capacity to maintain structural integrity under sustained pressure. Understanding static load behavior is critical for designing components that must endure long-term forces without experiencing creep, buckling, or plastic deformation.

Common Applications of Fatigue Load Analysis

Fatigue load analysis is critical in engineering applications such as aerospace, automotive, and bridge design, where materials are subjected to repeated cyclic stresses that can cause progressive damage over time. Unlike static load analysis that evaluates material behavior under constant or slowly varying forces, fatigue load analysis predicts lifespan and prevents failure caused by fluctuating loads. Components like aircraft wings, vehicle suspensions, and structural girders rely heavily on fatigue load analysis to ensure safety, durability, and performance under repetitive stress conditions.

Typical Uses of Static Load Assessment

Static load assessment is commonly used in structural engineering to evaluate the maximum load a material or structure can support without permanent deformation. Typical applications include designing buildings, bridges, and machinery to ensure safety under constant or slowly applied forces. This assessment helps in verifying compliance with safety codes and preventing structural failures due to overload.

Failure Mechanisms: Fatigue vs Static Loading

Fatigue load failure occurs due to repeated cyclic stresses causing microscopic cracks to initiate and propagate, eventually leading to material fracture even at stress levels below the material's ultimate tensile strength. Static load failure happens when a material is subjected to a constant or slowly applied load that exceeds its yield strength, causing immediate plastic deformation or brittle fracture without prior crack growth. Understanding the distinct failure mechanisms of fatigue and static loading is critical for designing components that resist crack initiation under cyclic conditions and sustain structural integrity under steady loads.

Design Considerations for Fatigue and Static Loads

Design considerations for fatigue load emphasize cyclic stress analysis to predict material lifespan under fluctuating forces, using S-N curves and Miner's rule for damage accumulation. Static load design prioritizes ultimate strength and safety factors to ensure structural integrity under constant or slowly varying forces without permanent deformation. Material selection, geometry, and load duration are critical parameters influencing resistance to both fatigue failure and static overload.

Fatigue load Infographic

libterm.com

libterm.com