Mixed flow pumps combine axial and radial flow characteristics, offering high efficiency and versatility in various industrial applications. Their design enables smooth fluid movement with moderate pressure and flow rates, making them ideal for water supply, HVAC, and irrigation systems. Discover how mixed flow pumps can enhance your operations and which models best suit your needs by reading the full article.

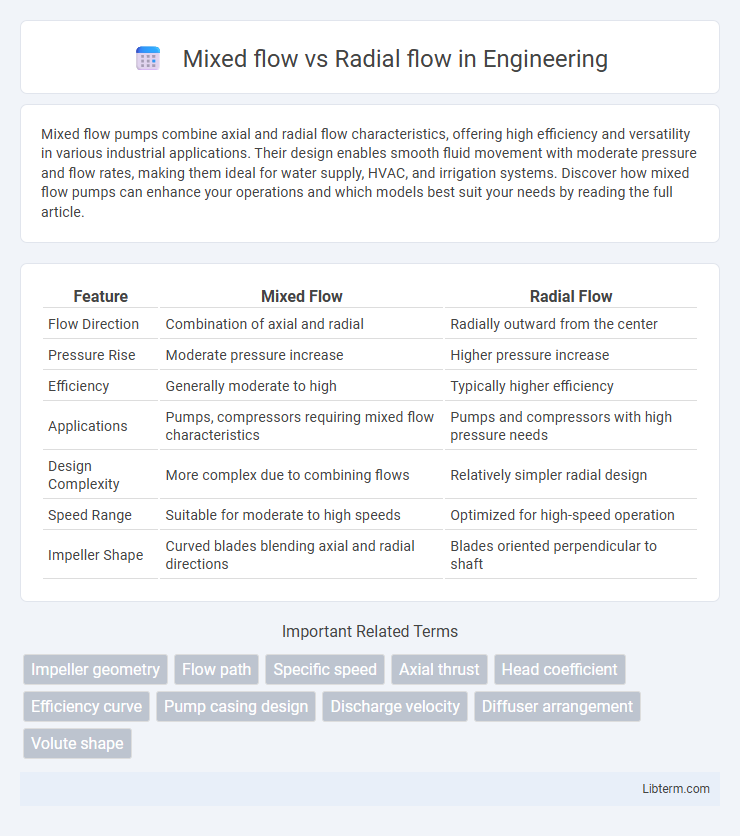

Table of Comparison

| Feature | Mixed Flow | Radial Flow |

|---|---|---|

| Flow Direction | Combination of axial and radial | Radially outward from the center |

| Pressure Rise | Moderate pressure increase | Higher pressure increase |

| Efficiency | Generally moderate to high | Typically higher efficiency |

| Applications | Pumps, compressors requiring mixed flow characteristics | Pumps and compressors with high pressure needs |

| Design Complexity | More complex due to combining flows | Relatively simpler radial design |

| Speed Range | Suitable for moderate to high speeds | Optimized for high-speed operation |

| Impeller Shape | Curved blades blending axial and radial directions | Blades oriented perpendicular to shaft |

Introduction to Flow Types

Mixed flow pumps combine axial and radial flow components, offering a balance between high flow rates and moderate pressure increases, commonly used in applications requiring efficient water movement. Radial flow pumps primarily move fluid perpendicular to the pump shaft, generating higher pressure but lower flow rates, ideal for high-head scenarios such as boiler feedwater systems. Understanding these flow types helps in selecting the appropriate pump based on performance requirements like flow rate, pressure, and application specifics.

What is Mixed Flow?

Mixed flow refers to a type of fluid movement combining both axial and radial directions, commonly found in pumps and fans. This flow pattern allows for higher pressure generation than axial flow alone while maintaining better efficiency than purely radial flow. Mixed flow designs optimize energy transfer, making them suitable for applications requiring moderate flow rates and pressure.

What is Radial Flow?

Radial flow refers to a fluid movement pattern where the flow enters or exits a system perpendicular to the axis, moving outward or inward in a radial direction from a central point. This flow type is commonly observed in centrifugal pumps, compressors, and turbines, where fluid is directed from the center to the edge or vice versa, enhancing pressure and velocity efficiently. Radial flow devices are often chosen for applications requiring high pressure rise and compact design, as they enable effective energy transfer through centrifugal force.

Design Differences: Mixed vs Radial

Mixed flow pumps combine axial and radial flow characteristics, allowing fluid to move partially along the pump shaft and partially outward, resulting in moderate head and flow rates with compact designs. Radial flow pumps direct fluid perpendicularly to the shaft, generating higher pressure heads ideal for applications requiring significant elevation increases and lower flow rates. Design differences include impeller geometry, where mixed flow impellers have semi-axial blades, while radial flow impellers feature fully radial vanes optimized for pressure generation.

Efficiency Comparison

Mixed flow pumps generally exhibit higher efficiency at varying flow rates due to their combined axial and radial flow characteristics, providing a balanced hydraulic performance. Radial flow pumps excel in high-pressure applications but often experience efficiency drops at off-design points because of their purely radial flow pattern. Efficiency comparisons typically show mixed flow pumps maintain a more consistent and higher efficiency across a broader operating range than radial flow pumps.

Applications in Industry

Mixed flow pumps are widely used in industries requiring high flow rates with moderate head, such as water treatment, irrigation, and HVAC systems, due to their efficiency in handling large volumes of fluid. Radial flow pumps excel in applications demanding high pressure at lower flow rates, including chemical processing, oil refining, and boiler feed operations. The choice between mixed flow and radial flow pumps depends on specific industry requirements for flow rate and pressure to optimize performance and energy consumption.

Advantages of Mixed Flow

Mixed flow pumps combine the axial and radial flow principles, offering higher efficiency at medium flow rates and moderate heads compared to purely radial flow pumps. They typically provide a more compact design with smoother operation and reduced noise levels, making them ideal for applications requiring variable flow and pressure. Mixed flow pumps also exhibit better performance adaptability in changing conditions, enhancing energy savings and operational flexibility.

Advantages of Radial Flow

Radial flow pumps offer superior efficiency in handling high-pressure applications due to their robust design and ability to maintain consistent flow rates under varying conditions. They excel in durability and lower maintenance costs compared to mixed flow pumps, making them ideal for industrial processes requiring reliable, long-term performance. Their simple construction and effective fluid dynamics reduce the risk of cavitation and operational failures, enhancing overall system stability.

Selection Criteria for Flow Types

Mixed flow pumps are selected for applications requiring moderate head and flow rates with improved efficiency over pure axial or radial designs, suitable for water supply and irrigation. Radial flow pumps excel in high head, low flow scenarios, commonly used in boiler feed, chemical processing, and high-pressure systems due to their ability to generate substantial pressure. Selection criteria prioritize flow rate, head requirements, efficiency curves, and system compatibility to ensure optimal performance and energy consumption.

Conclusion and Recommendations

Mixed flow pumps offer a balanced combination of axial and radial flow characteristics, providing moderate head and flow rates ideal for applications requiring versatility. Radial flow pumps deliver higher head at lower flow rates, making them suitable for high-pressure systems such as water supply and boiler feed. Select mixed flow pumps for moderate head with variable flow, while radial flow pumps excel in high-head, low-flow scenarios to maximize efficiency and performance.

Mixed flow Infographic

libterm.com

libterm.com