Surface contact plays a crucial role in determining friction, heat transfer, and wear between materials in mechanical systems. The quality and characteristics of surface contact influence efficiency and longevity, impacting everything from industrial machinery to everyday devices. Explore the rest of the article to understand how optimizing surface contact can enhance your equipment's performance.

Table of Comparison

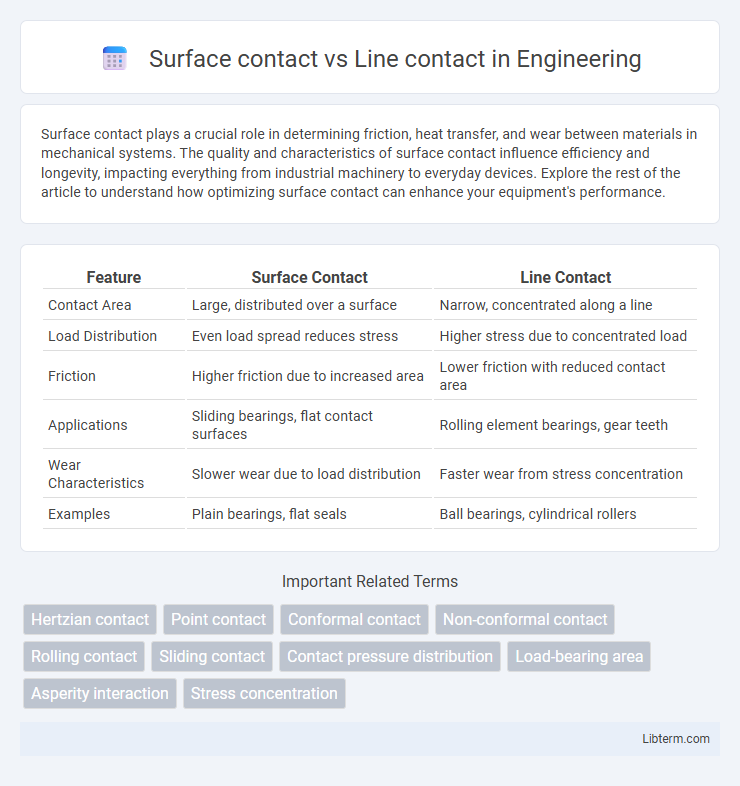

| Feature | Surface Contact | Line Contact |

|---|---|---|

| Contact Area | Large, distributed over a surface | Narrow, concentrated along a line |

| Load Distribution | Even load spread reduces stress | Higher stress due to concentrated load |

| Friction | Higher friction due to increased area | Lower friction with reduced contact area |

| Applications | Sliding bearings, flat contact surfaces | Rolling element bearings, gear teeth |

| Wear Characteristics | Slower wear due to load distribution | Faster wear from stress concentration |

| Examples | Plain bearings, flat seals | Ball bearings, cylindrical rollers |

Introduction to Surface and Line Contact

Surface contact involves the interaction between two contacting bodies over an area, distributing load and reducing stress concentrations, commonly seen in bearing surfaces and gear teeth. Line contact occurs when two bodies touch along a line, concentrating forces along that line, typical in cylindrical gears and roller bearings. Understanding the differences between surface and line contact is essential for optimizing stress distribution, wear resistance, and overall mechanical performance in engineering design.

Defining Surface Contact

Surface contact occurs when two solids touch across an area, distributing pressure evenly over the interface to reduce stress concentrations. This type of contact is common in applications like ball bearings and flat seals, where load distribution and wear resistance are critical. Surface contact enhances durability and performance by minimizing localized deformation compared to line contact, which involves contact along a narrow edge or line.

Understanding Line Contact

Line contact occurs when two curved surfaces meet along a single line rather than over an area, which significantly reduces the contact area compared to surface contact. This type of contact is common in rolling element bearings and gear tooth interfaces, where the load is distributed along the line, leading to higher contact stresses but improved precision and reduced friction. Understanding line contact is essential for optimizing mechanical design to enhance durability and performance under dynamic loads.

Key Differences Between Surface and Line Contact

Surface contact involves an area where two objects meet, distributing forces across a broad region, which reduces stress and wear, while line contact focuses stress along a narrow line, often leading to higher localized pressure. Bearings such as ball bearings typically utilize point or line contact for reduced friction and precise movement, whereas roller bearings rely on surface contact to support heavier loads. The choice between surface and line contact affects load capacity, friction characteristics, and durability in mechanical design.

Applications of Surface Contact

Surface contact provides greater load distribution and enhanced stability, making it ideal for applications requiring heavy load support such as plain bearings, thrust bearings, and machine slides. This type of contact reduces stress concentration and wear, extending the lifespan of components in automotive engines, industrial machinery, and aerospace assemblies. Surface contact is preferred in applications where smooth motion and vibration damping are critical for performance and reliability.

Applications of Line Contact

Line contact bearings are essential in applications requiring the support of heavy radial loads with minimal friction, such as in rolling element bearings like cylindrical roller bearings. These bearings efficiently handle high load capacities in machinery including conveyors, electric motors, and gearboxes, where precision and durability are critical. Their ability to maintain alignment under heavy radial stress makes them ideal for industrial and automotive applications demanding robust performance.

Advantages of Surface Contact

Surface contact provides a larger contact area between interacting components, which distributes loads more evenly and reduces localized stress concentrations that can cause premature wear or failure. This enhanced load distribution improves durability and reliability in mechanical systems such as gears, bearings, and seals. Higher frictional stability and better energy transfer efficiency are additional benefits, making surface contact ideal for applications requiring consistent performance under varying load conditions.

Benefits of Line Contact

Line contact offers enhanced load distribution by concentrating force along a narrow line, reducing stress and wear on contact surfaces compared to surface contact. This type of contact improves precision and operational efficiency in bearings and gear assemblies, enabling smoother motion and higher speed capabilities. The minimized friction and heat generation extend component lifespan, making line contact ideal for high-performance mechanical applications.

Common Materials for Each Contact Type

Surface contact typically involves materials like rubber, plastic, and soft metals such as aluminum or copper, which provide broad, distributed load-bearing areas ideal for cushioning and sealing applications. Line contact usually features harder materials like steel, cast iron, or ceramics, designed to withstand high stress along narrow contact lines seen in gears, bearings, and cam followers. Material selection depends on factors like load capacity, wear resistance, and frictional properties tailored to either surface or line contact mechanics.

Choosing the Right Contact Type for Your Needs

Surface contact offers greater load distribution and reduces stress concentrations, ideal for applications requiring high durability and stability under heavy loads. Line contact provides precise alignment and lower friction, making it suitable for high-speed or precision machinery where minimal contact area is beneficial. Selecting the right contact type depends on factors like load capacity, speed, and alignment requirements to optimize performance and component lifespan.

Surface contact Infographic

libterm.com

libterm.com