Material removal techniques are essential in manufacturing processes to shape, finish, or refine workpieces by eliminating excess material through methods such as machining, grinding, or chemical etching. These processes impact surface quality, dimensional accuracy, and production efficiency, making the selection of the appropriate removal method critical for your project's success. Explore the full article to understand the key methods and their applications in detail.

Table of Comparison

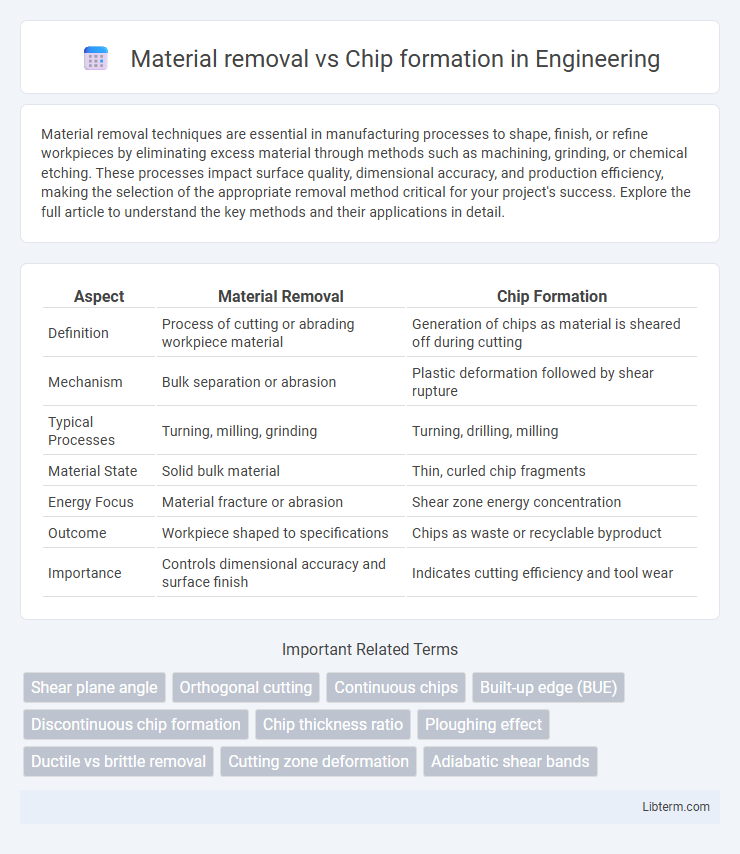

| Aspect | Material Removal | Chip Formation |

|---|---|---|

| Definition | Process of cutting or abrading workpiece material | Generation of chips as material is sheared off during cutting |

| Mechanism | Bulk separation or abrasion | Plastic deformation followed by shear rupture |

| Typical Processes | Turning, milling, grinding | Turning, drilling, milling |

| Material State | Solid bulk material | Thin, curled chip fragments |

| Energy Focus | Material fracture or abrasion | Shear zone energy concentration |

| Outcome | Workpiece shaped to specifications | Chips as waste or recyclable byproduct |

| Importance | Controls dimensional accuracy and surface finish | Indicates cutting efficiency and tool wear |

Introduction to Material Removal and Chip Formation

Material removal and chip formation are fundamental processes in manufacturing, especially in machining operations where material is selectively cut away from a workpiece. Material removal involves the detachment of material in the form of chips through mechanical action, typically by cutting tools with sharp edges that induce plastic deformation and fracture. Understanding chip formation mechanisms, including types such as continuous, discontinuous, and built-up edge chips, is essential for optimizing machining parameters, tool life, and surface finish quality.

Fundamentals of Material Removal Processes

Material removal involves the detachment of material from a workpiece through mechanical, thermal, or chemical means, crucial for shaping and finishing in manufacturing. Chip formation specifically refers to the process where a cutting tool shears material, producing chips that carry away excess substance, a fundamental aspect in machining operations. Understanding the mechanics of chip formation aids in optimizing tool geometry, cutting parameters, and surface integrity in material removal processes.

Chip Formation Mechanisms in Machining

Chip formation in machining occurs through material deformation mechanisms such as shearing, where the workpiece material flows along a shear plane causing chip separation. Different chip types, including continuous, built-up edge, and discontinuous chips, result from variations in cutting conditions, material properties, and tool geometry. Understanding these chip formation mechanisms is vital for optimizing cutting forces, surface finish, and tool life in manufacturing processes.

Factors Affecting Chip Formation

Chip formation during material removal is influenced by factors such as cutting speed, tool geometry, material properties, and feed rate. The hardness and ductility of the workpiece material determine the type of chip produced, whether continuous, segmented, or discontinuous. Optimal tool angle and cutting conditions minimize heat generation and improve chip flow, enhancing machining efficiency and surface finish.

Types of Chips Produced During Machining

Types of chips produced during machining vary according to cutting conditions and material properties, including continuous, discontinuous, and serrated chips. Continuous chips form under ductile materials with high cutting speed, producing smooth surfaces and improved tool life. Discontinuous chips occur in brittle materials or low cutting speeds, resulting in fragmented chips that can cause surface roughness and tool wear.

Role of Cutting Parameters in Material Removal

Cutting parameters such as cutting speed, feed rate, and depth of cut critically influence material removal by controlling the efficiency and quality of chip formation. Optimal cutting speed ensures appropriate thermal softening, reducing tool wear and improving surface finish, while feed rate dictates chip thickness and affects material flow behavior during deformation. Depth of cut determines the volume of material removed per pass, directly impacting cutting forces and energy consumption in machining processes.

Relationship Between Tool Geometry and Chip Formation

The relationship between tool geometry and chip formation is critical in material removal processes as specific tool angles and edge sharpness directly influence chip shape and size. Positive rake angles promote smoother chip flow and reduce cutting forces, enhancing surface finish and tool life, while negative rake angles result in thicker, curled chips and increased cutting resistance. Understanding this interplay enables optimization of tool design to achieve efficient material removal and improved machining performance.

Impact of Workpiece Material Properties on Chip Behavior

Workpiece material properties such as hardness, ductility, and grain structure significantly influence chip formation during machining processes. Harder materials typically produce discontinuous or segmented chips due to brittle fracture, while ductile materials tend to generate continuous, ribbon-like chips resulting from plastic deformation. Understanding these behaviors allows optimization of cutting parameters to enhance machining efficiency and surface finish.

Comparative Analysis: Material Removal vs. Chip Formation

Material removal involves the process of subtracting material from a workpiece, typically through cutting, grinding, or erosion, while chip formation specifically refers to the segmentation of material into discrete chips during machining operations like turning or milling. The efficiency of chip formation directly impacts surface finish and tool life, whereas overall material removal rates determine productivity and cost-effectiveness. Comparative analysis reveals that optimizing chip morphology and minimizing built-up edge formation are crucial for enhancing material removal performance and achieving precise dimensional tolerances.

Advances and Challenges in Machining Technology

Material removal in machining primarily involves processes like cutting, grinding, and milling, where material is physically separated from the workpiece, whereas chip formation refers to the deformation and detachment of material layers as chips during cutting. Advances in machining technology, such as high-speed machining, laser-assisted cutting, and cryogenic cooling, have enhanced chip formation control, improving surface quality and tool life while minimizing heat and deformation. Challenges persist in managing complex chip morphology, reducing tool wear, and optimizing cutting parameters for new materials, necessitating ongoing research into real-time monitoring and adaptive control systems.

Material removal Infographic

libterm.com

libterm.com