Knoop hardness is a microhardness testing method used to measure the hardness of very thin materials or small parts by applying a diamond-shaped indenter under a specific load. This technique provides precise hardness values important for assessing material properties such as thin coatings, ceramics, and metals. Explore the rest of the article to understand how Knoop hardness testing can benefit your material analysis needs.

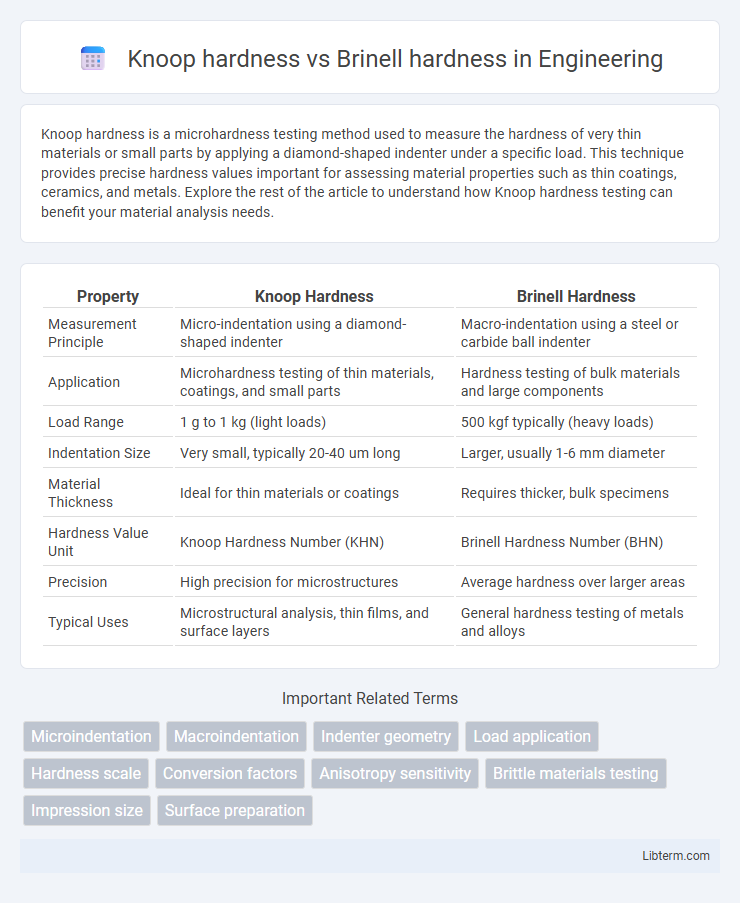

Table of Comparison

| Property | Knoop Hardness | Brinell Hardness |

|---|---|---|

| Measurement Principle | Micro-indentation using a diamond-shaped indenter | Macro-indentation using a steel or carbide ball indenter |

| Application | Microhardness testing of thin materials, coatings, and small parts | Hardness testing of bulk materials and large components |

| Load Range | 1 g to 1 kg (light loads) | 500 kgf typically (heavy loads) |

| Indentation Size | Very small, typically 20-40 um long | Larger, usually 1-6 mm diameter |

| Material Thickness | Ideal for thin materials or coatings | Requires thicker, bulk specimens |

| Hardness Value Unit | Knoop Hardness Number (KHN) | Brinell Hardness Number (BHN) |

| Precision | High precision for microstructures | Average hardness over larger areas |

| Typical Uses | Microstructural analysis, thin films, and surface layers | General hardness testing of metals and alloys |

Introduction to Hardness Testing Methods

Knoop hardness and Brinell hardness are two prominent methods used in hardness testing to evaluate a material's resistance to deformation. Knoop hardness testing employs a diamond indenter with an elongated pyramidal shape, producing a very shallow, micro-scale indentation ideal for thin materials and coatings. Brinell hardness testing uses a steel or carbide ball indenter to create larger indentations, suitable for bulk materials and offering a more averaged hardness value over a wider surface area.

Overview of Knoop Hardness Test

The Knoop hardness test utilizes a diamond indenter with an elongated pyramidal shape to measure hardness on a micro-scale, ideal for thin materials and small surface areas. It produces an indentation much smaller than the Brinell test, allowing precise evaluation of microhardness in coatings, thin films, and small components where Brinell's larger steel ball indenter would be impractical. This test is highly sensitive to surface conditions and is widely used in materials science for hardness mapping at a microscopic level.

Overview of Brinell Hardness Test

The Brinell hardness test measures the resistance of a material to indentation by pressing a hardened steel or carbide ball into the surface under a specified load. It is widely used for testing metals and alloys with coarse or uneven grain structures due to its large indentation size, which averages the hardness over a broader area. Compared to the Knoop hardness test, which is suitable for micro-hardness testing with a diamond indenter, the Brinell test provides a more general hardness value for bulk materials.

Principle of Measurement: Knoop vs Brinell

The Knoop hardness test measures microhardness by indenting a material's surface with a diamond-shaped indenter under a low load and calculating hardness from the diagonal length of the tiny indentation. The Brinell hardness test evaluates macrohardness by pressing a hardened steel or carbide ball into the material with a higher load, measuring the diameter of the resulting circular indentation to determine hardness. Knoop is ideal for thin materials and small, localized areas, while Brinell suits larger, more homogeneous specimens.

Indenter Materials and Shapes Comparison

Knoop hardness testing uses a diamond indenter with an elongated, pyramidal shape designed for testing very thin materials or small volumes, allowing precise measurement of hardness on microstructural features. Brinell hardness employs a spherical indenter typically made from hardened steel or tungsten carbide, suitable for testing bulk materials with an indentation diameter that provides an average hardness over a larger surface area. The choice between Knoop and Brinell indenters hinges on the scale and sensitivity required, with diamond Knoop indenters providing high-resolution hardness data on small or thin samples, while Brinell indenters offer robustness and suitability for coarse-grained or rough surfaces.

Load Application Differences

Knoop hardness testing uses a diamond indenter with an elongated, narrow shape to apply a very small, precise load, ideal for measuring thin materials or surface coatings. Brinell hardness testing employs a large steel or carbide ball indenter and applies a significantly higher load, distributing force over a larger area to assess bulk material hardness. The difference in load application results in Knoop being suitable for microhardness measurements, while Brinell is better for macroscopic, structural hardness evaluations.

Material Suitability for Each Test

Knoop hardness testing is ideal for thin materials, coatings, and small parts due to its micro-indentation and minimal material deformation, providing precise hardness values on microscopic scales. Brinell hardness testing suits bulk materials and castings with coarse structures, as it uses a larger indenter and generates average hardness over a wider surface area, effectively assessing heterogeneous or rough materials. Material selection between these tests depends on surface thickness, homogeneity, and the required resolution of hardness measurement.

Accuracy and Precision in Results

Knoop hardness testing offers higher accuracy and precision for microhardness measurements due to its smaller, elongated indentation, which allows for detailed analysis of thin materials and surface coatings. Brinell hardness testing produces larger, round indentations suitable for bulk material characterization but may yield less precise results on heterogeneous or small samples. The choice between Knoop and Brinell hardness tests depends on the required resolution and material type, with Knoop preferred for fine-scale, precise data and Brinell for broader, more general assessments.

Applications in Industry and Research

Knoop hardness testing is preferred in microelectronics and thin films due to its ability to measure very small and localized areas with minimal sample deformation, making it ideal for delicate or heterogeneous materials. Brinell hardness testing is widely used in heavy industry and metallurgy to assess bulk materials and large components like castings and forgings, providing reliable measurements of overall material resistance to indentation. Research applications leverage Knoop tests for detailed surface characterization, while Brinell tests support quality control in manufacturing environments requiring standardized hardness values.

Choosing Between Knoop and Brinell Hardness Methods

When choosing between Knoop and Brinell hardness methods, consider the material type and test scale; Knoop hardness is ideal for thin materials, coatings, and micro-scale testing due to its minimal indentation size, while Brinell hardness suits bulk materials with coarse microstructures requiring larger indentation measurements. Knoop testing provides high precision on small, delicate samples without causing significant damage, making it preferred in microelectronics and thin film analysis. Brinell hardness testing, using larger steel or carbide balls, effectively assesses overall material robustness in metals and alloys with heterogeneous structures.

Knoop hardness Infographic

libterm.com

libterm.com