Predictive maintenance leverages real-time data and advanced analytics to predict equipment failures before they occur, reducing downtime and maintenance costs. By monitoring machine conditions, it enables timely interventions that enhance operational efficiency and extend asset lifespan. Discover how implementing predictive maintenance can transform Your maintenance strategy and boost productivity in the rest of this article.

Table of Comparison

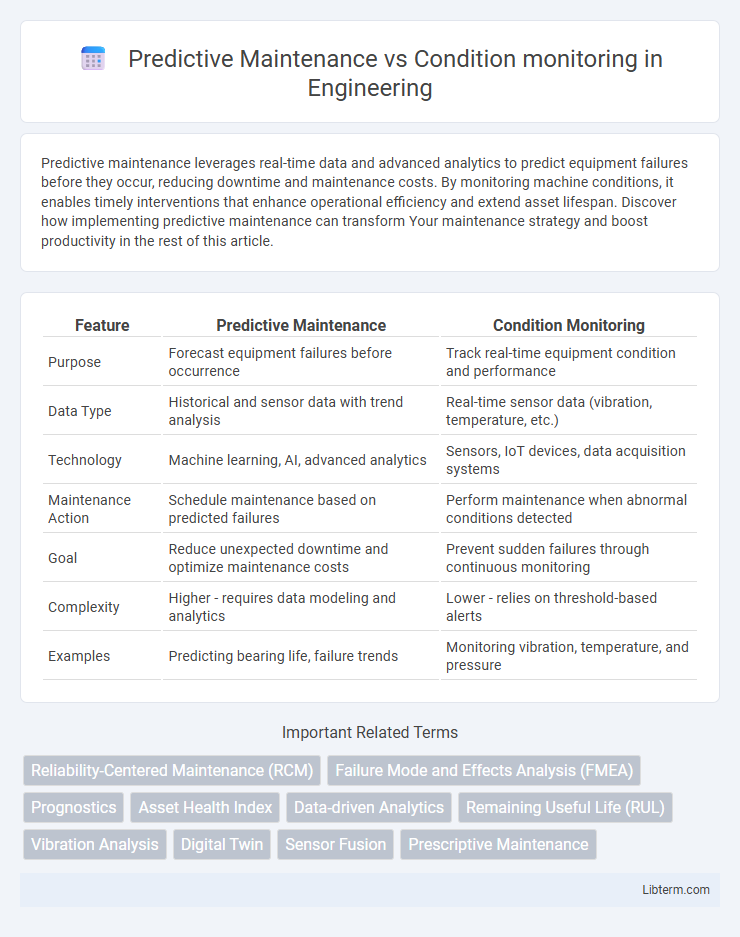

| Feature | Predictive Maintenance | Condition Monitoring |

|---|---|---|

| Purpose | Forecast equipment failures before occurrence | Track real-time equipment condition and performance |

| Data Type | Historical and sensor data with trend analysis | Real-time sensor data (vibration, temperature, etc.) |

| Technology | Machine learning, AI, advanced analytics | Sensors, IoT devices, data acquisition systems |

| Maintenance Action | Schedule maintenance based on predicted failures | Perform maintenance when abnormal conditions detected |

| Goal | Reduce unexpected downtime and optimize maintenance costs | Prevent sudden failures through continuous monitoring |

| Complexity | Higher - requires data modeling and analytics | Lower - relies on threshold-based alerts |

| Examples | Predicting bearing life, failure trends | Monitoring vibration, temperature, and pressure |

Introduction to Predictive Maintenance and Condition Monitoring

Predictive maintenance utilizes advanced data analytics and machine learning to forecast equipment failures before they occur, optimizing maintenance schedules and reducing downtime. Condition monitoring involves continuous or periodic measurement of equipment parameters such as vibration, temperature, and pressure to detect deviations from normal operation. Both methods aim to improve asset reliability, but predictive maintenance leverages historical and real-time data for proactive decision-making, while condition monitoring focuses on real-time status assessment and early anomaly detection.

Defining Predictive Maintenance

Predictive maintenance is a proactive maintenance strategy that uses data analysis, machine learning, and sensor inputs to predict equipment failures before they occur, optimizing maintenance schedules and reducing downtime. Unlike condition monitoring, which primarily tracks the real-time health of assets, predictive maintenance leverages historical and real-time data to forecast future equipment performance and potential issues. This approach minimizes unexpected breakdowns by enabling timely interventions based on predictive insights derived from vibration analysis, temperature monitoring, and operational data trends.

Understanding Condition Monitoring

Condition monitoring involves continuously tracking the real-time health and performance of equipment using sensors and diagnostic tools to detect early signs of wear or failure. It provides critical data on vibration, temperature, pressure, and other operational parameters, enabling timely maintenance interventions before breakdowns occur. This approach reduces unexpected downtime by identifying anomalies and trends, enhancing asset reliability and extending machinery lifespan.

Key Differences Between Predictive Maintenance and Condition Monitoring

Predictive maintenance uses data analytics and machine learning to forecast equipment failures before they occur, enabling scheduled repairs and minimizing downtime. Condition monitoring continuously measures real-time equipment parameters like vibration, temperature, and pressure to detect abnormalities as they happen. While condition monitoring provides immediate status updates, predictive maintenance leverages historical and real-time data to predict future maintenance needs, optimizing resource allocation and extending asset lifespan.

Technologies Used in Predictive Maintenance

Predictive maintenance leverages advanced technologies such as machine learning algorithms, IoT sensors, and real-time data analytics to predict equipment failures before they occur, improving operational efficiency and reducing downtime. Condition monitoring primarily relies on vibration analysis, thermal imaging, and ultrasonic testing to assess asset health but lacks the predictive insights provided by AI-driven data interpretation. Key technologies in predictive maintenance include cloud computing for scalable data storage, edge computing for immediate data processing, and digital twins to simulate and forecast machine behavior under varying conditions.

Technologies Used in Condition Monitoring

Condition monitoring employs advanced technologies such as vibration analysis, ultrasonic testing, infrared thermography, and oil analysis to continuously assess equipment health and detect early signs of failure. These sensor-based techniques provide real-time data on machine conditions, enabling timely interventions before breakdowns occur. Unlike predictive maintenance, which relies on historical data and algorithms for future failure predictions, condition monitoring focuses on immediate, accurate diagnostics to maintain operational efficiency.

Benefits of Predictive Maintenance

Predictive maintenance uses advanced analytics and IoT sensor data to forecast equipment failures before they occur, reducing unplanned downtime and lowering repair costs significantly. This proactive approach extends asset lifespan by enabling timely interventions tailored to actual equipment conditions. Compared to condition monitoring that mainly detects current performance issues, predictive maintenance optimizes maintenance scheduling and resource allocation, leading to improved operational efficiency and higher return on investment.

Advantages of Condition Monitoring

Condition monitoring offers real-time insights into equipment health by continuously tracking parameters like vibration, temperature, and pressure, enabling early detection of anomalies before failures occur. This proactive approach reduces unplanned downtime, lowers maintenance costs, and extends machinery lifespan by facilitating timely interventions based on actual condition rather than predetermined schedules. Compared to predictive maintenance, condition monitoring provides more immediate and precise data, enhancing operational efficiency and asset reliability across industries such as manufacturing, energy, and transportation.

Industry Applications and Use Cases

Predictive maintenance leverages advanced data analytics and machine learning to forecast equipment failures, enabling industries such as manufacturing, energy, and transportation to optimize maintenance schedules and reduce unplanned downtime. Condition monitoring involves real-time tracking of machinery health through sensors measuring vibration, temperature, and pressure, commonly applied in sectors like aerospace and oil and gas to detect anomalies early. Combining both approaches enhances asset reliability, improves safety, and extends the lifespan of critical industrial equipment.

Choosing the Right Maintenance Strategy

Predictive maintenance leverages real-time data analytics and machine learning algorithms to forecast equipment failures before they occur, minimizing downtime and optimizing resource allocation. Condition monitoring involves continuous or periodic measurement of specific parameters like vibration, temperature, and pressure to detect early signs of deterioration. Choosing the right maintenance strategy depends on asset criticality, operational costs, and available technology, with predictive maintenance favored for high-value, complex machinery and condition monitoring suited for less critical or simpler equipment.

Predictive Maintenance Infographic

libterm.com

libterm.com