Ferritic steels exhibit excellent corrosion resistance and high thermal conductivity, making them ideal for automotive and industrial applications. Their magnetic properties and low carbon content enhance durability and weldability, providing long-term performance benefits. Discover how ferritic steels can improve your projects by reading the rest of this article.

Table of Comparison

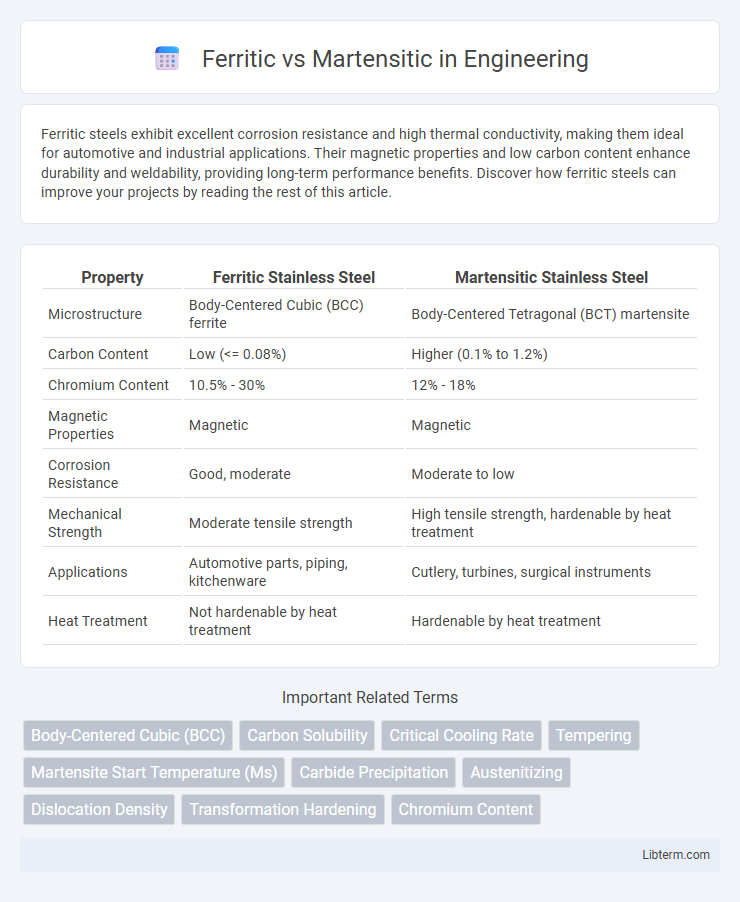

| Property | Ferritic Stainless Steel | Martensitic Stainless Steel |

|---|---|---|

| Microstructure | Body-Centered Cubic (BCC) ferrite | Body-Centered Tetragonal (BCT) martensite |

| Carbon Content | Low (<= 0.08%) | Higher (0.1% to 1.2%) |

| Chromium Content | 10.5% - 30% | 12% - 18% |

| Magnetic Properties | Magnetic | Magnetic |

| Corrosion Resistance | Good, moderate | Moderate to low |

| Mechanical Strength | Moderate tensile strength | High tensile strength, hardenable by heat treatment |

| Applications | Automotive parts, piping, kitchenware | Cutlery, turbines, surgical instruments |

| Heat Treatment | Not hardenable by heat treatment | Hardenable by heat treatment |

Introduction to Ferritic and Martensitic Stainless Steels

Ferritic stainless steels contain 10.5% to 30% chromium with low carbon content, offering excellent corrosion resistance and good formability while maintaining magnetic properties. Martensitic stainless steels have higher carbon content, enabling heat treatment for superior hardness and strength, commonly used in cutting tools and wear-resistant applications. Both types differ significantly in microstructure, mechanical properties, and corrosion resistance, influencing their selection for automotive, industrial, and kitchenware applications.

Chemical Composition Differences

Ferritic steels primarily contain 10-30% chromium with low carbon content, typically less than 0.1%, which enhances corrosion resistance and maintains a body-centered cubic (BCC) structure. Martensitic steels possess higher carbon content, ranging from 0.1% to 1.2%, alongside 11-17% chromium, enabling hardening through heat treatment and forming a body-centered tetragonal (BCT) structure. The increased carbon in martensitic steels results in greater strength and hardness, whereas ferritic steels emphasize toughness and ductility due to their lower carbon levels.

Microstructural Characteristics

Ferritic steels exhibit a body-centered cubic (BCC) microstructure characterized by relatively low carbon content, resulting in good ductility and resistance to oxidation. Martensitic steels, on the other hand, possess a highly distorted body-centered tetragonal (BCT) microstructure formed by rapid quenching, which increases hardness and tensile strength but reduces toughness. The microstructural differences between ferritic and martensitic steels critically influence their mechanical properties and applications in high-temperature and wear-resistant environments.

Mechanical Properties Comparison

Ferritic steels exhibit lower tensile strength but higher ductility and corrosion resistance compared to martensitic steels, which offer superior hardness and tensile strength due to their body-centered tetragonal (BCT) crystal structure formed during rapid cooling. Martensitic steels typically have higher yield strength and wear resistance, making them ideal for applications requiring toughness and durability, whereas ferritic steels provide better thermal conductivity and resistance to stress corrosion cracking. The choice between ferritic and martensitic steels depends on balancing mechanical properties like hardness, toughness, and ductility for specific engineering applications.

Corrosion Resistance: Ferritic vs Martensitic

Ferritic stainless steels exhibit superior corrosion resistance in oxidizing and mildly corrosive environments due to their high chromium content and absence of nickel, making them ideal for automotive exhaust systems and industrial applications. Martensitic stainless steels, containing higher carbon levels for increased hardness, offer moderate corrosion resistance but are more susceptible to pitting and stress corrosion cracking, limiting their effectiveness in highly corrosive environments. Optimal corrosion resistance in ferritic steels results from their stable body-centered cubic (BCC) structure, whereas martensitic steels require careful heat treatment to balance strength and corrosion performance.

Heat Treatment Effects

Heat treatment of ferritic steels enhances ductility and corrosion resistance by promoting grain growth and stress relief without significant phase transformation. Martensitic steels undergo quenching and tempering to achieve high hardness and strength through the formation of a supersaturated solid solution and tempered martensite structures. The differential response in heat treatment between ferritic and martensitic steels is critical for tailoring mechanical properties for applications requiring either toughness or wear resistance.

Common Applications and Industries

Ferritic stainless steels, known for their excellent corrosion resistance and ductility, are commonly used in automotive components, kitchen appliances, and architectural applications. Martensitic stainless steels provide high strength and hardness, making them ideal for cutlery, surgical instruments, and industrial valves. Both steel types find extensive applications in the chemical, food processing, and petrochemical industries due to their specific mechanical properties and resistance to corrosion.

Weldability and Fabrication Considerations

Ferritic stainless steels exhibit better weldability than martensitic grades due to their lower carbon content, reducing the risk of cracking and distortion during fabrication. Martensitic steels require preheating and post-weld heat treatment to avoid hardness-induced brittleness and maintain mechanical properties, complicating the welding process. The fabrication of ferritic steels is generally easier, while martensitic alloys demand careful control of welding parameters and thermal cycles to ensure structural integrity.

Cost Analysis and Availability

Ferritic steels generally offer lower production costs due to simpler alloy compositions and manufacturing processes compared to martensitic steels, which require more complex heat treatments elevating their cost. Ferritic grades are more widely available and commonly produced, benefiting from established supply chains and economies of scale, whereas martensitic steels often have limited availability due to specialized applications. Cost analysis reveals ferritic steels as cost-effective options for high-volume, less demanding environments, while martensitic steels command premium pricing justified by superior strength and hardness for critical uses.

Selecting the Right Stainless Steel for Your Needs

Ferritic stainless steel offers excellent corrosion resistance and magnetic properties, making it ideal for automotive and industrial applications where durability and moderate strength are required. Martensitic stainless steel provides superior hardness and wear resistance due to its higher carbon content, suitable for cutting tools, surgical instruments, and structural components demanding toughness. Selecting the right stainless steel involves evaluating the specific mechanical properties, corrosion resistance level, and application environment to balance performance and cost effectively.

Ferritic Infographic

libterm.com

libterm.com