Visual inspection is a crucial process that involves examining objects, structures, or systems to detect surface defects, damages, or irregularities without causing harm. This method is widely used in quality control, maintenance, and safety assessments to ensure reliability and performance. Discover how mastering visual inspection techniques can enhance your ability to identify issues early by reading the rest of the article.

Table of Comparison

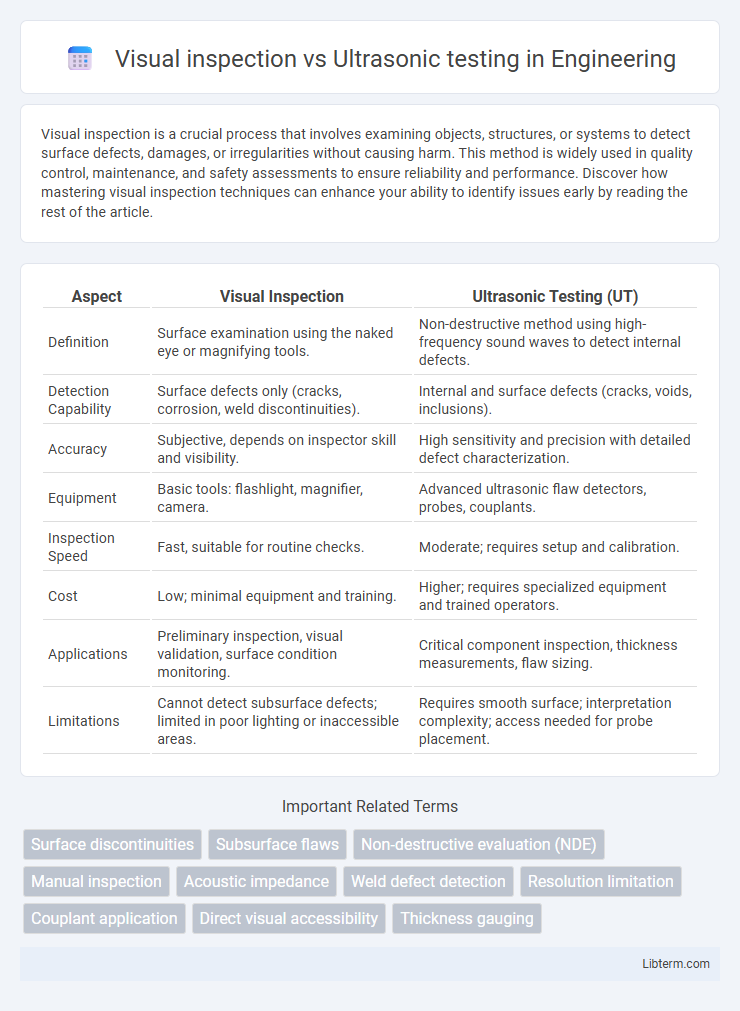

| Aspect | Visual Inspection | Ultrasonic Testing (UT) |

|---|---|---|

| Definition | Surface examination using the naked eye or magnifying tools. | Non-destructive method using high-frequency sound waves to detect internal defects. |

| Detection Capability | Surface defects only (cracks, corrosion, weld discontinuities). | Internal and surface defects (cracks, voids, inclusions). |

| Accuracy | Subjective, depends on inspector skill and visibility. | High sensitivity and precision with detailed defect characterization. |

| Equipment | Basic tools: flashlight, magnifier, camera. | Advanced ultrasonic flaw detectors, probes, couplants. |

| Inspection Speed | Fast, suitable for routine checks. | Moderate; requires setup and calibration. |

| Cost | Low; minimal equipment and training. | Higher; requires specialized equipment and trained operators. |

| Applications | Preliminary inspection, visual validation, surface condition monitoring. | Critical component inspection, thickness measurements, flaw sizing. |

| Limitations | Cannot detect subsurface defects; limited in poor lighting or inaccessible areas. | Requires smooth surface; interpretation complexity; access needed for probe placement. |

Introduction to Non-Destructive Testing Methods

Visual inspection is the most basic and widely used non-destructive testing (NDT) method, relying on the operator's ability to detect surface defects with the naked eye or optical aids. Ultrasonic testing (UT) utilizes high-frequency sound waves to detect internal flaws and measure material thickness, providing precise subsurface information unavailable through visual methods. Both methods are essential in ensuring structural integrity and safety without damaging the test materials, forming the foundation of modern NDT practices.

Understanding Visual Inspection: Basics and Applications

Visual inspection involves the direct examination of surfaces using the human eye or basic tools like magnifying glasses to identify defects such as cracks, corrosion, and misalignments in materials and structures. It is widely used across industries including manufacturing, construction, and aerospace for its simplicity, cost-effectiveness, and ability to provide immediate feedback during routine maintenance and quality control processes. Unlike ultrasonic testing, which uses high-frequency sound waves for subsurface defect detection, visual inspection is limited to surface-level assessment but remains essential for preliminary evaluations and quick assessments in various applications.

What is Ultrasonic Testing? Principles and Techniques

Ultrasonic Testing (UT) is a non-destructive testing method that uses high-frequency sound waves to detect internal flaws or characterize materials. The principles involve transmitting ultrasonic pulses into a material and analyzing the reflected signals from internal structures or defects to measure thickness or locate discontinuities. Techniques include pulse-echo, where the probe acts as both sender and receiver, and through-transmission, utilizing separate transmitting and receiving probes, enabling precise evaluation of welds, composites, and metal components beyond the surface-level detection achievable by Visual Inspection.

Key Differences Between Visual Inspection and Ultrasonic Testing

Visual inspection relies on the examiner's sight to detect surface defects and irregularities, making it ideal for identifying visible cracks, corrosion, or misalignments. Ultrasonic testing employs high-frequency sound waves to penetrate materials and uncover internal flaws, offering precise measurements of thickness and subsurface discontinuities. The key difference lies in visual inspection's limitation to surface-level evaluation, whereas ultrasonic testing enables comprehensive internal assessment without damaging the tested object.

Advantages of Visual Inspection in Industry

Visual inspection offers immediate and cost-effective detection of surface defects, reducing downtime in industrial maintenance. It requires minimal equipment and can be performed by trained personnel without specialized certifications, enhancing operational flexibility. This method provides real-time assessment, enabling quick decision-making and early identification of corrosion, cracks, or misalignments before defects worsen.

Benefits of Ultrasonic Testing for Flaw Detection

Ultrasonic testing offers superior flaw detection by using high-frequency sound waves to identify internal defects that visual inspection cannot detect. It provides precise measurements of crack depth, corrosion, and material thickness, enhancing maintenance accuracy and safety. This non-destructive method ensures early detection of hidden flaws, reducing the risk of unexpected failures and costly downtime.

Limitations of Visual Inspection vs Ultrasonic Testing

Visual inspection is limited by surface accessibility and cannot detect subsurface defects, relying heavily on the inspector's experience and lighting conditions. Ultrasonic testing overcomes these limitations by using high-frequency sound waves to detect internal flaws, providing precise depth and size measurements of defects. However, ultrasonic testing requires skilled operators and may be affected by material properties and complex geometries.

When to Choose Visual Inspection Over Ultrasonic Testing

Visual inspection is ideal for detecting surface defects, corrosion, and material discontinuities in accessible areas where quick and cost-effective evaluation is required. When the inspection involves simple geometry, visible flaws, or requires immediate assessment without specialized equipment, visual inspection provides rapid results. Ultrasonic testing is preferable for detecting internal flaws or thickness measurements but is unnecessary when surface conditions are clear and surface-breaking defects are the primary concern.

Cost, Accuracy, and Efficiency Comparison

Visual inspection offers a low-cost solution with moderate accuracy, ideal for surface defect detection but limited in identifying subsurface flaws. Ultrasonic testing, although more expensive due to specialized equipment and training, provides high accuracy and efficiency in detecting internal defects and thickness measurements. Selecting between these methods depends on budget constraints, required detection depth, and the criticality of defect identification in the inspection process.

Conclusion: Selecting the Right Inspection Method

Choosing between visual inspection and ultrasonic testing depends on factors such as defect type, material thickness, and inspection environment. Visual inspection suits surface-level flaws and quick assessments, while ultrasonic testing excels in detecting internal imperfections in thicker materials. Optimizing inspection accuracy and cost-efficiency requires balancing these strengths against project-specific requirements.

Visual inspection Infographic

libterm.com

libterm.com