Brittleness refers to a material's tendency to fracture or break without significant deformation when subjected to stress. Understanding the causes and consequences of brittleness is essential for selecting appropriate materials in engineering and manufacturing applications. Explore the rest of the article to learn how brittleness impacts material performance and how to prevent failure in your projects.

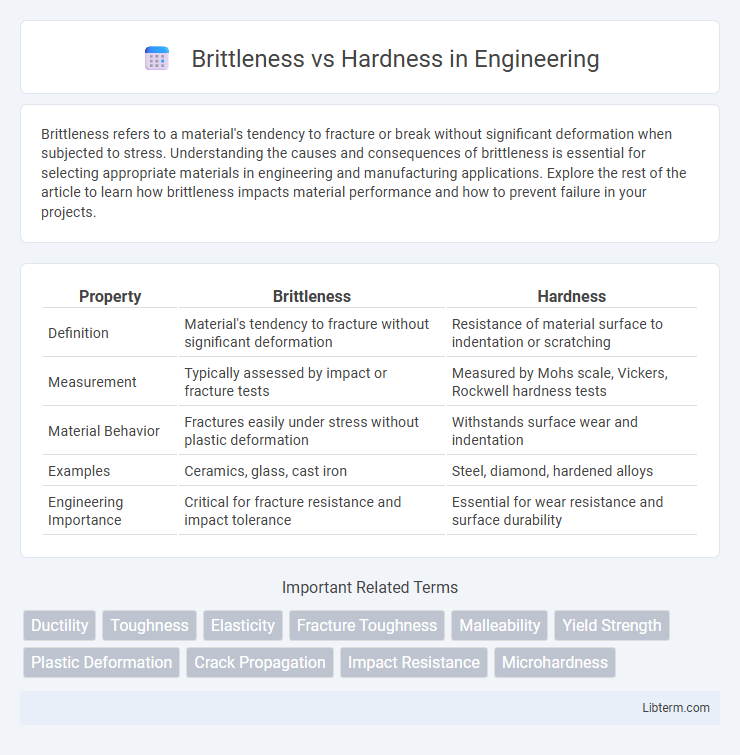

Table of Comparison

| Property | Brittleness | Hardness |

|---|---|---|

| Definition | Material's tendency to fracture without significant deformation | Resistance of material surface to indentation or scratching |

| Measurement | Typically assessed by impact or fracture tests | Measured by Mohs scale, Vickers, Rockwell hardness tests |

| Material Behavior | Fractures easily under stress without plastic deformation | Withstands surface wear and indentation |

| Examples | Ceramics, glass, cast iron | Steel, diamond, hardened alloys |

| Engineering Importance | Critical for fracture resistance and impact tolerance | Essential for wear resistance and surface durability |

Understanding Brittleness and Hardness

Brittleness refers to a material's tendency to fracture or break without significant deformation when subjected to stress, indicating low ductility. Hardness measures a material's resistance to surface indentation or scratching, revealing its ability to withstand localized plastic deformation. Understanding brittleness and hardness is essential for selecting materials that balance strength and toughness in engineering applications.

Defining Brittleness: Key Characteristics

Brittleness is characterized by a material's tendency to fracture or break without significant deformation when subjected to stress. Unlike hardness, which measures resistance to surface indentation or scratching, brittleness indicates low ductility and poor ability to absorb energy before failure. Commonly found in ceramics and glass, brittle materials fail abruptly under tensile or impact loading.

Defining Hardness: Essential Properties

Hardness measures a material's resistance to deformation, particularly surface scratching, indentation, or abrasion, and is a critical property in materials science for evaluating durability. It depends on atomic bonding strength and microstructure, influencing wear resistance and suitability for cutting tools or protective coatings. Unlike brittleness, which indicates a material's tendency to fracture without significant deformation, hardness reflects the ability to withstand external mechanical forces without surface damage.

Brittleness vs Hardness: Fundamental Differences

Brittleness and hardness are fundamental material properties that define different mechanical behaviors under stress. Brittleness refers to a material's tendency to fracture or break without significant deformation, whereas hardness measures a material's resistance to surface indentation or scratching. Understanding the difference is crucial in applications like construction or manufacturing, where brittleness indicates susceptibility to cracking, and hardness relates to wear resistance.

Factors Affecting Brittleness in Materials

Brittleness in materials is primarily influenced by factors such as temperature, strain rate, and microstructure, which dictate a material's ability to deform before fracturing. Low temperatures often increase brittleness by restricting atomic movement, while high strain rates reduce time for plastic deformation, leading to abrupt failure. The presence of impurities, grain size, and phase composition within the microstructure also critically affect brittleness by altering dislocation motion and crack propagation pathways.

Factors Influencing Material Hardness

Material hardness is influenced by factors such as atomic structure, bonding type, and microstructure. Elements with strong covalent or ionic bonds, like ceramics, tend to exhibit higher hardness due to resistance to deformation. Grain size and alloying elements also play crucial roles, as finer grains and certain alloying additions can enhance hardness by impeding dislocation movement.

Real-World Examples of Brittle Materials

Glass, ceramics, and cast iron exemplify brittle materials that fracture easily under stress without significant deformation. Unlike metals such as steel or aluminum, which combine hardness with ductility, brittle materials absorb minimal energy before breaking, making them prone to sudden failure in construction and manufacturing. The brittleness of these materials necessitates careful design considerations to prevent catastrophic structural damage.

Common Applications of Hard Materials

Hard materials are widely used in cutting tools, abrasives, and wear-resistant surfaces due to their ability to withstand deformation and maintain sharp edges. In industrial applications, materials like tungsten carbide and diamond are essential for machining, drilling, and grinding processes where durability and precision are critical. Their high hardness ensures longevity and efficiency in conditions involving heavy mechanical stress and friction.

Testing Methods for Brittleness and Hardness

Brittleness testing often involves impact tests like the Charpy or Izod test, measuring a material's ability to absorb energy before fracturing. Hardness testing methods include the Rockwell, Brinell, and Vickers tests, which quantify resistance to indentation under a specific load. Both testing techniques provide critical data for assessing material performance in mechanical engineering and quality control contexts.

Importance of Distinguishing Brittleness from Hardness

Understanding the difference between brittleness and hardness is crucial for selecting materials in engineering and manufacturing applications to prevent unexpected failures. Brittleness measures a material's tendency to fracture under stress without significant deformation, while hardness indicates resistance to surface indentation or scratching. Distinguishing these properties ensures appropriate material choice to balance durability and resilience, reducing the risk of catastrophic breakage or excessive wear.

Brittleness Infographic

libterm.com

libterm.com