Laser beam welding offers precise, high-speed joining of metals with minimal distortion and excellent weld quality. Its focused energy source enables deep penetration, making it ideal for automotive, aerospace, and electronics industries. Discover how this advanced technique can enhance Your manufacturing processes by reading the full article.

Table of Comparison

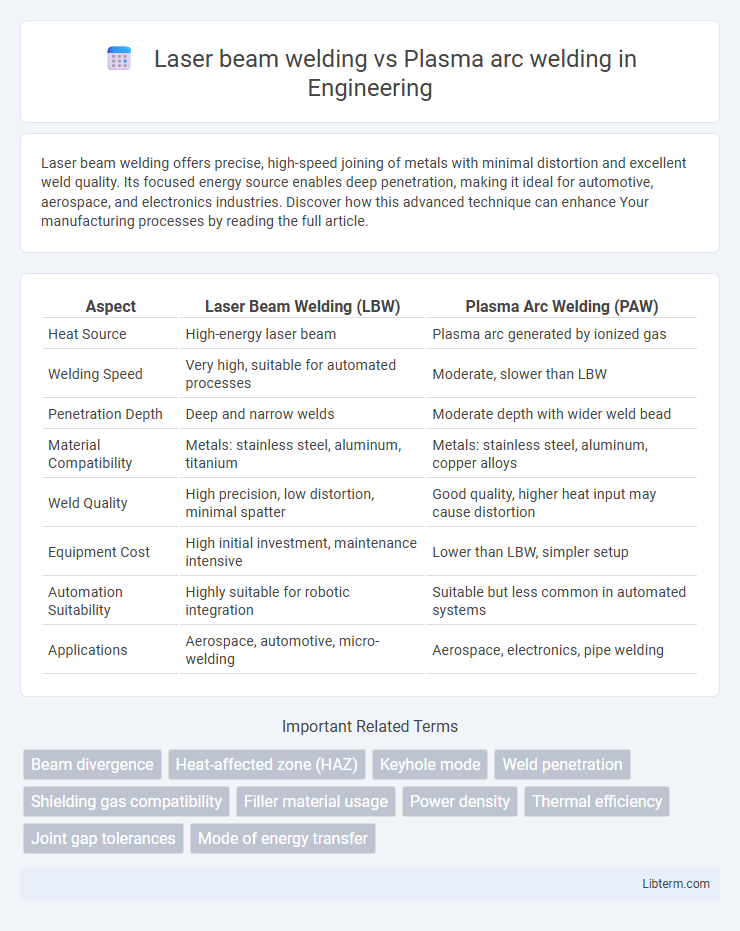

| Aspect | Laser Beam Welding (LBW) | Plasma Arc Welding (PAW) |

|---|---|---|

| Heat Source | High-energy laser beam | Plasma arc generated by ionized gas |

| Welding Speed | Very high, suitable for automated processes | Moderate, slower than LBW |

| Penetration Depth | Deep and narrow welds | Moderate depth with wider weld bead |

| Material Compatibility | Metals: stainless steel, aluminum, titanium | Metals: stainless steel, aluminum, copper alloys |

| Weld Quality | High precision, low distortion, minimal spatter | Good quality, higher heat input may cause distortion |

| Equipment Cost | High initial investment, maintenance intensive | Lower than LBW, simpler setup |

| Automation Suitability | Highly suitable for robotic integration | Suitable but less common in automated systems |

| Applications | Aerospace, automotive, micro-welding | Aerospace, electronics, pipe welding |

Introduction to Laser Beam Welding and Plasma Arc Welding

Laser Beam Welding (LBW) utilizes a high-intensity laser to produce a concentrated heat source, enabling deep and precise welds with minimal distortion, making it ideal for thin materials and complex geometries. Plasma Arc Welding (PAW) employs a plasma torch that generates a high-temperature ionized gas, offering greater arc stability and control over weld penetration for thicker materials. Both technologies provide advantages in industrial manufacturing, with LBW excelling in speed and precision, while PAW delivers robust welds in demanding applications.

Fundamental Principles of Each Welding Method

Laser beam welding utilizes a concentrated laser light source to melt and fuse materials with high precision and minimal thermal distortion, enabling deep penetration and narrow welds. Plasma arc welding employs an ionized gas plasma jet to generate an intense heat source, allowing for effective welds on thick materials and producing strong, consistent joints. Both methods rely on controlled heat input but differ in energy delivery mechanisms and applications based on material thickness and welding speed requirements.

Equipment and Setup Requirements

Laser beam welding requires high-precision lasers and complex optical systems for focusing the beam, demanding meticulously aligned and clean environments to ensure optimal performance. Plasma arc welding equipment involves a plasma torch and a more robust power supply capable of generating and maintaining the plasma arc, typically necessitating less stringent alignment but larger, more durable hardware. Both techniques require specialized safety measures, but laser beam welding setups often include advanced enclosure and ventilation systems to handle laser radiation and fumes.

Process Efficiency and Speed Comparison

Laser beam welding delivers higher process efficiency and faster welding speeds due to its concentrated energy density, enabling deep penetration with minimal heat input and reduced distortion. Plasma arc welding offers moderate speed but generally lower efficiency, as its broader heat source causes more extensive thermal impact and slower cooling rates. Laser welding is particularly advantageous in applications requiring precision and rapid throughput, outperforming plasma arc welding in speed and energy utilization metrics.

Material Compatibility and Thickness Range

Laser beam welding offers superior precision and control, making it ideal for joining thin materials such as stainless steel, aluminum, and titanium with thicknesses typically up to 5 mm. Plasma arc welding accommodates a wider range of materials, including carbon steel, stainless steel, and nickel alloys, and is effective for thicker sections ranging from 1 mm to over 25 mm. Material compatibility in laser welding is enhanced by focused energy input, whereas plasma arc welding benefits from a higher heat input suitable for thicker, more conductive metals.

Weld Quality and Precision Differences

Laser beam welding offers superior weld quality with minimal heat distortion and a narrow, deep penetration profile, making it ideal for precision applications requiring fine control. Plasma arc welding provides good weld quality but typically produces wider heat-affected zones and less precise control over weld bead dimensions compared to laser welding. The focused energy input of laser welding results in cleaner, stronger seams with reduced spatter, enhancing joint integrity in high-precision industries such as aerospace and medical device manufacturing.

Applications in Various Industries

Laser beam welding excels in precision applications across the aerospace, automotive, and electronics industries, where minimal heat distortion and high-speed welding of thin materials are critical. Plasma arc welding is favored in heavy-duty manufacturing sectors such as shipbuilding, pipeline construction, and stainless steel fabrication due to its deep penetration and ability to weld thicker sections efficiently. Both technologies support specialized industrial needs but differ fundamentally in heat source control, affecting their suitability for specific metal types and thicknesses.

Cost Considerations and Operational Expenses

Laser beam welding typically involves higher initial equipment costs but offers lower operational expenses due to faster processing speeds and minimal material wastage. Plasma arc welding requires less investment upfront but can incur higher ongoing costs from slower welding rates and increased consumable usage. Evaluating total cost of ownership, including maintenance and energy consumption, is essential for selecting the most cost-effective welding technology.

Safety Measures and Potential Hazards

Laser beam welding involves high-intensity laser light that requires strict eye protection and controlled environments to prevent burns and exposure to harmful radiation. Plasma arc welding emits intense ultraviolet radiation, harmful fumes, and hot metal splatter, necessitating ventilation systems and protective gear to avoid respiratory and skin injuries. Both methods demand rigorous safety protocols to minimize risks associated with high temperatures, electrical hazards, and exposure to hazardous fumes and radiation.

Choosing the Right Welding Process for Your Project

Laser beam welding offers high precision and minimal heat distortion, making it ideal for delicate, thin materials and intricate designs. Plasma arc welding provides deeper penetration and excels in thicker materials and high-production environments, delivering robust and consistent welds. Evaluate material thickness, joint design, production speed, and cost efficiency to choose the welding process best suited to your project's requirements.

Laser beam welding Infographic

libterm.com

libterm.com