Effective fastening techniques ensure strong, durable, and reliable connections across various materials and applications. Choosing the right fastener depends on factors like load requirements, environmental conditions, and material compatibility. Explore the rest of the article to discover expert tips and innovative fastening solutions tailored for your projects.

Table of Comparison

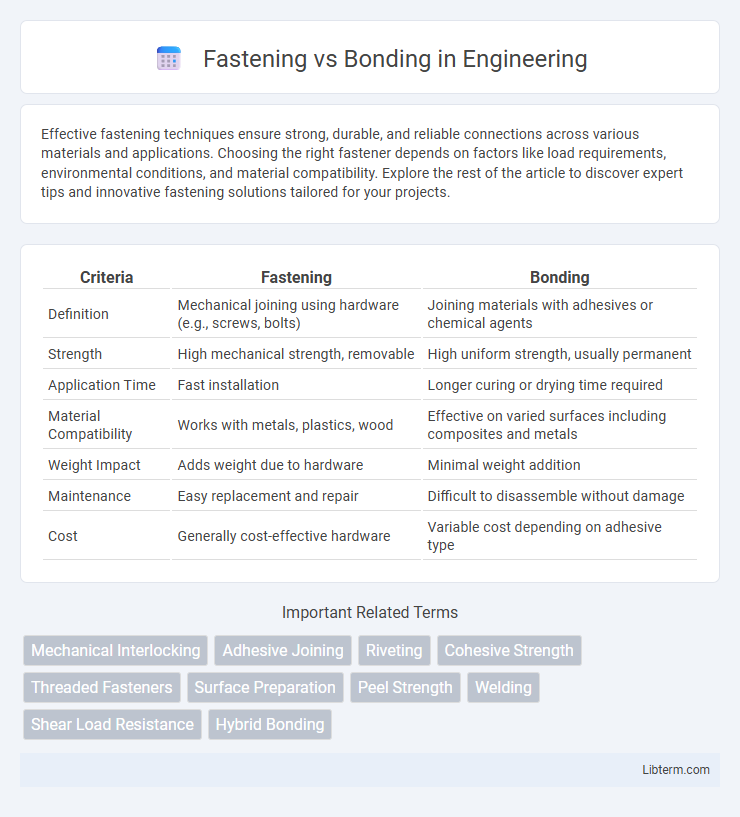

| Criteria | Fastening | Bonding |

|---|---|---|

| Definition | Mechanical joining using hardware (e.g., screws, bolts) | Joining materials with adhesives or chemical agents |

| Strength | High mechanical strength, removable | High uniform strength, usually permanent |

| Application Time | Fast installation | Longer curing or drying time required |

| Material Compatibility | Works with metals, plastics, wood | Effective on varied surfaces including composites and metals |

| Weight Impact | Adds weight due to hardware | Minimal weight addition |

| Maintenance | Easy replacement and repair | Difficult to disassemble without damage |

| Cost | Generally cost-effective hardware | Variable cost depending on adhesive type |

Introduction to Fastening and Bonding

Fastening and bonding are two primary methods used to join materials in manufacturing and construction. Fastening involves mechanical means such as screws, bolts, nails, and rivets to physically hold components together, offering strength and the possibility of disassembly. Bonding relies on adhesives and chemical agents to create a continuous bond between surfaces, providing uniform stress distribution and often improving aesthetic appeal without the need for holes or mechanical parts.

Defining Fastening: Methods and Applications

Fastening involves mechanically joining two or more components using devices such as screws, bolts, nails, or rivets, providing strong, often detachable connections ideal for structural and industrial applications. Common fastening methods include welding, soldering, and riveting, each suited to specific materials and load requirements in automotive, aerospace, and construction industries. Effective fastening ensures durability, ease of maintenance, and the ability to disassemble parts without compromising the integrity of the assembly.

Understanding Bonding: Techniques and Uses

Bonding involves joining materials using adhesives that create strong chemical or physical connections, providing uniform stress distribution and enhanced durability compared to mechanical fastening. Techniques such as epoxy resin, polyurethane, and cyanoacrylate bonding are commonly used in industries like aerospace, automotive, and electronics for lightweight and corrosion-resistant assemblies. Bonding is ideal for applications requiring smooth surfaces, vibration damping, and sealing properties, outperforming traditional fastening methods in both strength and aesthetics.

Key Differences Between Fastening and Bonding

Fastening involves mechanical methods such as screws, bolts, or rivets to join materials, providing easy disassembly and strong physical connections. Bonding relies on adhesive substances that create chemical or physical bonds between surfaces, offering uniform stress distribution and often enhancing material integrity without visible fasteners. Key differences include the permanence of the joint, with bonding typically being permanent and fastening allowing for removability, and the type of stress resistance, where fastening excels in shear strength while bonding provides better load distribution.

Strength and Durability: Which is Superior?

Fastening techniques such as bolting and riveting provide mechanical strength and are highly durable under dynamic loads and shear forces, making them ideal for structural applications requiring disassembly and reusability. Bonding methods using adhesives offer uniform stress distribution and superior resistance to fatigue and corrosion, enhancing long-term durability in environments with temperature fluctuations and vibrations. For maximum strength and longevity, hybrid approaches combining mechanical fastening with advanced adhesives often deliver superior performance in critical engineering and industrial applications.

Material Compatibility Considerations

Material compatibility is crucial in fastening and bonding processes to ensure structural integrity and durability. Fastening methods like screws or bolts require materials with sufficient thickness and hardness to avoid deformation or failure, while bonding depends heavily on the chemical and physical properties of surfaces for effective adhesion. Selecting appropriate adhesives or mechanical fasteners based on substrate materials such as metals, plastics, or composites optimizes performance and prevents issues like corrosion, delamination, or stress concentration.

Speed and Ease of Assembly

Fastening methods such as screws and bolts offer rapid assembly with immediate load-bearing capacity, enabling quick disassembly if needed, ideal for time-sensitive projects. Bonding techniques, including adhesives and glues, provide strong, uniform joints but require curing time, which can delay full strength realization and assembly completion. Speed and ease of assembly favor mechanical fastening when immediate handling is critical, while bonding excels in applications prioritizing seamless, permanent joins without the need for additional hardware.

Cost Comparison: Fastening vs Bonding

Fastening techniques, such as screws and bolts, typically involve lower initial material costs but higher labor expenses due to assembly time and potential maintenance. Bonding methods, including adhesives and epoxies, may require a higher upfront investment in specialized materials and surface preparation but often reduce labor costs and enhance production efficiency by streamlining assembly. Over the long term, bonding can provide cost savings through improved joint durability and reduced need for rework compared to mechanical fastening.

Industry-Specific Applications

Fastening techniques such as riveting, bolting, and welding are preferred in automotive and aerospace industries for their ability to provide high mechanical strength and ease of disassembly during maintenance. Bonding methods, including epoxy and polyurethane adhesives, dominate electronics and medical device manufacturing due to their capacity to join dissimilar materials with minimal stress and enhanced aesthetics. In construction, a combination of fastening and bonding improves structural integrity by balancing load distribution and environmental resistance.

Choosing the Right Method for Your Project

Selecting the appropriate fastening or bonding method depends on factors like material type, load requirements, and environmental conditions. Mechanical fasteners provide strong, removable connections ideal for metal or heavy components, while adhesives offer uniform stress distribution and aesthetic advantages for lightweight or irregular surfaces. Evaluating durability, assembly speed, and maintenance needs ensures optimal performance and longevity for your project.

Fastening Infographic

libterm.com

libterm.com