Reciprocating pumps use a piston or plunger to move fluid through a cylinder by creating pressure differences, making them ideal for precise flow control and high-pressure applications. These pumps are commonly used in industries such as oil and gas, chemical processing, and water treatment where consistent and reliable fluid delivery is essential. Explore the rest of the article to understand how a reciprocating pump can optimize your fluid handling needs.

Table of Comparison

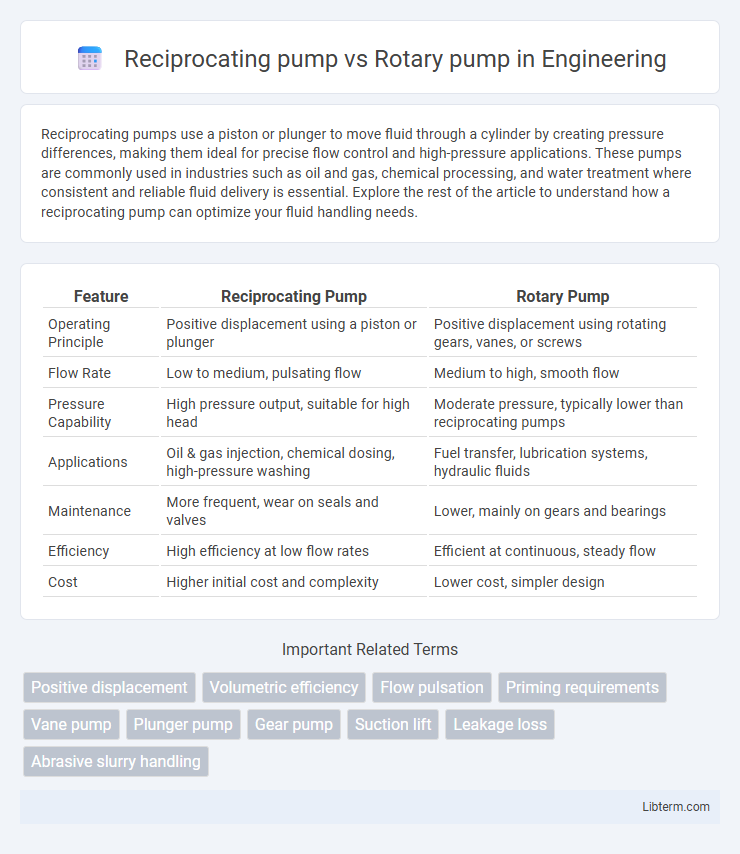

| Feature | Reciprocating Pump | Rotary Pump |

|---|---|---|

| Operating Principle | Positive displacement using a piston or plunger | Positive displacement using rotating gears, vanes, or screws |

| Flow Rate | Low to medium, pulsating flow | Medium to high, smooth flow |

| Pressure Capability | High pressure output, suitable for high head | Moderate pressure, typically lower than reciprocating pumps |

| Applications | Oil & gas injection, chemical dosing, high-pressure washing | Fuel transfer, lubrication systems, hydraulic fluids |

| Maintenance | More frequent, wear on seals and valves | Lower, mainly on gears and bearings |

| Efficiency | High efficiency at low flow rates | Efficient at continuous, steady flow |

| Cost | Higher initial cost and complexity | Lower cost, simpler design |

Introduction to Reciprocating and Rotary Pumps

Reciprocating pumps operate by using a piston or plunger to create suction and discharge pressure through cyclical motion, ideal for high-pressure, low-flow applications. Rotary pumps utilize rotating mechanisms such as gears, lobes, or vanes to move fluid continuously, offering smoother flow and suitability for low-pressure, high-flow systems. Both pump types are essential in industries like oil and gas, chemical processing, and wastewater treatment, where precise flow control and reliability are critical.

Working Principle of Reciprocating Pumps

Reciprocating pumps operate by converting the linear motion of a piston or plunger into fluid flow through a cylinder, creating alternating suction and discharge strokes. The suction stroke draws fluid into the cylinder through an inlet valve while the discharge stroke forces the fluid out via an outlet valve under high pressure. This positive displacement mechanism enables reciprocating pumps to handle high-pressure applications with precise flow control and minimal pulsation.

Working Principle of Rotary Pumps

Rotary pumps operate by trapping fluid between rotating elements and the pump casing, creating a consistent flow through positive displacement. Common types include gear, vane, and screw pumps, each using rotation to move fluid smoothly with minimal pulsation. This mechanism ensures high efficiency for viscous fluids and stable pressure output across various industrial applications.

Key Design Differences

Reciprocating pumps use a piston or plunger moving back and forth in a cylinder to create pressure and flow, offering precise volume control and high-pressure capability ideal for high-viscosity fluids and applications requiring exact dosing. Rotary pumps employ gears, lobes, screws, or vanes rotating continuously to transfer fluid smoothly, providing steady flow with lower pulsation, suitable for low to medium viscosity fluids and continuous operation. Key design differences include the linear versus rotational motion mechanism, pulsating versus steady flow output, and varying efficiency and maintenance requirements linked to the internal components and fluid handling capabilities.

Performance and Efficiency Comparison

Reciprocating pumps typically deliver higher pressure and superior efficiency for low flow rates due to their positive displacement mechanism, making them ideal for high-pressure applications. Rotary pumps generally offer smoother flow with lower pulsation and perform efficiently at higher flow rates but at lower pressures compared to reciprocating pumps. The choice between these pumps depends heavily on the specific operational demands, with reciprocating pumps favoring precision and rotary pumps excelling in continuous, moderate-pressure scenarios.

Applications of Reciprocating Pumps

Reciprocating pumps are widely used in applications requiring high pressure and precise flow control, such as in oil and gas injection, chemical dosing, and hydraulic systems. Their ability to handle viscous fluids and produce consistent, pulsation-free flow makes them ideal for water treatment plants and pharmaceutical manufacturing. Industrial sectors rely on reciprocating pumps for tasks involving slurry transfer, boiler feedwater, and high-pressure cleaning.

Applications of Rotary Pumps

Rotary pumps excel in handling viscous fluids, making them ideal for applications in chemical processing, oil and gas industries, and food production where smooth, continuous flow is essential. They are widely used in lubrication systems, fuel transfer, and hydraulic systems due to their ability to operate efficiently at high pressures with minimal pulsation. Common applications also include pumping syrups, adhesives, and heavy oils where maintaining fluid integrity and precise flow control is critical.

Maintenance Requirements and Reliability

Reciprocating pumps demand more frequent maintenance due to their complex valve systems and multiple moving parts that experience high wear and tear, impacting reliability over time. Rotary pumps feature simpler designs with fewer moving components, resulting in lower maintenance needs and enhanced reliability in continuous operation. Proper lubrication and timely inspection significantly improve the lifespan and efficiency of both pump types, but rotary pumps generally offer superior durability in corrosive or abrasive environments.

Advantages and Disadvantages

Reciprocating pumps offer high-pressure delivery and excellent efficiency at low flow rates, making them ideal for precise fluid handling in industries like oil and gas; however, they have complex mechanical parts that require frequent maintenance and generate pulsating flow. Rotary pumps provide smooth, continuous flow with lower maintenance and are better suited for handling viscous fluids in applications such as chemical processing, but they generally operate at lower pressures and can have reduced efficiency with high-viscosity fluids. Choosing between reciprocating and rotary pumps depends on the specific requirements for pressure, flow rate, fluid type, and maintenance capabilities.

Selecting the Right Pump for Your Needs

Reciprocating pumps excel in high-pressure, low-flow applications with precise flow control, making them ideal for chemical dosing and metering tasks. Rotary pumps offer steady, high-flow rates at lower pressures, suited for handling viscous fluids in industries like oil and food processing. Selecting the right pump depends on evaluating fluid characteristics, required pressure, flow rate, and maintenance preferences to ensure optimal performance and efficiency.

Reciprocating pump Infographic

libterm.com

libterm.com