Vat photopolymerization is an advanced 3D printing technology that uses a light source to selectively cure liquid resin in a vat, creating precise and highly detailed objects layer by layer. This method is widely used for applications requiring exceptional accuracy, such as dental models, jewelry, and prototypes. Discover more about how vat photopolymerization can enhance your manufacturing process in the rest of the article.

Table of Comparison

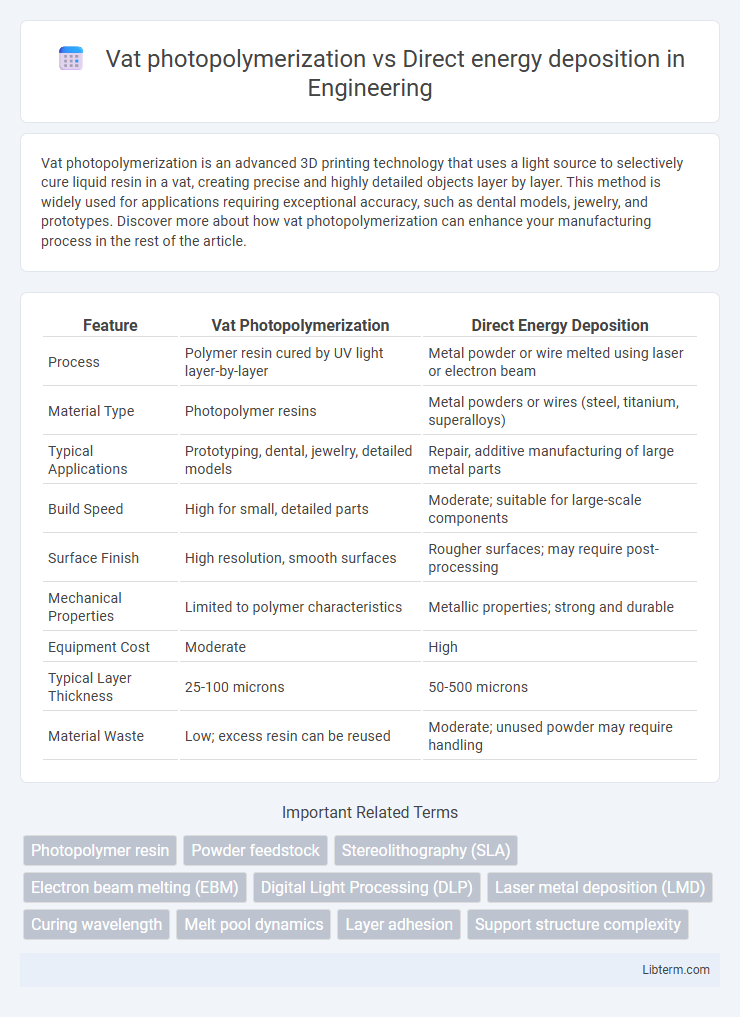

| Feature | Vat Photopolymerization | Direct Energy Deposition |

|---|---|---|

| Process | Polymer resin cured by UV light layer-by-layer | Metal powder or wire melted using laser or electron beam |

| Material Type | Photopolymer resins | Metal powders or wires (steel, titanium, superalloys) |

| Typical Applications | Prototyping, dental, jewelry, detailed models | Repair, additive manufacturing of large metal parts |

| Build Speed | High for small, detailed parts | Moderate; suitable for large-scale components |

| Surface Finish | High resolution, smooth surfaces | Rougher surfaces; may require post-processing |

| Mechanical Properties | Limited to polymer characteristics | Metallic properties; strong and durable |

| Equipment Cost | Moderate | High |

| Typical Layer Thickness | 25-100 microns | 50-500 microns |

| Material Waste | Low; excess resin can be reused | Moderate; unused powder may require handling |

Introduction to Additive Manufacturing Technologies

Vat photopolymerization utilizes a light source to selectively cure liquid photopolymer resin layer by layer, achieving high-resolution and intricate part details in additive manufacturing. Direct energy deposition employs focused thermal energy, such as laser or electron beam, to melt and fuse metallic powders or wires directly onto a substrate, enabling repair, cladding, and manufacturing of dense metal components. Both technologies serve distinct applications within additive manufacturing, with vat photopolymerization excelling in precision and surface finish, while direct energy deposition offers versatility in metal part fabrication and material properties.

Overview of Vat Photopolymerization

Vat photopolymerization is an additive manufacturing process that uses a light source to selectively cure liquid photopolymer resins layer by layer, creating highly detailed and smooth surface-finish parts. It excels in producing complex geometries with fine features and is widely used in industries like dental, jewelry, and prototyping due to its precision and speed. Key technologies under vat photopolymerization include stereolithography (SLA), digital light processing (DLP), and continuous liquid interface production (CLIP), each differing in light source and curing methods.

Fundamentals of Direct Energy Deposition

Direct Energy Deposition (DED) is an additive manufacturing process that uses focused thermal energy, such as a laser or electron beam, to melt and fuse materials as they are deposited layer-by-layer directly onto a substrate. Unlike Vat Photopolymerization, which cures liquid resin using UV light, DED enables the use of metal powders or wires, providing high deposition rates and the ability to repair or add features to existing components. Key parameters in DED include energy source power, feedstock delivery, and scanning speed, which influence microstructure, mechanical properties, and dimensional accuracy of the fabricated parts.

Material Compatibility and Selection

Vat photopolymerization excels with photopolymer resins, enabling high-resolution parts but is limited to photosensitive materials. Direct energy deposition supports a broader material range, including metals, ceramics, and composites, facilitating repair and hybrid manufacturing with thermally stable substrates. Material selection depends on the desired application, balancing precision of photopolymers against the versatility and structural integrity of metals in energy deposition.

Precision and Resolution Comparison

Vat photopolymerization offers superior precision and finer resolution with feature details often below 50 microns, making it ideal for intricate designs and smooth surface finishes. Direct energy deposition typically achieves lower resolution, with minimum feature sizes around 500 microns, due to the high-energy beam melting metallic powders, which results in rougher surface textures. The enhanced accuracy and detail of vat photopolymerization enable applications in industries like jewelry and dental, whereas direct energy deposition suits larger, structurally robust metal parts requiring less fine detail.

Build Speed and Production Efficiency

Vat photopolymerization offers high build speed for intricate, small-scale components due to rapid layer curing using UV light, optimizing production efficiency in fine-detail applications. Direct energy deposition provides greater production efficiency for larger, complex metal parts by depositing material and energy simultaneously, enabling faster buildup and repair processes. Comparing both, vat photopolymerization excels in speed for precision parts, while direct energy deposition enhances throughput in heavy-duty manufacturing tasks.

Surface Finish and Post-Processing Requirements

Vat photopolymerization delivers superior surface finish with smooth, detailed contours and minimal layer lines, significantly reducing the need for extensive post-processing. Direct energy deposition typically produces rougher surfaces with visible striations, requiring substantial machining or grinding to achieve desired surface quality. Post-processing for vat photopolymerization mainly involves cleaning and curing, whereas direct energy deposition demands more intensive finishing steps to improve texture and precision.

Application Areas and Industry Use Cases

Vat photopolymerization excels in producing high-precision, intricate prototypes and dental or jewelry models due to its fine layer resolution and smooth surface finish. Direct energy deposition is suited for repairing and fabricating large metal parts in aerospace, automotive, and defense industries, where adding material directly to existing components or creating complex metal structures is critical. The contrasting applications highlight vat photopolymerization's dominance in detailed polymer parts while direct energy deposition is pivotal for metal part restoration and additive manufacturing in heavy industries.

Cost Analysis and Scalability

Vat photopolymerization offers lower initial equipment costs and faster production cycles, making it cost-effective for small to medium-scale manufacturing of intricate parts. Direct energy deposition involves higher capital investment and operating expenses due to complex machinery and energy requirements but excels in scalability for large, customized metal components with superior mechanical properties. Cost analysis favors vat photopolymerization for prototyping and fine-detail applications, while direct energy deposition provides scalable solutions for industrial-scale production and repair tasks in aerospace and heavy engineering sectors.

Future Trends in Vat Photopolymerization and Direct Energy Deposition

Future trends in vat photopolymerization emphasize enhanced resin formulations with improved mechanical properties and biocompatibility, driving applications in medical devices and complex geometries. Direct energy deposition advances focus on real-time process monitoring and adaptive control systems, enabling precise fabrication and repair of metal components for aerospace and automotive industries. Integration of artificial intelligence and machine learning in both technologies promises optimized parameters and accelerated part qualification cycles.

Vat photopolymerization Infographic

libterm.com

libterm.com