Parallelism tolerance refers to the capacity of a computer system or processor to execute multiple instructions or tasks simultaneously without conflicts or errors. Higher parallelism tolerance improves overall performance by allowing efficient multitasking and resource utilization in multi-core CPUs and distributed computing environments. Discover how understanding parallelism tolerance can optimize your computing power and system efficiency by reading the rest of this article.

Table of Comparison

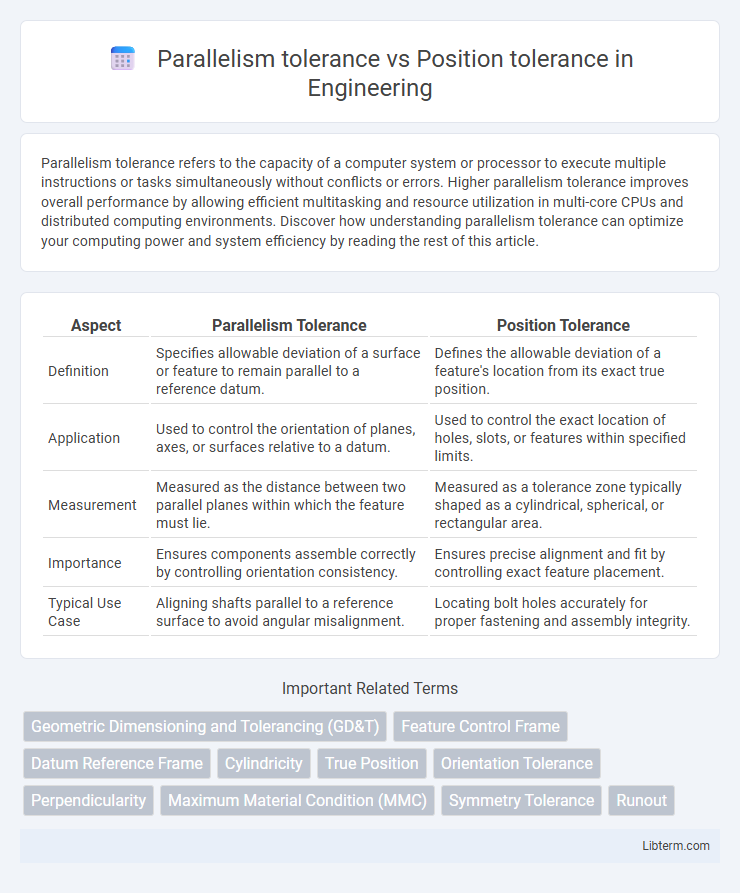

| Aspect | Parallelism Tolerance | Position Tolerance |

|---|---|---|

| Definition | Specifies allowable deviation of a surface or feature to remain parallel to a reference datum. | Defines the allowable deviation of a feature's location from its exact true position. |

| Application | Used to control the orientation of planes, axes, or surfaces relative to a datum. | Used to control the exact location of holes, slots, or features within specified limits. |

| Measurement | Measured as the distance between two parallel planes within which the feature must lie. | Measured as a tolerance zone typically shaped as a cylindrical, spherical, or rectangular area. |

| Importance | Ensures components assemble correctly by controlling orientation consistency. | Ensures precise alignment and fit by controlling exact feature placement. |

| Typical Use Case | Aligning shafts parallel to a reference surface to avoid angular misalignment. | Locating bolt holes accurately for proper fastening and assembly integrity. |

Understanding Parallelism Tolerance: Definition and Purpose

Parallelism tolerance defines the allowable variation in the orientation of a surface or feature relative to a datum axis or plane, ensuring precise alignment in mechanical assemblies. It controls how parallel a feature must be within specified limits to maintain functional performance and proper mating with other parts. Position tolerance, by contrast, regulates the exact location of a feature, but parallelism tolerance specifically addresses the degree of angular deviation allowable without compromising design intent.

Overview of Position Tolerance in Geometric Dimensioning

Position tolerance in Geometric Dimensioning controls the exact location of a feature relative to a datum, ensuring precise assembly and function of mechanical parts. It defines a tolerance zone where the center, axis, or median plane of the feature must lie, typically represented by a cylindrical or rectangular zone. This tolerance is crucial for managing variations in feature location without compromising fit, form, or function, distinguishing it from parallelism tolerance, which controls orientation rather than position.

Key Differences Between Parallelism and Position Tolerances

Parallelism tolerance controls the uniformity of a feature's orientation relative to a datum, ensuring surfaces or axes remain equidistant and aligned in the same direction. Position tolerance regulates the exact location within a tolerance zone, defining how far a feature's center, axis, or center plane can deviate from a specified datum. The key difference lies in parallelism focusing on directional consistency, while position tolerance emphasizes precise feature location within spatial limits.

How Parallelism Tolerance Is Measured and Applied

Parallelism tolerance is measured by the allowable deviation between two surfaces or features being equidistant along a specified axis, commonly quantified using a dial indicator or coordinate measuring machine (CMM) to assess uniform spacing relative to a datum. This tolerance ensures that one surface remains consistently parallel to another within a defined tolerance zone, critical in assemblies requiring precise alignment or motion. Position tolerance, by contrast, governs the exact location of a feature relative to datums but does not measure uniformity of orientation between surfaces.

Interpreting Position Tolerance on Technical Drawings

Position tolerance on technical drawings specifies the allowable deviation of a feature's exact location relative to a datum, ensuring proper assembly and function. Parallelism tolerance controls the orientation of a feature in relation to a datum plane or axis, limiting the permissible angular variation. Interpreting position tolerance requires understanding its geometric tolerance zone, often cylindrical or rectangular, which defines the acceptable location range around true position coordinates.

Common Applications for Parallelism Tolerance in Manufacturing

Parallelism tolerance ensures that two surfaces or features remain consistently equidistant and parallel, which is critical in manufacturing parts that require smooth assembly and precise motion control. Common applications include shaft and bearing alignment, where maintaining parallel surfaces reduces wear and improves operational efficiency in engines and gearboxes. Position tolerance, in contrast, controls the exact location of features but does not inherently guarantee parallelism, making parallelism tolerance essential for components requiring parallel alignment for function and durability.

Critical Uses of Position Tolerance in Engineering Design

Position tolerance is crucial in engineering design for ensuring precise location of features, which directly affects assembly fit and functionality in mechanical components. Unlike parallelism tolerance that controls orientation, position tolerance tightly manages the exact coordinates of holes, pins, and slots to prevent misalignment and ensure interchangeability. Critical uses include aligning mating parts in aerospace and automotive industries where even minor deviations can compromise performance and safety.

Impact of Parallelism and Position Tolerances on Part Functionality

Parallelism tolerance ensures that a surface or feature remains equidistant and aligned relative to a datum plane or axis, directly affecting how parts fit and move together in assemblies by preventing misalignment. Position tolerance controls the allowable deviation of a feature's location, crucial for ensuring proper mating and functional interaction between components in mechanical systems. The impact of parallelism and position tolerances on part functionality is significant because improper control can lead to assembly difficulties, increased wear, and compromised mechanical performance due to misaligned or incorrectly located features.

Best Practices for Specifying Parallelism vs Position Tolerance

Best practices for specifying parallelism tolerance vs position tolerance emphasize clear functional requirements; parallelism tolerance controls the angular deviation between surfaces relative to a datum, ensuring precise alignment, while position tolerance governs the exact location or axis of a feature within a defined tolerance zone. Specifying parallelism is most effective when the requirement focuses on orientation without strict positional constraints, often used for features like shafts or plates that must remain parallel but not necessarily fixed in place. Position tolerance is preferred for critical assemblies demanding precise feature location to guarantee proper fit and function, such as hole locations in mating parts, ensuring robust design intent and manufacturability.

Choosing the Right Tolerance for Your Project: Parallelism or Position

Parallelism tolerance ensures features maintain consistent orientation relative to a datum, critical for parts requiring uniform alignment, such as shafts or sliding components. Position tolerance controls the exact location of features, essential in assemblies where precise fit and function depend on accurate placement of holes or pins. Selecting between parallelism and position tolerances depends on whether orientation control or exact feature location is paramount to the functionality and assembly integrity of your project.

Parallelism tolerance Infographic

libterm.com

libterm.com