Plug valve offers a compact and efficient solution for controlling fluid flow in pipelines, featuring a simple design with a cylindrical or conical plug that rotates to open or close the passage. Known for quick operation and low maintenance, plug valves are ideal for applications requiring reliable sealing and minimal leakage, especially in high-pressure systems. Discover how choosing the right plug valve can enhance Your system's performance by exploring the detailed insights in the rest of the article.

Table of Comparison

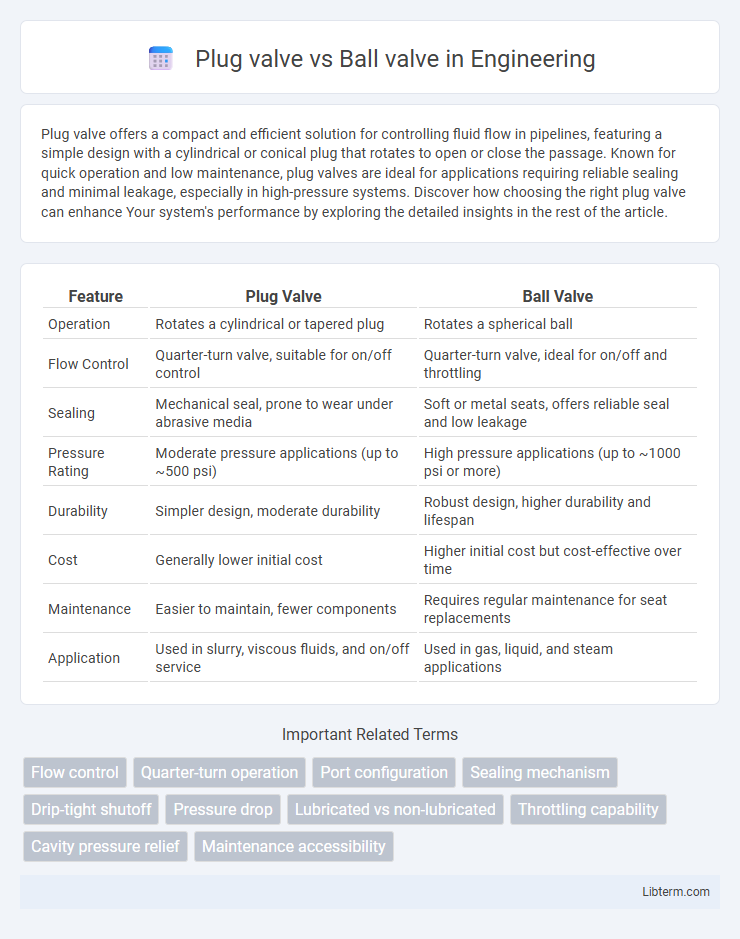

| Feature | Plug Valve | Ball Valve |

|---|---|---|

| Operation | Rotates a cylindrical or tapered plug | Rotates a spherical ball |

| Flow Control | Quarter-turn valve, suitable for on/off control | Quarter-turn valve, ideal for on/off and throttling |

| Sealing | Mechanical seal, prone to wear under abrasive media | Soft or metal seats, offers reliable seal and low leakage |

| Pressure Rating | Moderate pressure applications (up to ~500 psi) | High pressure applications (up to ~1000 psi or more) |

| Durability | Simpler design, moderate durability | Robust design, higher durability and lifespan |

| Cost | Generally lower initial cost | Higher initial cost but cost-effective over time |

| Maintenance | Easier to maintain, fewer components | Requires regular maintenance for seat replacements |

| Application | Used in slurry, viscous fluids, and on/off service | Used in gas, liquid, and steam applications |

Introduction to Plug Valves and Ball Valves

Plug valves and ball valves are essential components in fluid control systems, designed to regulate flow through rotation of a cylindrical or spherical element. Plug valves use a cylindrical or conically tapered plug with a hollow passage to control fluid flow, offering quick shut-off and minimal pressure drop. Ball valves feature a spherical ball with a central bore that rotates within the valve body, providing reliable sealing and ease of operation in both on/off and throttling applications.

Overview of Valve Design and Construction

Plug valves and ball valves differ primarily in their internal design and construction; plug valves use a cylindrical or tapered plug with one or more hollow passageways to control flow, while ball valves employ a spherical ball with a central bore. The plug valve's design facilitates quick quarter-turn operation and good throttling capabilities, whereas ball valves provide tight shut-off and minimal leakage with a smooth, rotary motion. Construction materials typically range from metal alloys like stainless steel and brass to plastics, selected based on pressure, temperature, and media compatibility requirements.

Key Functional Differences

Plug valves feature a cylindrical or tapered plug that rotates within the valve body to control flow, providing quick on/off operation with low-pressure drop and effective sealing for slurry or viscous fluids. Ball valves use a spherical ball with a hole through its center, offering precise flow control, excellent sealing, and suitability for high-pressure and high-temperature applications. Key functional differences include plug valves' simpler design for throttling and handling abrasive fluids, while ball valves excel in tight shutoff and versatility across diverse industrial processes.

Flow Control and Sealing Mechanisms

Plug valves provide precise flow control through their cylindrical or conical plugs that rotate within the valve body, offering quick quarter-turn operation and tight shutoff. Ball valves use a spherical ball with a central bore to regulate flow, ensuring efficient sealing by aligning the bore with the pipeline for full flow or perpendicular to stop flow completely. Sealing in plug valves relies on tapered plugs and matching seats that compress to prevent leaks, while ball valves utilize resilient seats that press against the ball to maintain bubble-tight sealing under various pressures.

Installation and Maintenance Requirements

Plug valves require straightforward installation, often needing minimal alignment due to their simple quarter-turn mechanism, making them ideal for moderate flow control applications. Ball valves demand precise alignment during installation to ensure a tight seal and prevent leakage, especially in high-pressure systems, which can increase setup complexity. Maintenance for plug valves is generally simpler with fewer moving parts and less risk of wear, whereas ball valves may require frequent inspection and replacement of seals and seats to maintain optimal performance.

Performance in High-Pressure Applications

Plug valves offer excellent performance in high-pressure applications due to their robust design and ability to provide tight shutoff under extreme conditions. Ball valves also perform well under high pressure, featuring a spherical closure element that ensures minimal leakage and smooth operation even at elevated pressures. However, ball valves typically provide better durability and ease of maintenance, making them preferable in systems with frequent cycling and pressure fluctuations.

Suitability for Different Media and Environments

Plug valves are highly suitable for handling viscous fluids, slurries, and gases in applications requiring tight shut-off, especially in corrosive or abrasive environments due to their simple design and ease of maintenance. Ball valves excel in controlling clean liquids, gases, and steam, offering excellent performance in high-pressure and high-temperature conditions, making them ideal for chemical, oil, and gas industries. Both valve types provide reliable sealing, but ball valves are preferred for precise flow control and rapid operation in sterile or high-purity environments.

Advantages and Disadvantages of Plug Valves

Plug valves offer quick quarter-turn operation and a simple design that minimizes pressure drop and leakage, making them suitable for applications requiring rapid shutoff and frequent operation. Their compact structure and fewer parts reduce maintenance needs, but they can experience wear and increased torque over time due to metal-to-metal contact, limiting their use in abrasive or high-pressure environments. While ball valves generally provide better sealing and durability under high pressure, plug valves excel in handling viscous fluids and slurries with minimal flow resistance.

Pros and Cons of Ball Valves

Ball valves offer reliable tight shut-off capabilities and are highly durable, making them ideal for high-pressure and high-temperature applications. Their quick quarter-turn operation ensures efficient flow control, but they can be prone to wear and tear in abrasive media. Although ball valves have low pressure drop and minimal leakage, they may require more maintenance compared to plug valves when handling slurry or viscous fluids.

Choosing the Right Valve: Plug vs Ball Valve

Choosing the right valve depends on application requirements such as flow control precision, pressure rating, and maintenance needs. Plug valves offer quick shutoff with fewer moving parts and are ideal for slurry or viscous fluids, while ball valves provide tight sealing and durability, making them suitable for high-pressure, high-temperature environments. Consider factors like fluid type, operational frequency, and installation space to determine if a plug valve or ball valve optimally balances performance and cost-efficiency.

Plug valve Infographic

libterm.com

libterm.com