Underground cables offer a reliable and protected means of transmitting electricity or data, minimizing exposure to weather-related damage and external interference. They require careful installation and maintenance to prevent faults and ensure long-term performance in various soil and environmental conditions. Discover the key benefits, types, and installation techniques of underground cables by reading the rest of this article.

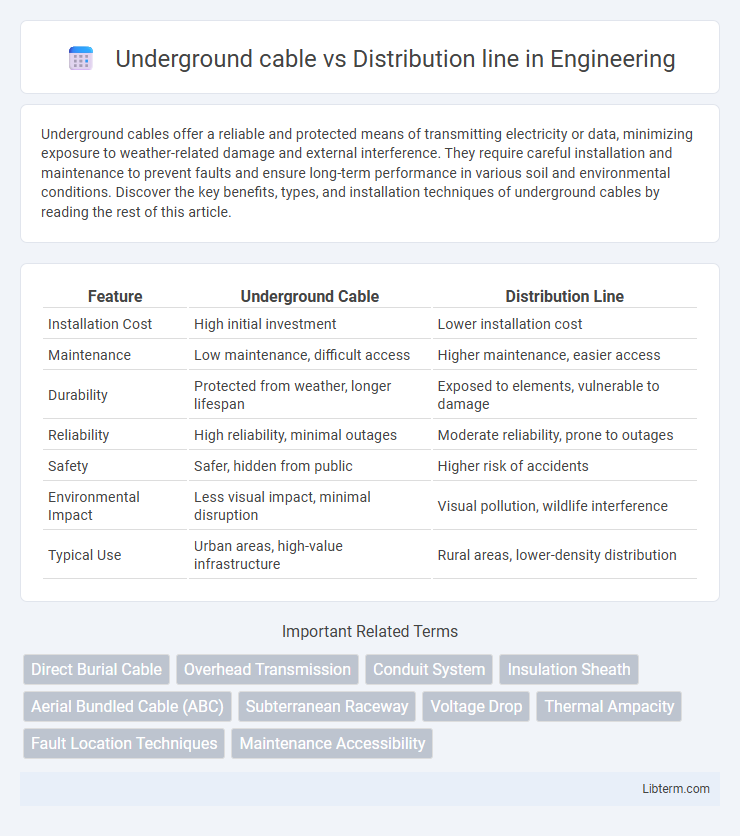

Table of Comparison

| Feature | Underground Cable | Distribution Line |

|---|---|---|

| Installation Cost | High initial investment | Lower installation cost |

| Maintenance | Low maintenance, difficult access | Higher maintenance, easier access |

| Durability | Protected from weather, longer lifespan | Exposed to elements, vulnerable to damage |

| Reliability | High reliability, minimal outages | Moderate reliability, prone to outages |

| Safety | Safer, hidden from public | Higher risk of accidents |

| Environmental Impact | Less visual impact, minimal disruption | Visual pollution, wildlife interference |

| Typical Use | Urban areas, high-value infrastructure | Rural areas, lower-density distribution |

Introduction to Underground Cables and Distribution Lines

Underground cables consist of insulated conductors buried beneath the ground to transmit electricity efficiently and protect against environmental hazards, offering enhanced safety and reliability compared to overhead options. Distribution lines, typically overhead, deliver electricity from substations to consumers, utilizing poles and wires exposed to weather conditions. The choice between underground cables and distribution lines affects maintenance costs, aesthetics, and vulnerability to outages in electrical distribution systems.

Basic Construction and Design Differences

Underground cables are insulated conductors placed below ground level, typically encased in protective conduits or ducts to prevent physical damage and moisture infiltration, whereas distribution lines consist of overhead wires supported by poles or towers for easy access and maintenance. Underground cables require more robust insulation materials such as cross-linked polyethylene (XLPE) or ethylene propylene rubber (EPR) and have compact, sealed designs to withstand soil pressure and environmental stress. Distribution lines feature exposed conductors made of aluminum or copper, with simpler construction focusing on mechanical support and electrical clearance from surrounding elements.

Installation Processes and Requirements

Underground cables require trenching, conduit installation, and careful soil backfilling to protect insulation, demanding extensive excavation and specialized equipment, whereas distribution lines typically involve overhead pole setting and wire stringing with fewer site disturbances. Installation of underground cables mandates precise handling of cable joints, splices, and terminations in enclosed environments, ensuring moisture and mechanical stress protection, while overhead distribution lines prioritize clearance, pole strength, and weather resilience. Regulatory compliance for underground installations includes detailed permits for excavation and environmental impact, contrasting with distribution lines that focus on right-of-way agreements and pole safety standards.

Cost Comparison: Initial and Long-Term Expenses

Underground cables typically involve higher initial costs due to excavation, insulation, and specialized installation requirements, while overhead distribution lines are generally more affordable to install. Long-term expenses for underground cables tend to be lower, as they experience less damage from weather and require less frequent maintenance compared to overhead lines that are exposed to environmental factors. Utility companies must weigh higher upfront investments against reduced repair costs and improved reliability over the lifespan of underground systems.

Reliability and Maintenance Needs

Underground cables offer higher reliability due to reduced exposure to weather-related disruptions such as storms and falling trees, minimizing outage frequency and duration. Maintenance requirements for underground cables are generally lower in terms of routine inspections but can be more complex and costly when faults occur, requiring specialized equipment and excavation. In contrast, overhead distribution lines experience more frequent faults and maintenance events due to environmental exposure but allow easier access for repairs and inspections, making ongoing maintenance faster and more straightforward.

Environmental Impact and Land Use

Underground cables minimize environmental disruption by reducing surface land use and preserving natural habitats, unlike overhead distribution lines that require extensive right-of-way clearance and can fragment ecosystems. The insulation and burial of underground cables protect wildlife from electrical hazards and reduce visual pollution, enhancing biodiversity conservation. Although more costly initially, underground installation offers long-term advantages in maintaining environmental integrity and reducing the risk of outages from weather-related damage.

Safety Considerations and Public Health

Underground cables significantly reduce the risk of electrical hazards, such as electrocution and fire incidents, compared to overhead distribution lines, enhancing public safety in residential and urban areas. The insulation and protective sheathing of underground cables minimize exposure to environmental factors, reducing maintenance-related accidents and electrical faults that can pose health risks. Underground installation also lowers electromagnetic field (EMF) exposure for communities, potentially mitigating long-term health concerns linked to EMF emitted by overhead distribution lines.

Performance in Extreme Weather Conditions

Underground cables offer superior performance in extreme weather conditions by being insulated from wind, ice, and storms, reducing outages and enhancing reliability. Distribution lines, exposed to environmental elements, are more susceptible to damage from high winds, ice accumulation, and lightning strikes, leading to frequent interruptions. The underground approach also minimizes maintenance needs during adverse weather, ensuring consistent power delivery and improved system resilience.

Urban vs Rural Applications

Underground cables are preferred in urban applications due to limited space, aesthetics, and reduced exposure to weather-related damage, enhancing system reliability and safety in densely populated areas. Distribution lines remain dominant in rural settings because they offer cost-effective installation and maintenance over long distances with fewer physical obstacles. Urban underground systems often require advanced insulation and thermal management, while rural distribution lines emphasize robustness and ease of repair.

Future Trends and Technological Innovations

Underground cables are increasingly preferred for urban distribution networks due to advancements in insulation materials and real-time monitoring systems that enhance durability and fault detection. Future trends indicate a shift towards smart grids integrating underground cables with IoT-enabled sensors, allowing predictive maintenance and improved energy efficiency. Distribution lines continue evolving with hybrid designs combining overhead and underground elements to optimize cost and reliability in diverse environments.

Underground cable Infographic

libterm.com

libterm.com