Bearing refers to the direction or position of one point relative to another, often expressed in degrees measured clockwise from the north. Accurate understanding of bearings is essential for navigation, surveying, and engineering to ensure precise location and alignment. Explore the article to enhance Your knowledge of bearings and their practical applications.

Table of Comparison

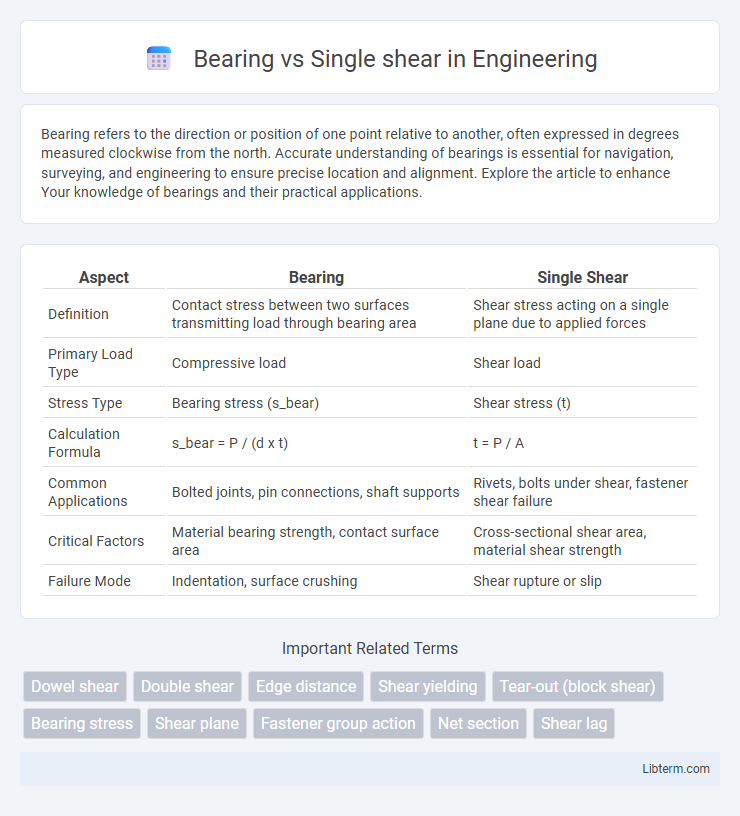

| Aspect | Bearing | Single Shear |

|---|---|---|

| Definition | Contact stress between two surfaces transmitting load through bearing area | Shear stress acting on a single plane due to applied forces |

| Primary Load Type | Compressive load | Shear load |

| Stress Type | Bearing stress (s_bear) | Shear stress (t) |

| Calculation Formula | s_bear = P / (d x t) | t = P / A |

| Common Applications | Bolted joints, pin connections, shaft supports | Rivets, bolts under shear, fastener shear failure |

| Critical Factors | Material bearing strength, contact surface area | Cross-sectional shear area, material shear strength |

| Failure Mode | Indentation, surface crushing | Shear rupture or slip |

Introduction to Bearing and Single Shear

Bearings provide support for rotating shafts by reducing friction between moving parts, commonly used in mechanical systems to enhance efficiency and durability. Single shear involves a scenario where a fastener or structural member resists a load applied in one plane, resulting in a single shear plane where failure could occur. Understanding the distinction between bearing forces, which act on surfaces in contact, and single shear forces, which act along a cross-sectional area, is critical for designing safe and reliable mechanical connections.

Definitions: Bearing vs Single Shear

Bearing refers to the contact stress between two mating components where one surface supports the load transmitted through the other, typically observed in bolted or pinned connections. Single shear describes the failure mode in a structural element where a load causes a shear force acting on a single plane, commonly seen in bolts or rivets subjected to transverse loading. Understanding bearing emphasizes surface contact pressure, while single shear highlights the internal resistance along one shear plane.

Structural Applications and Importance

Bearing and single shear are critical concepts in structural engineering, affecting load transfer and joint performance. Bearing stress occurs when a force is applied perpendicular to a surface, ensuring stability in bolted or pinned connections by distributing loads over a larger area to prevent material crushing. Single shear involves a force that tends to cause one part of a member to slide past another, commonly seen in riveted or bolted joints, making it essential for assessing shear strength and ensuring the durability of structural connections.

Load Distribution in Bearing and Shear

Bearing load distribution involves surface contact where force spreads over the contact area between connected parts, reducing stress concentration and enhancing structural integrity. Single shear load distribution concentrates force along a single shear plane, leading to higher localized stress that requires precise calculation to prevent failure. Optimizing bearing conditions improves load transfer efficiency, while understanding shear plane characteristics is critical for accurate strength assessment in joint design.

Failure Modes Comparison

Bearing failure occurs when the fastener deforms by compressive stress, leading to elongation of bolt holes and material crushing around the hole; this mode typically allows some load redistribution before complete failure. Single shear failure happens when the fastener or the sheet material shears across the cross-section, causing a clean fracture along the shear plane under direct shear stress. Comparing both, bearing failure is often more desirable due to its ductile characteristics and warning signs, whereas single shear failure is brittle and sudden, posing higher risk for catastrophic structural damage.

Design Considerations and Criteria

Bearing and single shear are critical considerations in structural design, with bearing involving the contact stress between connected elements and single shear focusing on the shearing force that acts on a single plane through a fastener or material. Design must ensure adequate bearing area to prevent crushing or deformation, while shear capacity is calculated based on material properties and cross-sectional area to avoid failure. Factors such as load type, connection geometry, and material strength govern the selection of appropriate design criteria for both bearing and single shear conditions.

Material Selection for Bearing and Shear

Material selection for bearing applications prioritizes high compressive strength, excellent wear resistance, and fatigue durability to withstand heavy loads and reduce surface deformation. In contrast, materials for single shear scenarios require superior tensile strength, ductility, and toughness to resist failure under concentrated shear stresses and avoid brittle fracture. Common bearing materials include hardened steels and bronze alloys, while single shear components often utilize high-strength alloy steels or composites engineered for enhanced shear performance.

Calculation Methods and Formulas

Bearing stress is calculated using the formula s_bearing = F / (d x t), where F is the applied load, d is the pin diameter, and t is the thickness of the material being loaded. Single shear stress is determined by t_shear = F / A_shear, where F is the shear force and A_shear is the cross-sectional area perpendicular to the force; typically A_shear = t x w for rectangular sections. Design standards often compare these stresses to allowable limits to ensure safe joint performance under bearing and single shear conditions.

Common Mistakes and Pitfalls

Common mistakes in bearing versus single shear analyses include misidentifying the load transfer mechanism, leading to incorrect failure mode assumptions. Overlooking the distinction between distributed contact stress in bearing and concentrated shear stress in single shear often results in underestimating stress concentrations or miscalculating joint capacity. Failure to account for factors like bolt-hole clearance and material bearing strength frequently causes premature failure or overly conservative designs.

Conclusion: Choosing Between Bearing and Single Shear

Choosing between bearing and single shear depends on the specific load conditions and design requirements of a mechanical joint. Bearing provides better load distribution and higher strength under compressive forces, making it ideal for applications with heavy and fluctuating loads. Single shear is simpler and more cost-effective but best suited for lighter loads with limited stress concentrations.

Bearing Infographic

libterm.com

libterm.com