Butterfly valves regulate fluid flow efficiently through a rotating disc mechanism, offering quick shutoff and minimal pressure drop. Their compact design and versatility make them ideal for applications in water supply, HVAC systems, and chemical processing. Discover how choosing the right butterfly valve can optimize Your system's performance by reading the full article.

Table of Comparison

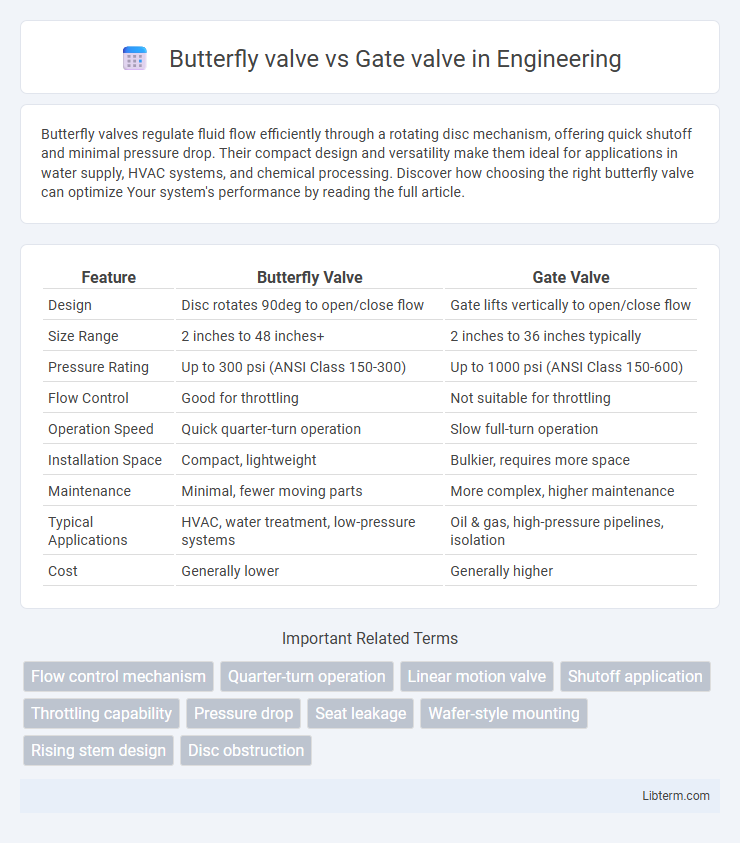

| Feature | Butterfly Valve | Gate Valve |

|---|---|---|

| Design | Disc rotates 90deg to open/close flow | Gate lifts vertically to open/close flow |

| Size Range | 2 inches to 48 inches+ | 2 inches to 36 inches typically |

| Pressure Rating | Up to 300 psi (ANSI Class 150-300) | Up to 1000 psi (ANSI Class 150-600) |

| Flow Control | Good for throttling | Not suitable for throttling |

| Operation Speed | Quick quarter-turn operation | Slow full-turn operation |

| Installation Space | Compact, lightweight | Bulkier, requires more space |

| Maintenance | Minimal, fewer moving parts | More complex, higher maintenance |

| Typical Applications | HVAC, water treatment, low-pressure systems | Oil & gas, high-pressure pipelines, isolation |

| Cost | Generally lower | Generally higher |

Introduction to Butterfly Valves and Gate Valves

Butterfly valves feature a rotating disc to regulate flow, offering quick operation and compact design suitable for large pipe diameters. Gate valves use a sliding gate mechanism to provide a straight-through flow path, excelling in fully open or closed positions with minimal pressure drop. Both valves are essential in industrial applications, with butterfly valves favored for throttling and gate valves preferred for isolation tasks.

Basic Design and Structure Differences

Butterfly valves feature a compact design with a rotating disc mounted on a central shaft that turns 90 degrees to control flow, making them lightweight and suitable for quick operation. Gate valves consist of a rising or non-rising stem that lifts a wedge-shaped gate vertically to open or close the passage, providing a straight-through flow with minimal pressure drop when fully open. The butterfly valve's thin disc partially obstructs flow when open, unlike the gate valve's full bore design, which allows unimpeded fluid passage.

Operating Mechanism Comparison

Butterfly valves utilize a rotating disc mechanism that turns 90 degrees to regulate fluid flow, providing quick operation and compact design ideal for throttling applications. Gate valves operate with a rising or non-rising wedge-shaped gate that moves vertically to start or stop flow, offering minimal pressure drop but slower operation suited for on/off control. The butterfly valve's quarter-turn action allows faster operation and lighter weight, whereas the gate valve's linear motion delivers a tight seal in fully open or closed positions.

Flow Control and Throttling Capabilities

Butterfly valves provide precise flow control and throttling capabilities due to their quarter-turn operation and disc design, making them ideal for regulating flow in large-diameter pipelines. Gate valves, designed primarily for on/off service, offer minimal throttling capabilities and are less effective for flow modulation because the wedge-shaped gate either fully opens or closes the flow path. The streamlined disc of butterfly valves enables quicker adjustments and better performance in applications requiring variable flow rates compared to the linear motion of gate valves.

Pressure and Temperature Suitability

Butterfly valves excel in handling moderate pressure levels up to around 300 psi and temperatures typically ranging from -40degF to 450degF, making them ideal for HVAC and water distribution systems. Gate valves are better suited for higher pressure environments exceeding 600 psi and can withstand a broader temperature spectrum, often up to 800degF, which is common in steam and oil pipeline applications. The selection between the two depends heavily on operational pressure and temperature demands to ensure valve integrity and performance.

Installation Space and Weight Considerations

Butterfly valves offer a compact design with significantly lower weight compared to gate valves, making them ideal for installations with limited space and weight constraints. Gate valves require a larger footprint and heavier materials due to their fully opening gate mechanism, increasing installation complexity and structural support needs. Choosing butterfly valves reduces piping stress and facilitates easier maintenance in confined or weight-sensitive environments.

Maintenance and Durability

Butterfly valves require less maintenance due to their simpler design and fewer moving parts, making them less prone to wear and easier to service in tight spaces. Gate valves offer higher durability in high-pressure and high-temperature applications but demand regular maintenance to prevent stem corrosion and sealing issues. Choosing between the two depends on the specific operational environment and maintenance capabilities.

Cost and Economic Factors

Butterfly valves generally offer lower initial costs and reduced maintenance expenses due to their simpler design and fewer moving parts, making them economically favorable for large-diameter pipelines. Gate valves tend to have higher upfront costs and require more maintenance over time, but they provide a tight seal ideal for applications demanding minimal leakage. The choice between the two valves hinges on balancing budget constraints with operational needs, where butterfly valves excel in cost-efficiency while gate valves justify their expense through performance in high-pressure systems.

Typical Applications and Industry Usage

Butterfly valves are commonly used in applications requiring quick shutoff and flow regulation, such as water distribution, HVAC, and chemical processing industries due to their lightweight design and compact size. Gate valves excel in industries like oil and gas, power generation, and petrochemical sectors where full flow and minimal pressure drop are critical, handling high-pressure and high-temperature conditions effectively. Both valve types are essential for controlling fluid flow but are selected based on specific requirements like operating pressure, space constraints, and fluid characteristics.

Pros and Cons: Butterfly Valve vs Gate Valve

Butterfly valves offer quick operation, compact design, and lower cost, making them ideal for applications requiring frequent throttling and space savings, but they may cause pressure drops and are less suited for high-pressure systems. Gate valves provide excellent sealing and minimal flow resistance, suitable for on/off control in high-pressure environments, though they are bulkier, slower to operate, and more expensive. Choosing between butterfly and gate valves depends on system requirements such as pressure, flow control precision, and budget constraints.

Butterfly valve Infographic

libterm.com

libterm.com