A ball joint is a crucial component in vehicle suspension systems that allows for smooth movement and steering flexibility by connecting control arms to the steering knuckles. Proper maintenance of ball joints ensures vehicle safety and prevents uneven tire wear or suspension damage. Explore the rest of this article to learn how to identify ball joint issues and keep your vehicle performing at its best.

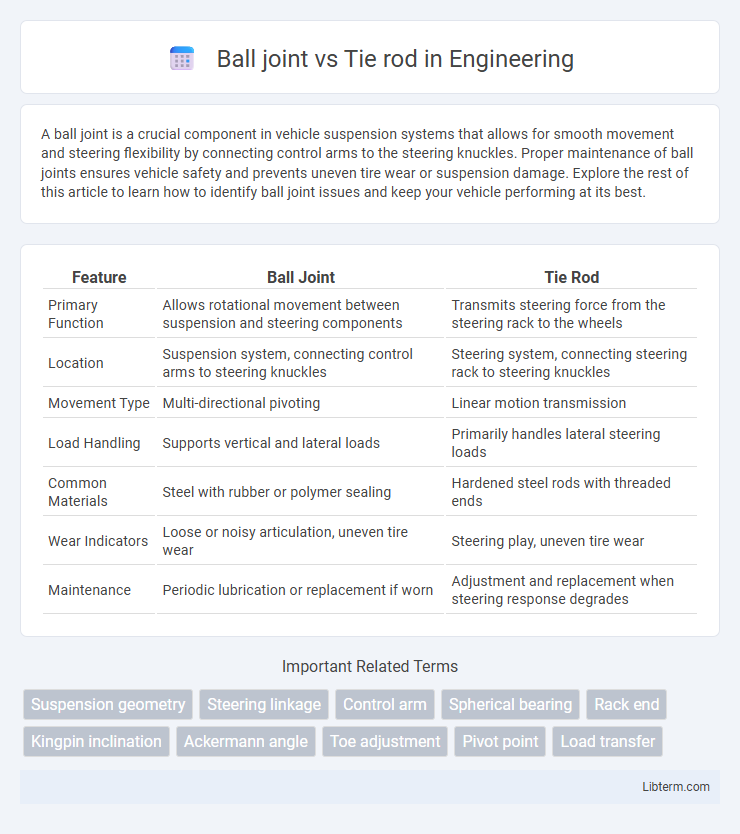

Table of Comparison

| Feature | Ball Joint | Tie Rod |

|---|---|---|

| Primary Function | Allows rotational movement between suspension and steering components | Transmits steering force from the steering rack to the wheels |

| Location | Suspension system, connecting control arms to steering knuckles | Steering system, connecting steering rack to steering knuckles |

| Movement Type | Multi-directional pivoting | Linear motion transmission |

| Load Handling | Supports vertical and lateral loads | Primarily handles lateral steering loads |

| Common Materials | Steel with rubber or polymer sealing | Hardened steel rods with threaded ends |

| Wear Indicators | Loose or noisy articulation, uneven tire wear | Steering play, uneven tire wear |

| Maintenance | Periodic lubrication or replacement if worn | Adjustment and replacement when steering response degrades |

Introduction to Ball Joints and Tie Rods

Ball joints connect the steering knuckles to the control arms, allowing smooth pivoting and suspension movement in vehicles. Tie rods link the steering rack to the steering arms, crucial for translating steering wheel rotation into wheel direction changes. Both components are essential for precise steering control and vehicle stability.

Function and Importance in Vehicle Steering

Ball joints serve as pivot points connecting the control arms to the steering knuckles, enabling smooth and flexible wheel movement crucial for precise steering and suspension articulation. Tie rods transmit steering force from the steering rack to the wheels, directly controlling wheel alignment and direction changes for accurate vehicle maneuverability. Both components are essential for safe and responsive steering, with ball joints ensuring suspension flexibility and tie rods providing precise directional control.

Ball Joint Overview: Structure and Role

The ball joint consists of a spherical bearing that connects the control arm to the steering knuckle, allowing multidirectional movement essential for steering and suspension articulation. Its structure includes a metal housing, a bearing stud, and a protective dust boot to prevent contamination and ensure durability. Serving as a pivot point, the ball joint plays a critical role in maintaining vehicle stability, handling, and smooth tire movement over varied road conditions.

Tie Rod Overview: Structure and Purpose

Tie rods are essential automotive components that connect the steering gear to the wheel assembly, transmitting steering force to enable precise wheel movement. Their structure typically includes a long metal rod with adjustable ends, allowing for alignment adjustments and ensuring optimal steering geometry. Designed to withstand tensile forces, tie rods play a critical role in vehicle handling, stability, and steering responsiveness.

Key Differences Between Ball Joints and Tie Rods

Ball joints serve as pivot points connecting the control arms to the steering knuckles, allowing smooth movement and suspension articulation. Tie rods link the steering rack to the steering arm, transmitting steering input to the wheels for directional control. Unlike tie rods that primarily handle steering alignment, ball joints support both steering and suspension dynamics, bearing significant load and enabling vertical movement of the wheels.

Symptoms of Ball Joint Failure

Symptoms of ball joint failure include uneven tire wear, clunking noises while driving over bumps, and steering wandering or looseness. A deteriorating ball joint can cause suspension misalignment, resulting in poor vehicle handling and increased vibration through the steering wheel. Early detection of these signs is critical to maintaining safety and preventing further damage to the suspension system.

Signs of Worn Tie Rods

Worn tie rods often cause uneven tire wear, steering wheel vibration, and loose or unresponsive steering, indicating compromised vehicle control. A clicking noise when turning or excessive play in the steering wheel can also signal deteriorated tie rods needing prompt replacement. Diagnosis through a mechanic's inspection is crucial to prevent alignment issues and ensure safe handling.

Maintenance Tips for Ball Joints and Tie Rods

Regular inspection of ball joints and tie rods is crucial for vehicle safety and performance, with attention to signs of wear such as looseness, noise, or uneven tire wear. Proper lubrication of ball joints can extend their lifespan, while tie rods should be checked for secure fittings and alignment issues to prevent steering problems. Timely replacement of damaged components ensures smooth handling and reduces the risk of suspension failure.

Replacement Costs and Factors to Consider

Ball joint replacement costs range from $150 to $350, influenced by vehicle type and labor intensity, while tie rod replacement typically costs between $100 and $300, depending on the specific tie rod end and alignment requirements. Factors to consider include the extent of wear, vehicle suspension design, and whether additional components, like control arms or steering linkage, require repairs. Proper alignment after replacement is critical to prevent uneven tire wear and maintain optimal steering performance.

Choosing the Right Component for Your Vehicle

Selecting the right component between a ball joint and a tie rod depends on your vehicle's suspension and steering system requirements. Ball joints provide pivotal movement for control arms, enhancing suspension flexibility and wheel alignment, while tie rods are critical for steering precision by transmitting force from the steering rack to the wheels. Evaluating wear patterns, vehicle make, and driving conditions ensures optimal safety and performance when choosing between these essential steering and suspension parts.

Ball joint Infographic

libterm.com

libterm.com