Annealing is a heat treatment process used to soften metal, improve its ductility, and relieve internal stresses. This technique enhances the material's workability, making it easier to shape and form without cracking. Discover how annealing can optimize your metalworking projects by reading the full article.

Table of Comparison

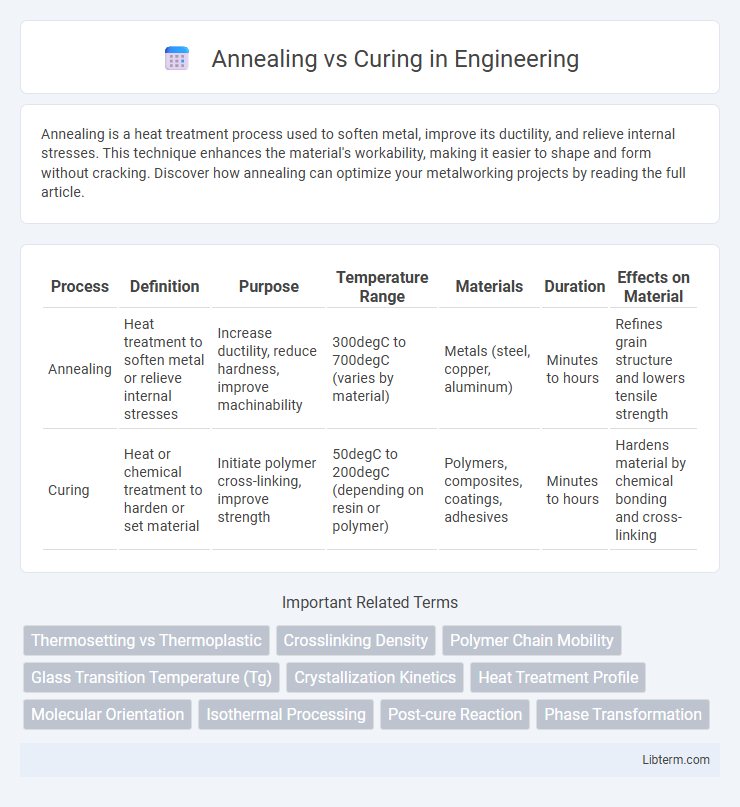

| Process | Definition | Purpose | Temperature Range | Materials | Duration | Effects on Material |

|---|---|---|---|---|---|---|

| Annealing | Heat treatment to soften metal or relieve internal stresses | Increase ductility, reduce hardness, improve machinability | 300degC to 700degC (varies by material) | Metals (steel, copper, aluminum) | Minutes to hours | Refines grain structure and lowers tensile strength |

| Curing | Heat or chemical treatment to harden or set material | Initiate polymer cross-linking, improve strength | 50degC to 200degC (depending on resin or polymer) | Polymers, composites, coatings, adhesives | Minutes to hours | Hardens material by chemical bonding and cross-linking |

Introduction to Annealing and Curing

Annealing is a heat treatment process used to soften metals, relieve internal stresses, and improve ductility by heating the material to a specific temperature and then slowly cooling it. Curing involves chemically or thermally hardening polymers, composites, or coatings by initiating a cross-linking reaction, typically at controlled temperatures. Both processes enhance material properties but target different structural changes and applications in manufacturing and material science.

Defining Annealing: Process and Purpose

Annealing is a controlled heating and cooling process used primarily to reduce internal stresses and improve the ductility of metals and glass. Typically conducted at temperatures below the material's melting point, annealing helps restore the material's microstructure by recrystallization, enhancing mechanical properties such as toughness and workability. This thermal treatment differs from curing, which generally involves chemical reactions to harden or set polymers and composites.

Understanding Curing: Methods and Applications

Curing involves chemical processes that harden or set materials such as polymers, adhesives, and coatings through heat, radiation, or chemical additives. Common curing methods include thermal curing, UV curing, and moisture curing, each offering specific advantages for enhancing mechanical properties and durability. Applications of curing range from industrial coatings and composites manufacturing to electronic encapsulation and adhesive bonding, ensuring improved strength, resistance, and longevity of the final product.

Key Differences Between Annealing and Curing

Annealing and curing are distinct thermal processes used to modify material properties, with annealing primarily aimed at reducing internal stresses and improving ductility in metals by heating and controlled cooling. Curing involves chemical reactions, often in polymers or composites, where heat or other agents initiate cross-linking to harden or set the material. The key differences lie in annealing's focus on relieving mechanical stresses and enhancing metal workability, whereas curing targets material strength and stability through chemical transformation.

Materials Commonly Subjected to Annealing

Materials commonly subjected to annealing include metals such as steel, copper, and aluminum alloys, as well as glass and certain polymers. Annealing involves heating these materials to a specific temperature and then slowly cooling them to remove internal stresses, improve ductility, and refine grain structure. This process enhances mechanical properties and prepares materials for further manufacturing steps, distinguishing it from curing, which primarily refers to hardening polymers and composites through chemical reactions.

Materials Frequently Cured in Industry

Annealing is primarily used for metals like steel and aluminum to reduce internal stresses and improve ductility, while curing is essential for polymers, composites, and adhesives to initiate chemical cross-linking for enhanced strength and durability. Industrial materials frequently cured include epoxy resins, silicones, and polyurethane coatings, which require specific temperature profiles and times for optimal mechanical properties. Both processes are critical in manufacturing but target different material types and transformations.

Industrial Applications: Annealing vs Curing

Annealing in industrial applications primarily involves controlled heating and slow cooling of metals or glass to reduce internal stresses, improve ductility, and enhance machinability, crucial for manufacturing processes like metal forming and glass production. Curing is essential in polymer and composite industries where chemical reactions, often heat-activated, solidify resins or adhesives to achieve desired mechanical properties and durability, such as in coatings, composites, and electronics encapsulation. The choice between annealing and curing depends on the material type and desired property enhancements, with annealing targeting metallic and glass stress relief, while curing focuses on chemical hardening of polymers.

Advantages and Disadvantages of Each Process

Annealing improves metal ductility and reduces internal stresses by slow cooling, enhancing machinability but requiring longer processing times and higher energy consumption. Curing strengthens polymers and composites through chemical reactions at controlled temperatures, offering faster hardening and improved mechanical properties but potentially causing brittleness and requiring precise temperature control. Both processes optimize material performance but differ in application specificity, with annealing suited for metals and curing tailored to thermoset resins and composites.

Choosing the Right Process: Critical Factors

Choosing the right process between annealing and curing depends on the material composition and the desired mechanical properties. Annealing is critical for metals and glass, enhancing ductility and reducing internal stresses through controlled heating and cooling cycles. Curing suits polymers and composites, where chemical reactions solidify materials, emphasizing parameters like temperature, time, and catalyst presence to achieve optimal hardness and durability.

Future Trends in Annealing and Curing Technologies

Future trends in annealing and curing technologies emphasize advanced automation and real-time process monitoring using AI and IoT integration to enhance precision and energy efficiency. Development of eco-friendly curing agents and annealing methods aims to reduce environmental impact while maintaining material performance. Innovations in rapid thermal processing and hybrid annealing-curing systems are expected to accelerate production cycles and improve product quality in industries like semiconductor manufacturing and composite materials.

Annealing Infographic

libterm.com

libterm.com