Sliding friction occurs when two surfaces move against each other, generating resistance that slows motion. This force depends on the materials in contact and the normal force pressing them together. Explore the article to understand how sliding friction affects everyday objects and how you can manage it effectively.

Table of Comparison

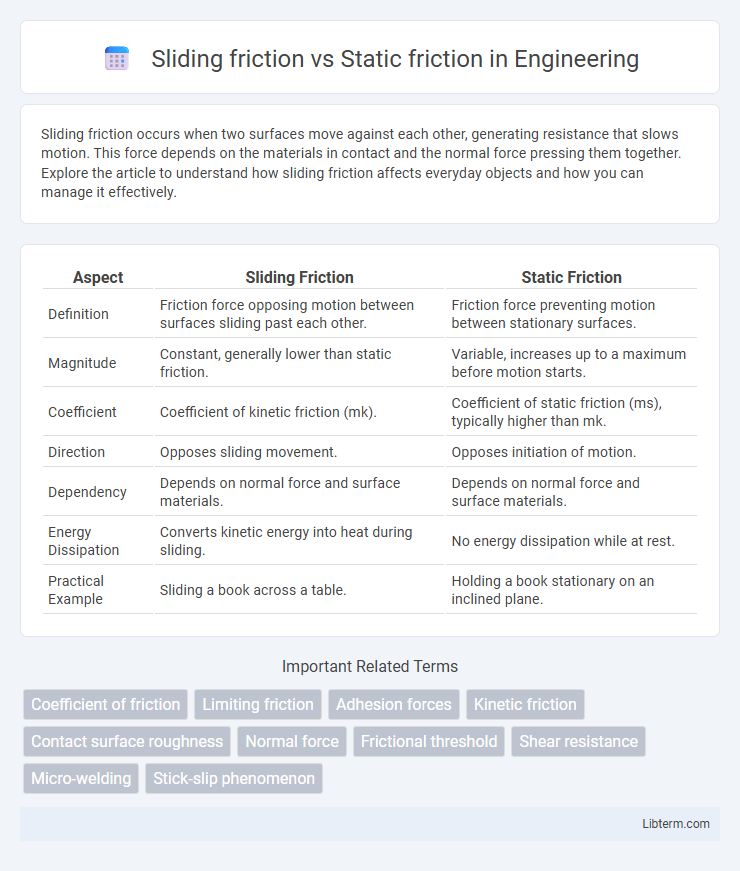

| Aspect | Sliding Friction | Static Friction |

|---|---|---|

| Definition | Friction force opposing motion between surfaces sliding past each other. | Friction force preventing motion between stationary surfaces. |

| Magnitude | Constant, generally lower than static friction. | Variable, increases up to a maximum before motion starts. |

| Coefficient | Coefficient of kinetic friction (mk). | Coefficient of static friction (ms), typically higher than mk. |

| Direction | Opposes sliding movement. | Opposes initiation of motion. |

| Dependency | Depends on normal force and surface materials. | Depends on normal force and surface materials. |

| Energy Dissipation | Converts kinetic energy into heat during sliding. | No energy dissipation while at rest. |

| Practical Example | Sliding a book across a table. | Holding a book stationary on an inclined plane. |

Introduction to Sliding and Static Friction

Sliding friction opposes the motion of two surfaces sliding past each other and is generally lower than static friction, which resists the initiation of motion between stationary surfaces. Static friction adjusts up to a maximum threshold, preventing movement until the applied force exceeds this limit, whereas sliding friction remains relatively constant once motion begins. Understanding the distinct characteristics of both types is crucial for analyzing forces in mechanics and designing systems involving contact surfaces.

What is Static Friction?

Static friction is the resistive force that prevents two surfaces from sliding past each other when at rest, acting up to a maximum limit determined by the normal force and the coefficient of static friction. It must be overcome for motion to start, making it generally higher than sliding friction, which acts once the surfaces are moving. This force plays a crucial role in everyday activities such as walking, driving, and object stability.

What is Sliding Friction?

Sliding friction is the resistive force that opposes the motion of two surfaces sliding past each other, occurring once an object is already in motion. It is generally lower than static friction, which is the force that must be overcome to initiate movement from rest. This type of friction depends on the nature of the surfaces in contact and the normal force pressing them together.

Key Differences Between Static and Sliding Friction

Static friction acts between two surfaces that are not moving relative to each other, preventing motion up to a certain threshold. Sliding friction occurs when one surface slides over another, opposing the relative motion with a generally constant force lower than the maximum static friction. The coefficient of static friction is typically higher than the coefficient of sliding friction, reflecting the greater force needed to initiate movement compared to maintaining it.

Factors Affecting Static Friction

Static friction depends on the nature of the surfaces in contact and the normal force pressing them together, with rougher surfaces and higher normal forces increasing frictional resistance. Microscopic irregularities and adhesion at the contact points create stronger bonds, requiring greater force to initiate motion compared to sliding friction. Surface contaminants like dust or lubricants can significantly reduce static friction by altering these contact interactions and reducing adhesion.

Factors Influencing Sliding Friction

Sliding friction depends on surface roughness, material types, and normal force between contacting surfaces. Temperature and presence of lubricants significantly reduce sliding friction by minimizing direct surface contact. Unlike static friction, sliding friction remains relatively constant as motion maintains continuous micro-asperity interactions.

Real-World Examples of Static Friction

Static friction enables objects like a parked car on an incline or a person standing still to resist movement by providing the necessary grip between surfaces. In construction, static friction keeps scaffolding stable against sliding, ensuring worker safety. The strength of static friction depends on the roughness of surfaces and the normal force pressing them together, preventing motion until an applied force exceeds the static friction limit.

Practical Applications of Sliding Friction

Sliding friction plays a crucial role in practical applications such as braking systems, where it helps slow down or stop moving vehicles by converting kinetic energy into heat. It is essential in conveyor belts and machinery, enabling controlled movement of materials and components by providing resistance to sliding motion. The efficiency and safety of tools like skis and ice skates depend on managing sliding friction to optimize glide and control on surfaces.

Measuring Static vs Sliding Friction

Measuring static friction involves gradually applying force to an object until it overcomes the initial resistance and starts to move, quantifying the maximum force before motion occurs. Sliding friction is measured by applying a constant force to keep the object moving at a steady velocity, determining the force needed to maintain motion. Precise measurement tools like force sensors or spring scales are essential for accurately comparing the static friction coefficient, which is typically higher, to the sliding friction coefficient.

Reducing and Controlling Friction in Everyday Life

Reducing sliding friction involves using lubricants like oil or grease to create a thin film between surfaces, minimizing direct contact and wear, which is essential in machinery and vehicle engines for smoother operation and energy efficiency. Controlling static friction can be achieved by selecting materials with appropriate surface textures or applying coatings that lower adhesion, important for preventing slips and improving safety in footwear and road surfaces. Understanding the differences between sliding and static friction helps optimize design choices in everyday tools and devices, enhancing performance and durability.

Sliding friction Infographic

libterm.com

libterm.com