HAZOP is a systematic method used to identify and evaluate potential hazards and operability problems in industrial processes to enhance safety and reliability. It involves a detailed examination of process deviations and their causes, ensuring that all possible risks are addressed before implementation. Discover how applying HAZOP principles can safeguard Your operations by reading the full article.

Table of Comparison

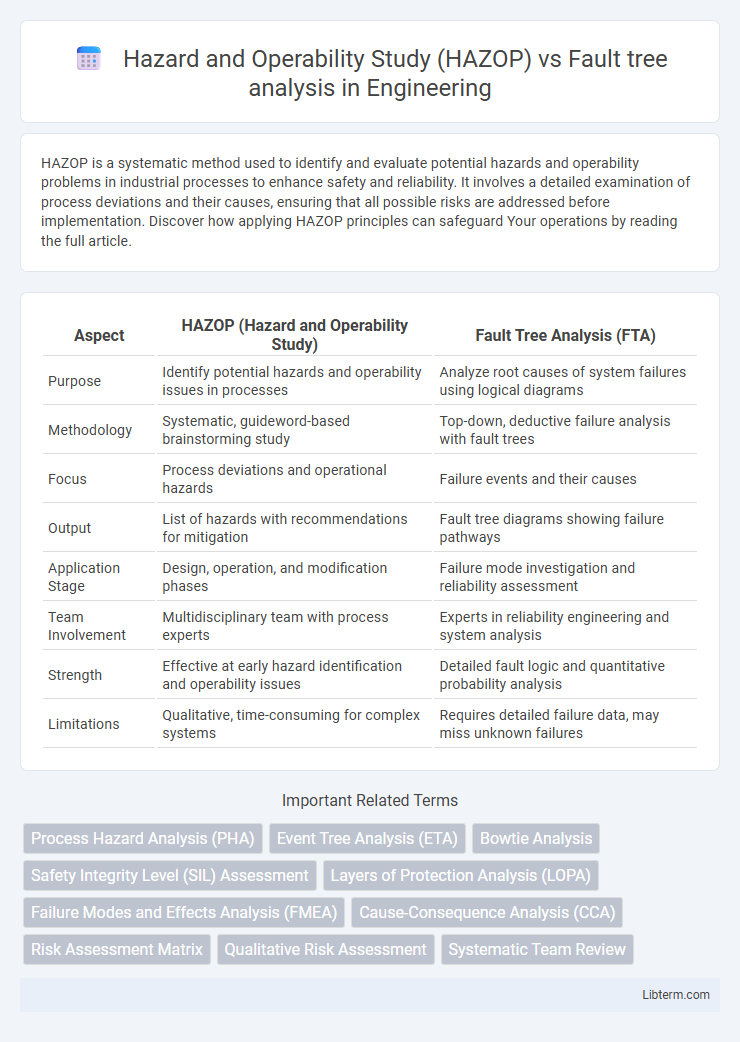

| Aspect | HAZOP (Hazard and Operability Study) | Fault Tree Analysis (FTA) |

|---|---|---|

| Purpose | Identify potential hazards and operability issues in processes | Analyze root causes of system failures using logical diagrams |

| Methodology | Systematic, guideword-based brainstorming study | Top-down, deductive failure analysis with fault trees |

| Focus | Process deviations and operational hazards | Failure events and their causes |

| Output | List of hazards with recommendations for mitigation | Fault tree diagrams showing failure pathways |

| Application Stage | Design, operation, and modification phases | Failure mode investigation and reliability assessment |

| Team Involvement | Multidisciplinary team with process experts | Experts in reliability engineering and system analysis |

| Strength | Effective at early hazard identification and operability issues | Detailed fault logic and quantitative probability analysis |

| Limitations | Qualitative, time-consuming for complex systems | Requires detailed failure data, may miss unknown failures |

Introduction to HAZOP and Fault Tree Analysis

Hazard and Operability Study (HAZOP) systematically identifies potential hazards and operability problems by examining deviations from design intentions using guide words in process industries. Fault Tree Analysis (FTA) deductively analyzes the root causes of system failures by constructing a top-down logic diagram that visualizes failure pathways and their probabilities. Both HAZOP and FTA are essential risk assessment tools providing structured methodologies to improve safety and reliability in complex engineering systems.

Understanding the Objectives of HAZOP

Hazard and Operability Study (HAZOP) primarily aims to identify potential hazards and operational issues within industrial processes by systematically examining deviations from design intent. It emphasizes understanding process conditions that could lead to safety risks or inefficiencies, enabling proactive risk management. Unlike Fault Tree Analysis, which focuses on failure logic and probabilistic assessment, HAZOP centers on detailed, qualitative analysis of process deviations to improve safety and operability.

Key Principles of Fault Tree Analysis

Fault Tree Analysis (FTA) systematically identifies potential causes of system failures by using Boolean logic to combine various fault events into a structured diagram. It emphasizes top-down analysis, starting from the undesired event and tracing back to root causes, enabling quantification of failure probabilities. Unlike HAZOP's qualitative brainstorming approach, FTA provides probabilistic risk assessment critical for decision-making in safety-critical industries.

Methodology: HAZOP Step-by-Step Process

The Hazard and Operability Study (HAZOP) methodology involves a structured and systematic step-by-step process including preparation, defining nodes, selecting guide words, and performing detailed examinations of deviations to identify potential hazards and operability problems. Each node within the process is analyzed by applying guide words such as "No," "More," "Less," and "As well as" to stimulate discussion on possible deviations from design intent. This iterative approach ensures comprehensive hazard identification by involving multidisciplinary teams to evaluate causes, consequences, safeguards, and recommendations for each analyzed deviation.

Methodology: Fault Tree Analysis Workflow

Fault Tree Analysis (FTA) involves a top-down, deductive methodology that starts with a predefined undesired event, systematically identifying all possible causes through logical gates such as AND and OR. The workflow includes defining the top event, constructing the fault tree by decomposing events into basic causes, performing qualitative analysis to find minimal cut sets, and conducting quantitative analysis to estimate failure probabilities. This method contrasts with HAZOP's approach, as FTA emphasizes causal relationships and probability calculations within complex systems for risk assessment.

Comparative Table: HAZOP vs Fault Tree Analysis

Hazard and Operability Study (HAZOP) systematically identifies potential hazards by examining deviations in process parameters, making it highly qualitative and process-focused. Fault Tree Analysis (FTA) uses a top-down, deductive approach to quantify the probability of system failures through logical gate modeling, emphasizing failure pathways. The comparative table highlights HAZOP's strength in discovering design and operability issues early in complex chemical processes, while FTA excels in reliability assessment and failure probability quantification within safety-critical systems.

Strengths and Limitations of HAZOP

Hazard and Operability Study (HAZOP) excels in systematically identifying potential hazards and operational issues through structured brainstorming and guide word techniques, making it highly effective for complex chemical and process industries. Its strengths include thorough exploration of deviations from design intentions and fostering multidisciplinary team collaboration, but it can be time-consuming and relies heavily on expert judgment, which may introduce subjectivity. Limitations of HAZOP involve challenges in quantifying risk levels and difficulty in addressing interactions between failures, areas where Fault Tree Analysis (FTA) provides more quantitative, top-down failure cause analysis.

Strengths and Limitations of Fault Tree Analysis

Fault Tree Analysis (FTA) excels in systematically identifying the root causes of system failures through a top-down, deductive approach, making it highly effective for complex systems with well-defined failure modes. Its strength lies in quantifying failure probabilities and visualizing fault relationships, which aids risk assessment and decision-making. Limitations include difficulty handling human errors and dynamic conditions, potential complexity explosion in large systems, and reliance on accurate failure data, which can constrain its applicability compared to the more qualitative and flexible Hazard and Operability Study (HAZOP).

Best Applications: When to Use HAZOP or Fault Tree Analysis

Hazard and Operability Study (HAZOP) is best applied during the design and early operation phases of complex process systems to identify potential deviations and hazards systematically. Fault Tree Analysis (FTA) excels in failure analysis and reliability assessments by tracing the root causes of specific undesirable events or system failures. Use HAZOP for detailed hazard identification in process industries and FTA for quantifying failure probabilities and supporting risk management decisions.

Integrating HAZOP and Fault Tree Analysis in Risk Management

Integrating Hazard and Operability Study (HAZOP) with Fault Tree Analysis (FTA) enhances risk management by combining HAZOP's systematic identification of process deviations with FTA's logical fault propagation to pinpoint root causes of hazards. This integration enables comprehensive hazard identification and quantification of failure probabilities, improving the accuracy of risk assessments and decision-making processes. Leveraging both methodologies ensures robust safety management, reduces operational risks, and supports compliance with industry safety standards.

Hazard and Operability Study (HAZOP) Infographic

libterm.com

libterm.com