Slot welds provide a strong and reliable method for joining metal components by filling pre-cut slots with weld material, ensuring firm attachment and structural integrity. This technique is widely used in automotive and construction industries to enhance durability while minimizing distortion. Explore the detailed benefits and applications of slot welds in the rest of the article to improve your welding knowledge.

Table of Comparison

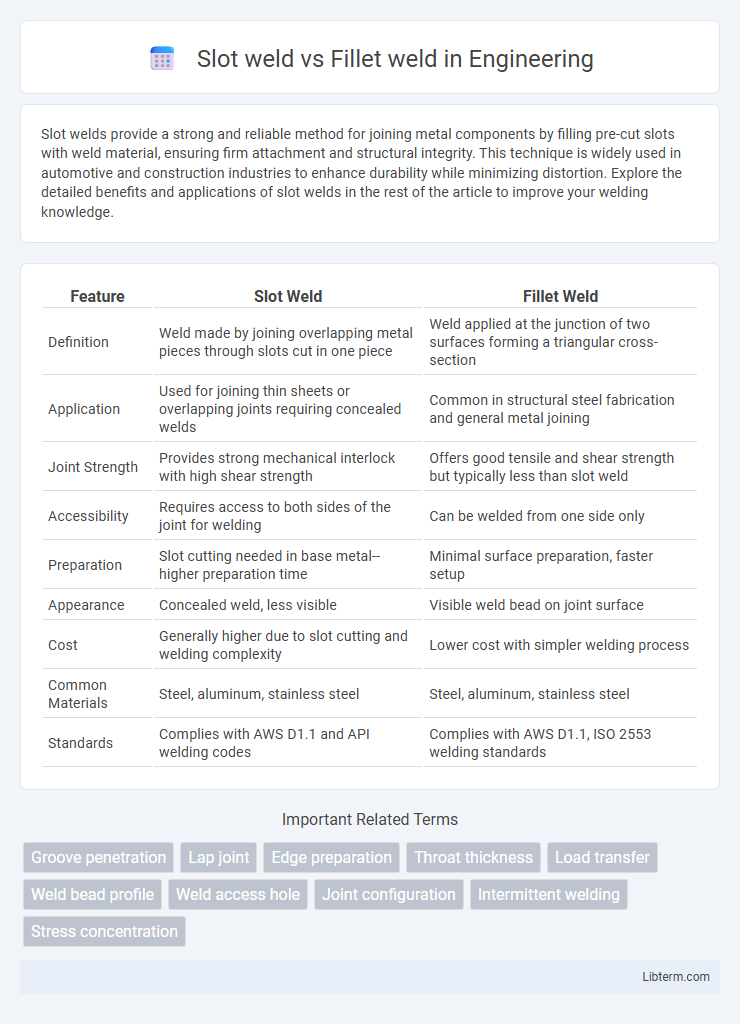

| Feature | Slot Weld | Fillet Weld |

|---|---|---|

| Definition | Weld made by joining overlapping metal pieces through slots cut in one piece | Weld applied at the junction of two surfaces forming a triangular cross-section |

| Application | Used for joining thin sheets or overlapping joints requiring concealed welds | Common in structural steel fabrication and general metal joining |

| Joint Strength | Provides strong mechanical interlock with high shear strength | Offers good tensile and shear strength but typically less than slot weld |

| Accessibility | Requires access to both sides of the joint for welding | Can be welded from one side only |

| Preparation | Slot cutting needed in base metal--higher preparation time | Minimal surface preparation, faster setup |

| Appearance | Concealed weld, less visible | Visible weld bead on joint surface |

| Cost | Generally higher due to slot cutting and welding complexity | Lower cost with simpler welding process |

| Common Materials | Steel, aluminum, stainless steel | Steel, aluminum, stainless steel |

| Standards | Complies with AWS D1.1 and API welding codes | Complies with AWS D1.1, ISO 2553 welding standards |

Introduction to Slot Welds and Fillet Welds

Slot welds involve filling a circular or elongated hole in one metal piece with weld metal to join it to an overlapping piece, providing strong, localized connections often used in structural applications. Fillet welds create a triangular cross-section at the joint between two surfaces, typically joining perpendicular or angled metals, widely used for general fabrication due to their ease and versatility. Both weld types are essential in construction and manufacturing, with slot welds preferred for hidden joints and fillet welds for visible, external seams.

Definitions: What Are Slot Welds and Fillet Welds?

Slot welds are welds made by filling a slot or hole in one metal piece to join it to another metal underneath, providing a strong, concealed joint often used for overlapping surfaces. Fillet welds are triangular cross-section welds applied at the junction of two metal parts, typically at right angles, creating a smooth, visible fillet to reinforce the joint. Both welding types serve distinct structural functions, with slot welds emphasizing hidden attachment and fillet welds focusing on surface joint strength.

Design and Geometry Differences

Slot welds are created by welding within a pre-cut slot or hole in one metal piece that overlaps another, providing resistance against shear forces through the mechanical interlocking of the weld nugget and base materials. Fillet welds, typically triangular in cross-section, are applied to the outside corner or lap of two metal surfaces, relying on fusion across the joint edges without material removal. The design of slot welds requires precise slot dimensions and fit-up to ensure proper weld size and strength, whereas fillet welds allow for more flexibility in weld size and are commonly used for joining perpendicular or overlapping components.

Applications of Slot Welds

Slot welds are primarily used in applications requiring the joining of overlapping metal components where access is limited to one side, such as in automotive and aircraft assembly. These welds provide strong, efficient joints by filling pre-cut slots or holes with weld metal, making them ideal for attaching sheets or components to structural supports. Slot welds excel in scenarios demanding precise control over weld size and penetration, enhancing joint integrity without extensive surface preparation.

Common Uses of Fillet Welds

Fillet welds are widely used in structural steel fabrication, shipbuilding, and automotive industries due to their versatility in joining perpendicular or overlapping metal surfaces. They provide strong, reliable connections for T-joints, lap joints, and corner joints, making them ideal for load-bearing applications. Common fillet weld configurations include single and double fillets, which accommodate various thicknesses and stress requirements in fabrication projects.

Strength and Load Distribution Comparison

Slot welds offer localized strength by connecting overlapping parts through a cutout filled with weld material, resulting in concentrated load resistance primarily around the slot edges. Fillet welds provide continuous, triangular cross-sectional connections along joint interfaces, enabling more uniform load distribution and higher overall strength in shear and tension compared to slot welds. In structural applications, fillet welds are preferred for their superior ability to distribute stresses and accommodate dynamic loads, whereas slot welds are suited for smaller, less critical connections.

Welding Techniques for Slot and Fillet Welds

Slot welds require precise alignment of the edges and a clean slot opening to ensure full penetration and strong bonding, typically achieved through tack welding before final welding passes. Fillet welds involve depositing weld metal in the corner formed by two joined surfaces at approximately right angles, using stringer or weave bead techniques to control heat input and weld shape. Technique selection depends on joint design, accessibility, and load requirements, with slot welds offering better fatigue resistance and fillet welds providing versatility in various structural applications.

Cost and Efficiency Considerations

Slot welds generally incur higher labor costs due to the precise hole preparation and fitting required, impacting overall project expenses. Fillet welds are more cost-effective and faster to execute, offering greater efficiency in mass production and field applications. Choosing between slot weld and fillet weld depends on balancing structural requirements with budget constraints and fabrication speed.

Code and Standard Compliance

Slot welds and fillet welds must comply with specific codes such as AWS D1.1 for structural steel, which outlines their acceptable applications and dimensional requirements. Slot welds require strict adherence to size limits and spacing as detailed in clause 22.4, ensuring proper load transfer and avoiding weld discontinuities. Fillet welds follow standards on throat thickness and leg size per AWS D1.1 Table 3.3, guaranteeing strength and quality in joint designs.

Choosing the Right Weld for Your Project

Selecting the right weld for your project hinges on the specific load requirements and joint design. Slot welds provide strong, hidden connections ideal for attaching plates to another surface with minimal distortion. Fillet welds are versatile and simple to apply, making them suitable for joining two perpendicular or angled surfaces exposed to shear and tensile stresses.

Slot weld Infographic

libterm.com

libterm.com