Riveting designs captivate your attention by combining striking visuals with compelling storytelling. These elements create an immersive experience that keeps you engaged from start to finish. Explore the article to discover how riveting content can transform your projects.

Table of Comparison

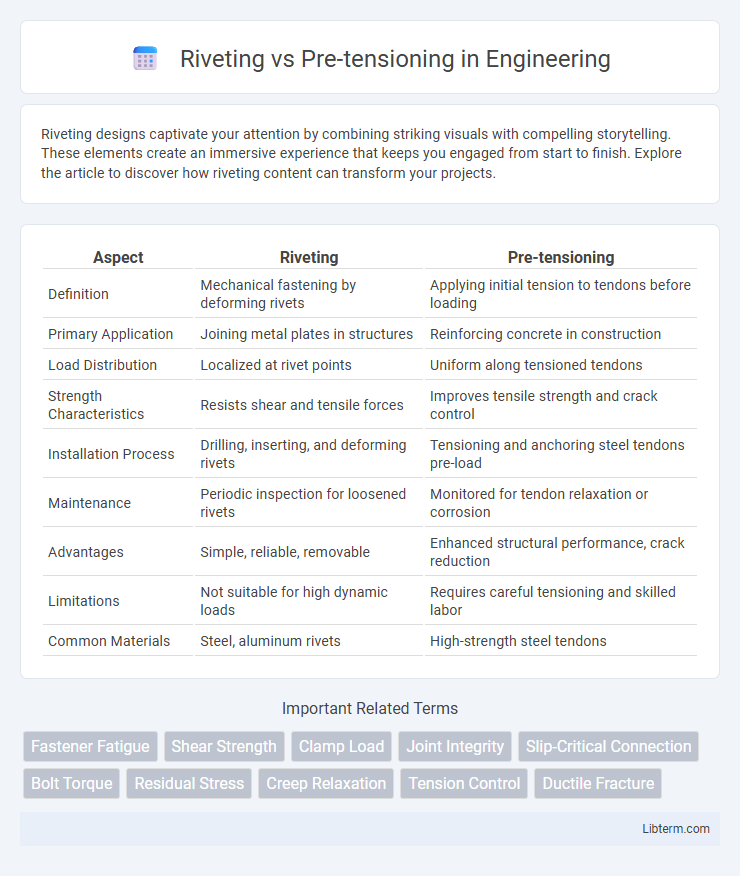

| Aspect | Riveting | Pre-tensioning |

|---|---|---|

| Definition | Mechanical fastening by deforming rivets | Applying initial tension to tendons before loading |

| Primary Application | Joining metal plates in structures | Reinforcing concrete in construction |

| Load Distribution | Localized at rivet points | Uniform along tensioned tendons |

| Strength Characteristics | Resists shear and tensile forces | Improves tensile strength and crack control |

| Installation Process | Drilling, inserting, and deforming rivets | Tensioning and anchoring steel tendons pre-load |

| Maintenance | Periodic inspection for loosened rivets | Monitored for tendon relaxation or corrosion |

| Advantages | Simple, reliable, removable | Enhanced structural performance, crack reduction |

| Limitations | Not suitable for high dynamic loads | Requires careful tensioning and skilled labor |

| Common Materials | Steel, aluminum rivets | High-strength steel tendons |

Introduction to Riveting and Pre-tensioning

Riveting involves mechanically joining materials by inserting and deforming rivets to create a strong, permanent bond commonly used in construction and manufacturing. Pre-tensioning applies tension to steel tendons before concrete casting to enhance structural performance, improving load-bearing capacity and reducing cracking. Both methods serve critical roles in structural engineering, with riveting suited for metal assembly and pre-tensioning optimized for reinforced concrete elements.

Understanding Riveting: Definition and Process

Riveting is a mechanical fastening process that involves joining two or more materials by inserting a metal pin called a rivet through pre-drilled holes and deforming its tail to create a permanent joint. This process provides high shear strength and is widely used in structural applications such as aircraft and bridges. Unlike pre-tensioning, which applies tension to structural elements before load application, riveting relies on mechanical deformation to secure components without inducing initial stress.

Pre-tensioning Explained: Methods and Applications

Pre-tensioning involves applying tension to steel tendons before concrete is cast, enhancing structural strength and controlling cracking in concrete elements. Common methods include pre-tensioning bed systems where steel wires are stretched and anchored prior to concrete placement, ensuring improved load distribution and durability. This technique is widely used in precast beams, slabs, and bridge components, optimizing performance in infrastructure and commercial construction projects.

Key Differences Between Riveting and Pre-tensioning

Riveting involves joining two or more metal pieces by inserting and deforming a metal pin or rivet through aligned holes, creating a permanent mechanical bond primarily used in structural applications. Pre-tensioning, commonly applied in prestressed concrete, involves tensioning steel tendons before the concrete is cast, enhancing tensile strength and minimizing cracking by introducing compressive stress. The key differences lie in rivet's role as a fastening method forming a mechanical lock, while pre-tensioning is a stress-inducing process designed to improve load-bearing capacity and structural integrity.

Material Requirements for Riveting vs Pre-tensioning

Riveting requires materials with adequate ductility and toughness to withstand deformation during installation without cracking, typically favoring softer metals such as aluminum or mild steel. Pre-tensioning demands high-strength, low-relaxation materials, often utilizing high-grade steel cables or rods capable of sustaining significant tensile loads over time. The selection of materials directly impacts the structural integrity and durability, with riveting materials needing plastic deformation properties and pre-tensioning materials requiring superior tensile strength and fatigue resistance.

Structural Performance: Strength and Durability Comparison

Riveting provides strong mechanical fastening with good shear strength but may be prone to loosening under dynamic loads, affecting long-term durability. Pre-tensioning enhances structural performance by applying a high initial tensile force, improving load distribution and increasing resistance to fatigue and stress corrosion. Structures using pre-tensioned elements generally exhibit superior strength and durability due to controlled tension and improved joint stiffness.

Cost and Efficiency in Construction Projects

Riveting offers lower initial material costs but involves higher labor expenses and longer installation times compared to pre-tensioning. Pre-tensioning enhances efficiency by reducing onsite assembly time and providing greater structural strength, leading to lower lifecycle costs despite higher upfront investment. Construction projects benefit from pre-tensioning through improved load distribution and minimized maintenance, resulting in overall cost savings and faster completion.

Advantages and Disadvantages of Riveting

Riveting provides strong, permanent joints ideal for high-stress applications and materials that cannot be welded, ensuring durability without heat distortion. Its disadvantages include longer installation times and the need for access to both sides of the assembly, limiting use in complex or confined spaces. Riveting also requires skilled labor and can add weight compared to modern fastening methods like pre-tensioning bolts.

Pros and Cons of Pre-tensioning

Pre-tensioning in construction offers enhanced structural efficiency by applying tension to steel tendons before concrete casting, resulting in improved load-bearing capacity and reduced cracking. This method accelerates the curing process and enables precise control over prestress levels, but it requires specialized equipment and higher initial costs compared to riveting. Pre-tensioning is less suitable for on-site adjustments and complex joint configurations where riveting allows easier assembly and flexible modifications.

Choosing the Right Technique: Factors to Consider

Choosing between riveting and pre-tensioning hinges on factors such as load requirements, material compatibility, and installation environment. Riveting excels in applications demanding strong, permanent joints with resistance to shear forces, often favored in aerospace and automotive industries. Pre-tensioning suits scenarios requiring controlled clamping forces and minimal joint movement, commonly used in structural engineering and heavy machinery assembly.

Riveting Infographic

libterm.com

libterm.com