A screw pair is a fundamental mechanical component consisting of a threaded screw and a matching nut, designed to convert rotational motion into linear motion with high precision. It plays a crucial role in machines requiring accurate positioning and load transfer, often found in applications such as lead screws in CNC machinery and jackscrews in lifting mechanisms. Explore the rest of the article to understand how screw pairs enhance your equipment's performance and reliability.

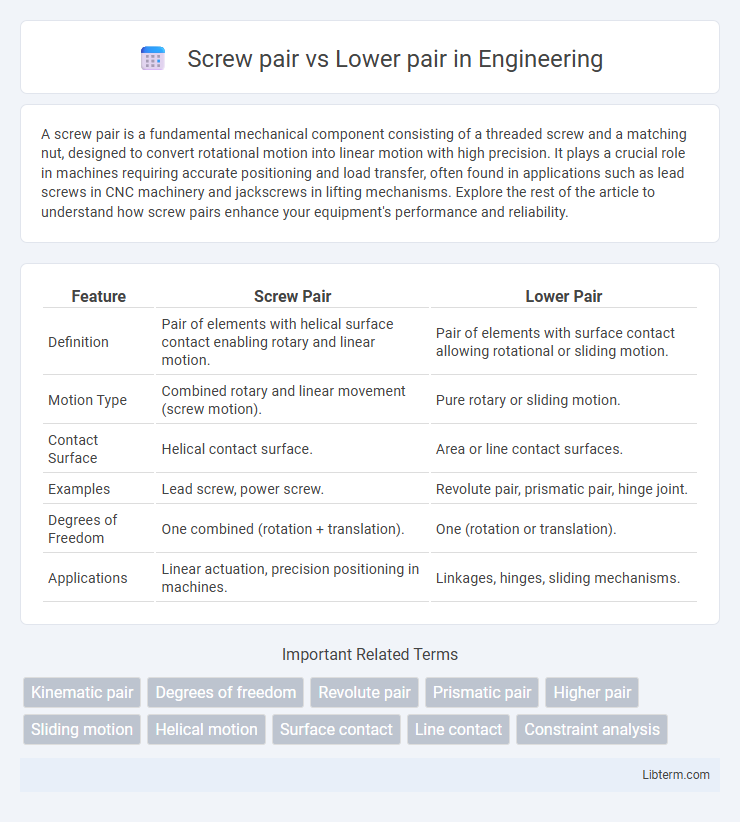

Table of Comparison

| Feature | Screw Pair | Lower Pair |

|---|---|---|

| Definition | Pair of elements with helical surface contact enabling rotary and linear motion. | Pair of elements with surface contact allowing rotational or sliding motion. |

| Motion Type | Combined rotary and linear movement (screw motion). | Pure rotary or sliding motion. |

| Contact Surface | Helical contact surface. | Area or line contact surfaces. |

| Examples | Lead screw, power screw. | Revolute pair, prismatic pair, hinge joint. |

| Degrees of Freedom | One combined (rotation + translation). | One (rotation or translation). |

| Applications | Linear actuation, precision positioning in machines. | Linkages, hinges, sliding mechanisms. |

Introduction to Kinematic Pairs

Kinematic pairs describe the connections between two mechanical elements allowing relative motion, classified into lower pairs and higher pairs. Screw pairs, a type of lower pair, provide helical motion by combining rotational and translational movements through threaded surfaces in contact. Lower pairs maintain surface contact with constrained motion, whereas screw pairs specifically enable precise motion transmission in mechanisms like lead screws and jackscrews.

Overview of Lower Pairs

Lower pairs are mechanical connections characterized by surface contact between elements, enabling constrained relative motion such as sliding or rolling, commonly found in hinges, sliders, and cam mechanisms. These pairs include revolute pairs (pin joints), prismatic pairs (sliding joints), and screw pairs, where the motion is constrained to one degree of freedom. In contrast, screw pairs combine rotational and translational motion through helical surfaces, distinguishing them within the broader classification of lower pairs.

What is a Screw Pair?

A screw pair is a type of kinematic pair where the relative motion between two elements combines rotation and translation along the same axis, resembling the motion of a screw. This mechanical linkage transforms rotational motion into linear displacement through the interaction of threads on a screw and a nut. Unlike lower pairs, which involve only one type of relative motion (either pure rotation or pure translation), screw pairs enable complex motion essential in precision mechanisms such as lead screws in machine tools.

Key Characteristics of Lower Pairs

Lower pairs are mechanical pairs characterized by surface contact between elements, allowing relative motion constrained to one or more degrees of freedom. Key characteristics include pure rolling or sliding contact, presence of kinematic constraints, and high precision in motion transfer, which reduce wear and increase durability. Unlike screw pairs that involve helical motion and mating threads, lower pairs mainly ensure rotational or translational motion through tight surface engagement.

Essential Features of Screw Pairs

Screw pairs are characterized by their helical motion, combining rotational and translational movements between two elements, which enables precise linear displacement through rotational input. Essential features include the presence of threaded surfaces, higher friction compared to lower pairs, and non-reversible motion ideal for locking mechanisms. Unlike lower pairs that rely mostly on simple motion pairs such as revolute or prismatic joints, screw pairs provide controlled motion transfer and load-bearing capacity in mechanical assemblies.

Comparative Analysis: Screw Pair vs Lower Pair

A screw pair is a mechanical linkage characterized by coupled rotational and translational motion through helical threads, enabling precise linear displacement with rotational input, whereas a lower pair involves surface contact between elements with relative motion limited to pure rotation or sliding. Screw pairs provide high accuracy and self-locking capabilities in mechanisms like jackscrews and lead screws, contrasting with lower pairs such as revolute or prismatic joints, which prioritize smoother rotation or sliding with less inherent positional stability. The comparative analysis highlights that screw pairs excel in applications requiring controlled motion transmission and load holding, while lower pairs offer versatility and simplicity in kinematic chains with lower friction and wear considerations.

Applications of Lower Pairs in Engineering

Lower pairs, characterized by surface contact between their elements, play a crucial role in engineering applications such as hinges, sliders, and cam mechanisms, enabling smooth and precise motion control. Compared to screw pairs, which convert rotational motion into linear motion through threaded engagement, lower pairs provide diverse kinematic connections essential for designing linkages in machinery like engines and robotic arms. Their applications enhance mechanical efficiency and reliability in systems requiring continuous and constrained relative motion.

Practical Uses of Screw Pairs

Screw pairs convert rotational motion into linear motion, making them essential in lead screws, jacks, and presses where precise movement and high load capacity are required. Lower pairs, characterized by surface contact like revolute or prismatic joints, are common in mechanisms demanding smooth rotational or sliding motion. Practical use of screw pairs includes CNC machines and micrometer adjustments, where controlled linear displacement is critical.

Advantages and Limitations: Screw Pair vs Lower Pair

Screw pairs provide high mechanical advantage and precise motion control due to their helical thread design, making them ideal for applications requiring accurate linear displacement and load transmission. However, they generally exhibit higher friction and slower motion compared to lower pairs, which consist of surface contacts like hinges and sliders that offer smoother, faster movement with reduced wear. Despite lower pairs enabling greater speed and efficiency in mechanisms such as gears and cams, they may lack the load-bearing capacity and positional accuracy inherent to screw pairs.

Conclusion: Choosing the Right Kinematic Pair

Selecting the appropriate kinematic pair depends on application requirements such as motion type, load capacity, and precision. Screw pairs offer precise linear motion with high load transmission, ideal for mechanisms requiring controlled translation and rotation. Lower pairs allow relative motion with surface contact, providing versatility for various mechanical linkages and ensuring smoother rotational or sliding movements.

Screw pair Infographic

libterm.com

libterm.com