Plug flow assumes a uniform velocity profile across the pipe, minimizing mixing and maintaining the fluid's original composition throughout the flow path. Turbulent flow, characterized by chaotic fluid motion and intense mixing, enhances heat and mass transfer but can lead to increased pressure drops. Understand the distinctions between plug flow and turbulent flow to optimize your design and process efficiency by reading further.

Table of Comparison

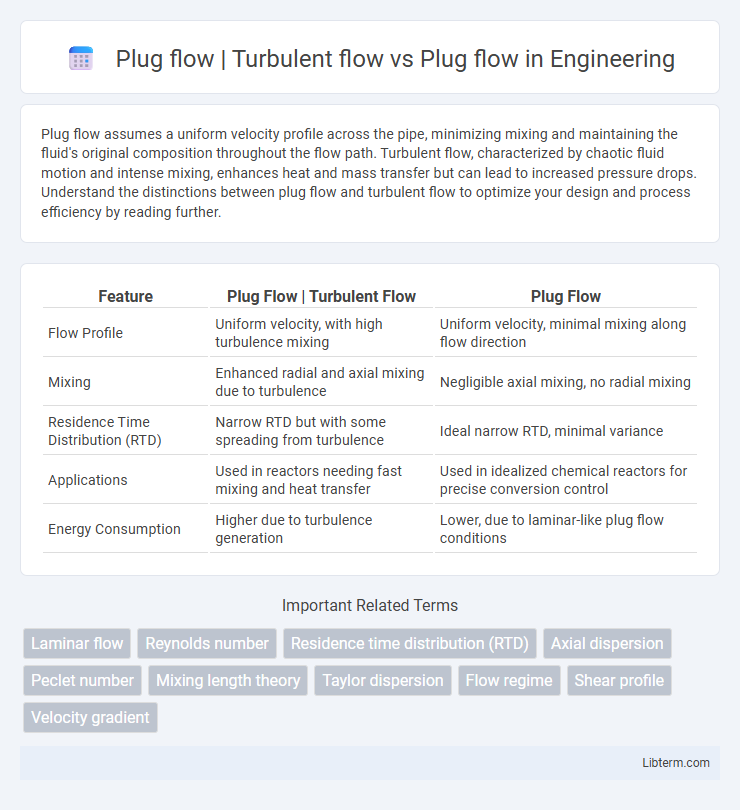

| Feature | Plug Flow | Turbulent Flow | Plug Flow |

|---|---|---|

| Flow Profile | Uniform velocity, with high turbulence mixing | Uniform velocity, minimal mixing along flow direction |

| Mixing | Enhanced radial and axial mixing due to turbulence | Negligible axial mixing, no radial mixing |

| Residence Time Distribution (RTD) | Narrow RTD but with some spreading from turbulence | Ideal narrow RTD, minimal variance |

| Applications | Used in reactors needing fast mixing and heat transfer | Used in idealized chemical reactors for precise conversion control |

| Energy Consumption | Higher due to turbulence generation | Lower, due to laminar-like plug flow conditions |

Introduction to Fluid Flow Regimes

Plug flow represents an ideal fluid flow regime where fluid particles move in parallel layers with uniform velocity, minimizing mixing along the flow direction. Turbulent flow features chaotic fluid motion with eddies and vortices causing intense mixing and fluctuating velocities across the flow cross-section. Understanding these flow regimes is essential for optimizing engineering processes such as chemical reactors, pipelines, and heat exchangers where fluid behavior impacts efficiency and performance.

What is Plug Flow?

Plug flow refers to a fluid flow regime where all fluid particles move with uniform velocity in parallel layers, minimizing mixing across the flow direction. Unlike turbulent flow, which is characterized by chaotic fluid motion and enhanced mixing, plug flow maintains a consistent velocity profile and little to no radial velocity gradient. This behavior is critical in chemical reactors, such as plug flow reactors (PFRs), where it ensures predictable residence time distribution and efficient reaction control.

Characteristics of Plug Flow

Plug flow is characterized by a uniform velocity profile across the pipe cross-section, with minimal axial mixing and particles moving in parallel layers at the same speed. Unlike turbulent flow, which exhibits chaotic velocity fluctuations and enhanced mixing, plug flow maintains a consistent flow front, leading to predictable residence times and efficient mass transfer in reactors. This flow regime is ideal for processes requiring precise control of reaction time and uniform exposure, such as in chemical reactors and tubular systems.

Understanding Turbulent Flow

Turbulent flow is characterized by chaotic fluid motion with irregular fluctuations, resulting in enhanced mixing and momentum transfer, unlike the uniform velocity profile seen in plug flow. Understanding turbulent flow involves analyzing Reynolds number, which indicates whether the flow regime is laminar or turbulent, typically exceeding 4000 for turbulence. Engineers optimize reactor designs by considering turbulent flow to improve mass and heat transfer rates, crucial for efficient chemical processing.

Key Differences Between Turbulent Flow and Plug Flow

Plug flow is characterized by a uniform velocity profile across the cross-section of a pipe, resulting in minimal mixing between fluid layers, whereas turbulent flow exhibits chaotic, irregular fluctuations with significant mixing and velocity variation. Key differences include the Reynolds number threshold, with plug flow occurring at low Reynolds numbers indicating laminar conditions and turbulent flow appearing at high Reynolds numbers above approximately 4000. Energy losses tend to be lower in plug flow due to streamlined movement, while turbulent flow causes increased friction and pressure drop because of eddies and vortices.

Advantages of Plug Flow in Industrial Processes

Plug flow reactors ensure uniform residence time for reactants, enhancing product consistency and yield in industrial processes. The absence of back-mixing in plug flow minimizes side reactions and improves conversion efficiency compared to turbulent flow systems. This controlled flow characteristic is advantageous for precise reaction control, scaling, and energy optimization in chemical manufacturing.

Limitations of Plug Flow Reactors

Plug flow reactors (PFRs) assume idealized laminar flow with no axial mixing, which limits their effectiveness in processes requiring uniform residence time and thorough mixing. In contrast, turbulent flow enhances mixing and mass transfer, reducing concentration gradients that PFRs cannot address. The primary limitation of plug flow reactors is their inability to handle reactions sensitive to flow maldistribution or requiring instantaneous mixing, leading to potential hot spots and reduced conversion efficiency.

Applications of Turbulent Flow and Plug Flow

Turbulent flow, characterized by chaotic fluid motion, is essential in industrial mixing, chemical reactors, and heat exchangers where enhanced mass and heat transfer rates improve reaction efficiency and uniformity. Plug flow, exhibiting a uniform velocity profile with minimal mixing along the flow path, is crucial in processes like tubular reactors and microfluidic devices that require precise residence time control and predictable flow behavior. Both flow regimes optimize system performance by balancing mixing intensity and flow uniformity to meet specific engineering and process goals.

Flow Profile Analysis: Plug Flow vs. Turbulent Flow

Plug flow exhibits a uniform velocity profile with minimal radial velocity gradients, ensuring that all fluid particles move at nearly the same speed along the flow direction, which minimizes axial mixing and maximizes reaction efficiency. Turbulent flow displays a highly irregular velocity profile with rapid fluctuations and mixing caused by eddies and vortices, enhancing mass and heat transfer but increasing axial dispersion. Flow profile analysis reveals that plug flow is ideal for processes requiring predictable residence time distribution, whereas turbulent flow suits applications needing superior mixing and homogenization.

Choosing the Right Flow Regime for Process Optimization

Plug flow ensures uniform residence time and minimal back-mixing, ideal for processes requiring precise reaction control and consistent product quality. Turbulent flow enhances mixing and heat transfer rates, beneficial for processes needing rapid homogenization and temperature uniformity. Selecting the right flow regime depends on process goals, reactor design, and desired mass transfer characteristics to optimize efficiency and product yield.

Plug flow | Turbulent flow Infographic

libterm.com

libterm.com