Machining is a precise manufacturing process that shapes materials by removing unwanted parts using tools like lathes, mills, and drills. This technique enhances product accuracy and surface finish, making it essential for industries such as aerospace, automotive, and electronics. Discover how mastering machining can improve your production efficiency by exploring the rest of the article.

Table of Comparison

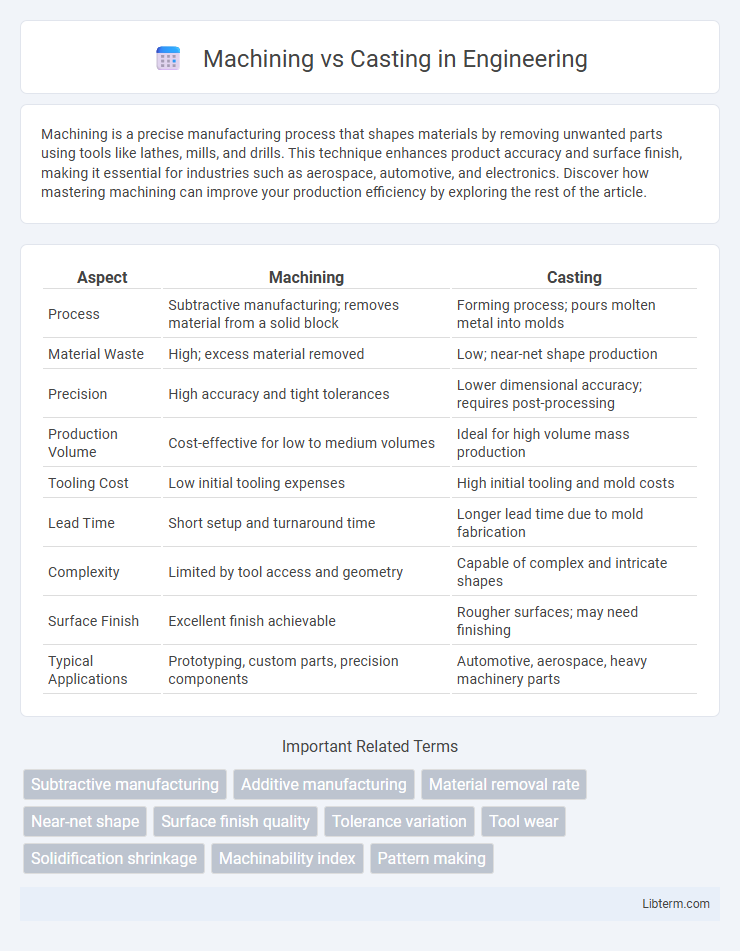

| Aspect | Machining | Casting |

|---|---|---|

| Process | Subtractive manufacturing; removes material from a solid block | Forming process; pours molten metal into molds |

| Material Waste | High; excess material removed | Low; near-net shape production |

| Precision | High accuracy and tight tolerances | Lower dimensional accuracy; requires post-processing |

| Production Volume | Cost-effective for low to medium volumes | Ideal for high volume mass production |

| Tooling Cost | Low initial tooling expenses | High initial tooling and mold costs |

| Lead Time | Short setup and turnaround time | Longer lead time due to mold fabrication |

| Complexity | Limited by tool access and geometry | Capable of complex and intricate shapes |

| Surface Finish | Excellent finish achievable | Rougher surfaces; may need finishing |

| Typical Applications | Prototyping, custom parts, precision components | Automotive, aerospace, heavy machinery parts |

Introduction to Machining and Casting

Machining involves removing material from a workpiece using tools like lathes, mills, or drills to achieve precise dimensions and surface finishes. Casting is a manufacturing process where molten metal or plastic is poured into a mold, solidifying into a desired shape with complex geometries. Both processes serve distinct purposes in production, with machining excelling in accuracy and casting enabling the creation of intricate designs.

Overview of Machining Processes

Machining processes involve the controlled removal of material from a workpiece using tools like lathes, mills, and drills to achieve precise dimensions and surface finishes. Common machining techniques include turning, milling, drilling, and grinding, each suited for different shapes and complexities. These processes offer high accuracy and surface quality, making them essential for producing complex metal parts in aerospace, automotive, and medical industries.

Overview of Casting Processes

Casting processes involve pouring molten metal into molds to shape complex parts with intricate geometries and varying sizes. Common casting methods include sand casting, die casting, investment casting, and centrifugal casting, each offering unique advantages in terms of precision, surface finish, and production volume. This process is ideal for manufacturing large, complex metal components with reduced material waste and lower costs compared to machining from solid blocks.

Material Suitability: Machining vs Casting

Machining excels with materials like aluminum, steel, and titanium that require high precision and tight tolerances, enabling complex geometries and smooth finishes. Casting is ideal for metals such as cast iron, aluminum alloys, and bronze, especially when producing large or intricate shapes with lower dimensional accuracy. Material selection between machining and casting depends on factors such as mechanical properties, thermal conductivity, and the required surface quality of the final product.

Dimensional Accuracy and Tolerances

Machining offers superior dimensional accuracy and tighter tolerances compared to casting, often achieving tolerances within +-0.01 mm, making it ideal for precision components. Casting typically results in rougher surfaces and broader tolerances around +-0.1 mm due to shrinkage and cooling irregularities. The choice between machining and casting significantly impacts component fit, function, and the need for subsequent finishing processes.

Cost Comparison: Machining vs Casting

Machining generally incurs higher costs due to labor-intensive processes and material waste, especially for complex geometries or low production volumes. Casting offers cost advantages for large production runs by minimizing material waste and reducing the need for extensive post-processing. Tooling expenses for casting can be significant upfront, but per-unit costs decrease substantially with scale, making casting more economical for high-volume manufacturing compared to machining.

Production Speed and Volume

Machining offers high precision with slower production speed, making it ideal for low to medium volume manufacturing runs and prototypes. Casting enables faster production of large volumes by shaping molten metal into complex forms but typically requires longer setup times for molds. High-volume production favors casting for its efficiency and cost-effectiveness, while machining excels in custom, detailed parts where speed is less critical.

Surface Finish and Quality Considerations

Machining typically provides superior surface finish and tighter dimensional tolerances compared to casting, making it ideal for applications requiring precision and smooth surfaces. Casting often results in a rougher surface due to the mold textures and may require post-processing to achieve similar finish quality. Surface finish in machining can reach as low as 0.2 um Ra, while casting commonly ranges between 3 to 10 um Ra, impacting the overall aesthetic and functional quality of the component.

Typical Applications for Machining and Casting

Machining is commonly used in aerospace, automotive, and medical device manufacturing for producing precise components like turbine blades, engine parts, and surgical instruments with tight tolerances. Casting is ideal for large, complex shapes such as engine blocks, pump housings, and heavy machinery bases found in industries like construction, mining, and energy due to its ability to create near-net-shape parts efficiently. Both methods complement each other, often combining casting for basic forms and machining for finishing and achieving exact specifications.

Choosing Between Machining and Casting

Choosing between machining and casting depends on factors such as production volume, part complexity, and material properties. Machining offers high precision and is ideal for low to medium production runs with tight tolerances, while casting suits complex shapes and high-volume manufacturing but may require secondary machining for finishing. Evaluating cost-effectiveness, lead times, and required mechanical properties helps determine the optimal manufacturing process.

Machining Infographic

libterm.com

libterm.com