Creep is a phenomenon where materials slowly deform under constant stress over time, commonly observed in metals, polymers, and concrete. Understanding creep behavior is crucial for ensuring the longevity and safety of structures and components subjected to high temperatures or continuous loads. Discover how creep impacts your engineering projects and what measures can prevent its damaging effects by reading the full article.

Table of Comparison

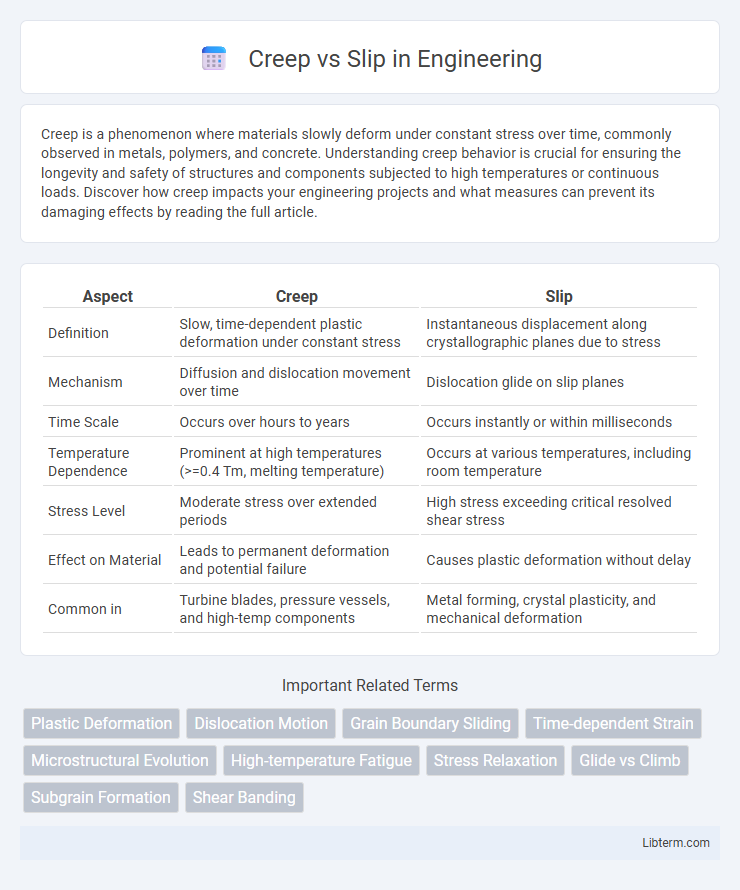

| Aspect | Creep | Slip |

|---|---|---|

| Definition | Slow, time-dependent plastic deformation under constant stress | Instantaneous displacement along crystallographic planes due to stress |

| Mechanism | Diffusion and dislocation movement over time | Dislocation glide on slip planes |

| Time Scale | Occurs over hours to years | Occurs instantly or within milliseconds |

| Temperature Dependence | Prominent at high temperatures (>=0.4 Tm, melting temperature) | Occurs at various temperatures, including room temperature |

| Stress Level | Moderate stress over extended periods | High stress exceeding critical resolved shear stress |

| Effect on Material | Leads to permanent deformation and potential failure | Causes plastic deformation without delay |

| Common in | Turbine blades, pressure vessels, and high-temp components | Metal forming, crystal plasticity, and mechanical deformation |

Understanding the Concepts: Creep and Slip

Creep refers to the slow, continuous deformation of a material under constant stress, often occurring at high temperatures or over extended periods. Slip involves the sudden, localized movement of dislocations within the crystal structure, enabling plastic deformation under applied shear stress. Understanding the differences between creep and slip is essential for predicting material behavior under varying mechanical and thermal conditions.

Fundamental Differences Between Creep and Slip

Creep and slip are distinct deformation mechanisms in materials science, with creep referring to the time-dependent, gradual deformation under constant stress, primarily occurring at high temperatures. Slip involves the immediate displacement of atoms along specific crystallographic planes and directions, resulting in plastic deformation due to applied shear stress. The fundamental difference lies in creep's reliance on diffusion and dislocation movement over time, whereas slip is a rapid, dislocation-driven process activated by sufficient shear stress.

Causes of Creep in Materials

Creep in materials occurs due to prolonged exposure to constant stress at elevated temperatures, causing time-dependent plastic deformation. Atomic diffusion, dislocation movement, and grain boundary sliding contribute to material creep under sustained loads. This behavior is distinct from slip, where immediate dislocation glide causes deformation under applied stress without significant time dependency.

Primary Factors Influencing Slip

Slip is primarily influenced by factors such as surface roughness, lubrication presence, and contact pressure between materials. Material composition and operating temperature significantly affect slip behavior by altering frictional properties and deformation mechanisms. Understanding microstructural characteristics and environmental conditions is essential for predicting and controlling slip in engineering applications.

Effects of Temperature on Creep and Slip

Temperature significantly influences creep and slip behaviors in materials, accelerating atomic diffusion and increasing dislocation mobility. Elevated temperatures cause enhanced creep deformation due to time-dependent plastic strain under constant stress, while slip mechanisms become more pronounced as thermal energy facilitates dislocation glide on specific crystallographic planes. Understanding temperature effects is critical for predicting mechanical performance and failure in high-temperature applications such as turbine blades and nuclear reactors.

Material Behavior Under Creep vs Slip Conditions

Creep describes the time-dependent, permanent deformation of a material under constant stress, typically occurring at high temperatures where atomic diffusion or dislocation motion dominates. Slip involves the displacement along specific crystallographic planes due to shear stress, leading to immediate plastic deformation governed by dislocation glide. Under creep conditions, materials exhibit gradual strain accumulation influenced by diffusion mechanisms, while slip behavior results in rapid deformation controlled by lattice dislocation movement.

Real-World Examples: Creep vs Slip

In bridge construction, creep manifests as the slow, permanent deformation of concrete beams under sustained loads, causing gradual sagging over time, while slip is observed in steel girders where connections or joints momentarily shift under dynamic loads, leading to sudden displacements. Railway tracks experience creep as rails slowly elongate due to constant train pressure and temperature fluctuations, contrasting with slip events during wheel skidding that cause abrupt rail shifts and wear. In geotechnical engineering, soil creep refers to the slow downhill movement of soil on slopes over months or years, whereas slip occurs as rapid landslides triggered by heavy rainfall or seismic activity.

Methods to Measure and Analyze Creep and Slip

Methods to measure creep and slip include strain gauge monitoring and digital image correlation, which provide precise deformation data over time under specific loads. Creep is analyzed using time-dependent stress-strain curves derived from constant load tests, while slip is quantified through displacement sensors and shear strain measurements in lubrication or material interfaces. Advanced techniques such as atomic force microscopy and nanoindentation enable nanoscale analysis of creep and slip behavior in materials science.

Prevention and Control Strategies

Effective prevention and control of creep and slip in materials engineering involve maintaining operational temperatures below critical thresholds and employing surface treatments to reduce friction and wear. Utilizing alloying elements that enhance grain boundary strength prevents creep deformation, while proper lubrication and surface coatings minimize slip-induced failures. Implementing real-time monitoring systems for stress and temperature variations aids in early detection, enabling timely maintenance and prolonging component lifespan.

Industry Applications and Implications

Creep and slip phenomena critically affect the performance and longevity of materials in industrial applications such as aerospace, automotive, and construction. Creep involves time-dependent deformation under constant stress, impacting turbine blades and structural components exposed to high temperatures, while slip refers to sudden displacement along a fault line or grain boundary, influencing metal forming and failure in manufacturing processes. Understanding these mechanisms enables engineers to select appropriate materials and design parameters to mitigate failure risks and enhance safety and reliability in industrial systems.

Creep Infographic

libterm.com

libterm.com