Annealing is a heat treatment process used to alter the physical and sometimes chemical properties of a material, typically metal or glass, to increase its ductility and reduce hardness. It involves heating the material to a specific temperature and then allowing it to cool slowly, which helps relieve internal stresses and improve its machinability. Explore the rest of this article to learn how annealing can enhance your manufacturing processes or material performance.

Table of Comparison

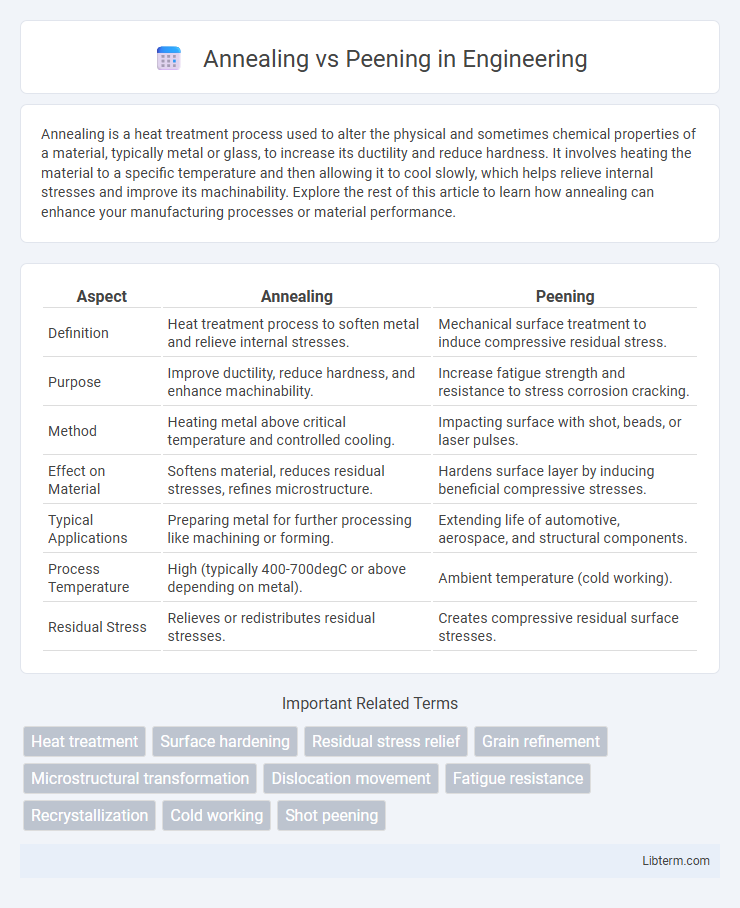

| Aspect | Annealing | Peening |

|---|---|---|

| Definition | Heat treatment process to soften metal and relieve internal stresses. | Mechanical surface treatment to induce compressive residual stress. |

| Purpose | Improve ductility, reduce hardness, and enhance machinability. | Increase fatigue strength and resistance to stress corrosion cracking. |

| Method | Heating metal above critical temperature and controlled cooling. | Impacting surface with shot, beads, or laser pulses. |

| Effect on Material | Softens material, reduces residual stresses, refines microstructure. | Hardens surface layer by inducing beneficial compressive stresses. |

| Typical Applications | Preparing metal for further processing like machining or forming. | Extending life of automotive, aerospace, and structural components. |

| Process Temperature | High (typically 400-700degC or above depending on metal). | Ambient temperature (cold working). |

| Residual Stress | Relieves or redistributes residual stresses. | Creates compressive residual surface stresses. |

Introduction to Annealing and Peening

Annealing is a heat treatment process that involves heating metal to a specific temperature and then cooling it slowly to remove internal stresses and enhance ductility. Peening, on the other hand, is a mechanical process that strengthens metals by inducing compressive surface stresses through repeated impacts, such as shot peening or laser peening. Both techniques improve metal properties but target different aspects: annealing modifies the microstructure to reduce brittleness, while peening increases fatigue resistance by hardening the surface.

Understanding the Annealing Process

Annealing is a heat treatment process that involves heating a metal to a specific temperature and then slowly cooling it to remove internal stresses and improve its ductility. This process restructures the metal's microstructure, resulting in enhanced machinability and reduced hardness, which contrasts with peening, a surface treatment used to increase fatigue strength by inducing compressive stresses. Understanding annealing is essential for optimizing metal properties during manufacturing and repair operations.

How Peening Works: An Overview

Peening works by bombarding the metal surface with small, hard particles such as steel shots or beads, inducing compressive residual stress that enhances fatigue resistance and strength. This plastic deformation process refines grain structure and closes surface cracks, improving the metal's mechanical properties without altering its bulk composition. Unlike annealing, which softens metals through controlled heating, peening mechanically strengthens surfaces, making it essential for improving durability in components like automotive parts and aerospace structures.

Key Differences between Annealing and Peening

Annealing is a heat treatment process that softens metal by heating it to a specific temperature and then cooling it slowly to relieve internal stresses and improve ductility. Peening, on the other hand, is a mechanical surface treatment that induces compressive stresses by bombarding the metal surface with small spherical media to enhance fatigue strength and resistance to stress-corrosion cracking. The key differences lie in their methods--thermal for annealing versus mechanical for peening--and their primary purposes, with annealing aimed at softening and stress relief, while peening focuses on surface hardening and fatigue life improvement.

Applications of Annealing in Industry

Annealing is widely used in the metalworking industry to improve ductility and reduce hardness in steel, copper, and aluminum alloys, facilitating easier machining and forming processes. It is essential in the manufacturing of automotive components, aerospace parts, and electrical conductors where controlled mechanical properties and stress relief are critical. Unlike peening, which enhances surface hardness and fatigue resistance by shock waves, annealing modifies the entire microstructure, making it indispensable for redesigning metal properties during production.

Practical Uses of Peening Techniques

Peening techniques such as shot peening and laser peening are widely used to enhance the fatigue strength and stress resistance of metal components in aerospace, automotive, and marine industries. These methods induce beneficial compressive residual stresses on the surface, preventing crack initiation and extending the lifespan of parts like turbine blades, gear shafts, and structural components. Unlike annealing, which primarily softens metals to relieve internal stresses, peening improves mechanical durability without compromising hardness.

Benefits of Annealing for Material Properties

Annealing enhances material properties by reducing internal stresses, improving ductility, and refining grain structure, which results in increased toughness and machinability. This heat treatment process restores the metal's original softness after work hardening, allowing for easier forming and shaping. Unlike peening, annealing provides uniform thermal treatment that improves homogeneity and structural stability in metals like steel and aluminum alloys.

Advantages of Peening for Metal Strength

Peening significantly improves metal strength by inducing compressive residual stresses on the surface, which enhances fatigue resistance and reduces the risk of crack initiation. Unlike annealing, which softens metals by heating and slow cooling, peening maintains or increases hardness while improving durability. This process is especially beneficial for components subjected to cyclic loads, extending their service life effectively.

Choosing Between Annealing and Peening

Choosing between annealing and peening depends on the desired mechanical properties and application requirements of the metal. Annealing softens the material, improves ductility, and relieves internal stresses by heating and controlled cooling, making it ideal for machining and forming processes. Peening enhances fatigue strength and surface hardness by inducing compressive residual stresses through mechanical impact, making it suitable for components exposed to cyclic loading.

Conclusion: Selecting the Right Process

Selecting the right process between annealing and peening depends on the desired material properties and application requirements. Annealing effectively softens metals, enhances ductility, and reduces internal stresses, making it ideal for subsequent shaping or machining. Peening, on the other hand, improves surface strength and fatigue resistance by inducing compressive residual stresses, best suited for enhancing durability in structural components.

Annealing Infographic

libterm.com

libterm.com