An absolute encoder provides precise position feedback by generating a unique code for each shaft position, eliminating the need for reference resets. This technology ensures accurate and reliable data in applications ranging from robotics to industrial automation. Discover how an absolute encoder can enhance your system's performance by exploring the rest of the article.

Table of Comparison

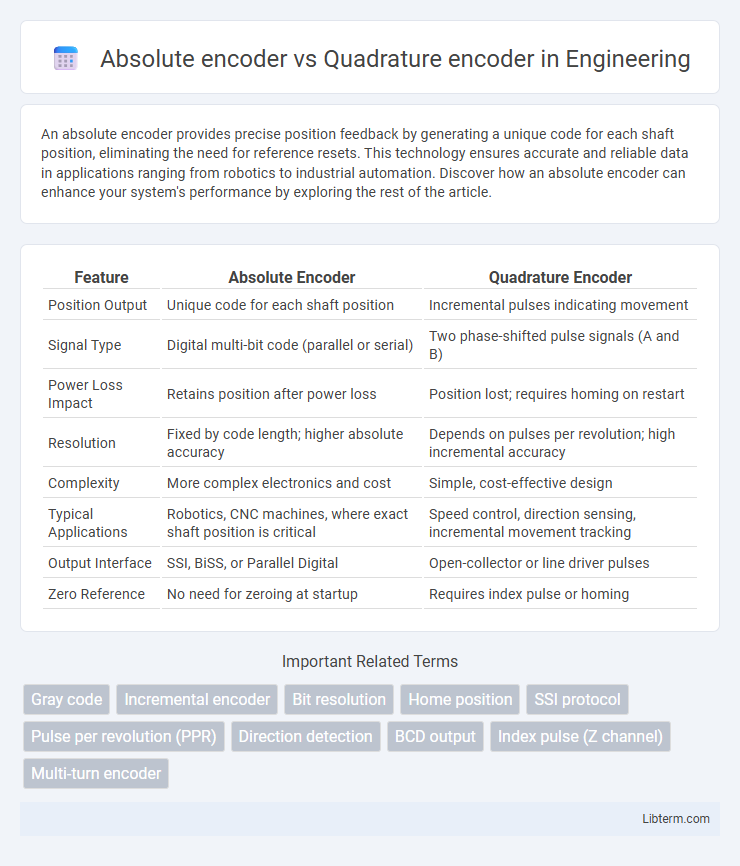

| Feature | Absolute Encoder | Quadrature Encoder |

|---|---|---|

| Position Output | Unique code for each shaft position | Incremental pulses indicating movement |

| Signal Type | Digital multi-bit code (parallel or serial) | Two phase-shifted pulse signals (A and B) |

| Power Loss Impact | Retains position after power loss | Position lost; requires homing on restart |

| Resolution | Fixed by code length; higher absolute accuracy | Depends on pulses per revolution; high incremental accuracy |

| Complexity | More complex electronics and cost | Simple, cost-effective design |

| Typical Applications | Robotics, CNC machines, where exact shaft position is critical | Speed control, direction sensing, incremental movement tracking |

| Output Interface | SSI, BiSS, or Parallel Digital | Open-collector or line driver pulses |

| Zero Reference | No need for zeroing at startup | Requires index pulse or homing |

Understanding Absolute Encoders

Absolute encoders provide unique position values at every point of rotation by using a multi-bit digital output, enabling precise and real-time position monitoring without requiring a reference point. In contrast, quadrature encoders generate incremental pulses that only indicate relative position changes, necessitating a homing sequence to establish an initial reference. Understanding absolute encoders is crucial for applications demanding high reliability and absolute position feedback, such as robotics, industrial automation, and CNC machinery.

Introduction to Quadrature Encoders

Quadrature encoders provide two output signals, A and B, which are 90 degrees out of phase to determine direction and speed of rotation. Unlike absolute encoders that deliver unique position values, quadrature encoders rely on counting pulses to track relative position. Their high resolution and simplicity make them ideal for motion control applications requiring precise incremental feedback.

Working Principle: Absolute vs Quadrature Encoders

Absolute encoders generate a unique code for each shaft position, providing precise angular information with no loss during power interruptions, using a multi-track disk and optical or magnetic sensors to identify exact positions. Quadrature encoders produce two square wave outputs shifted by 90 degrees, enabling direction detection and relative position tracking through pulse counting, but require a reference point after power loss. The fundamental difference lies in absolute encoders delivering position as a digital code directly correlating to the angle, while quadrature encoders output incremental signals interpreted by an external controller for movement tracking.

Key Differences Between Absolute and Quadrature Encoders

Absolute encoders provide unique position values for each shaft angle, offering precise, non-ambiguous position data even after power loss. Quadrature encoders generate two out-of-phase signals to track position changes and direction, requiring an external counter to maintain absolute position information. The key difference lies in absolute encoders' direct measurement of position, while quadrature encoders rely on incremental counts and require initialization to establish a reference point.

Advantages of Absolute Encoders

Absolute encoders provide unique position values for every shaft angle, enabling precise and reliable position tracking even after power loss, unlike quadrature encoders that rely on incremental counts. They eliminate the need for homing procedures during startup, significantly reducing downtime and improving system efficiency. The inherent ability to retain absolute position data makes absolute encoders ideal for applications requiring high accuracy, safety, and repeatability in automation and robotics.

Benefits of Quadrature Encoders

Quadrature encoders offer precise position and speed feedback by providing two output signals 90 degrees out of phase, enabling direction detection and improved resolution. Their incremental nature makes them cost-effective and suitable for high-speed applications, offering real-time position tracking without complex calibration. These encoders also simplify integration with motion control systems, delivering reliable and continuous feedback essential for robotics, CNC machines, and automation processes.

Typical Applications of Absolute Encoders

Absolute encoders are commonly used in robotics, industrial automation, and CNC machinery where precise position feedback is critical for accurate control. They provide unique position values for each shaft angle, making them ideal for applications requiring exact start-up positioning and error-free tracking after power loss. Typical devices benefiting from absolute encoders include robotic arms, elevator systems, and servo motors in manufacturing lines.

Common Uses for Quadrature Encoders

Quadrature encoders are commonly used in motion control systems, robotics, and industrial automation due to their ability to provide precise position and speed feedback through two output signals in quadrature. These encoders are ideal for applications requiring accurate direction and incremental position measurements, such as conveyor systems, motor shaft positioning, and CNC machinery. The incremental nature of quadrature encoders makes them cost-effective and suitable for dynamic control tasks where high resolution and reliable signal detection are critical.

Choosing the Right Encoder for Your Project

Absolute encoders provide unique position values for each shaft angle, ensuring precise feedback after power loss, ideal for applications requiring accurate position retention. Quadrature encoders generate pulses indicating movement direction and speed, making them suitable for high-speed monitoring but risk losing position without a reference point. Selecting the right encoder depends on the project's need for position accuracy, power interruption tolerance, and budget constraints.

Absolute Encoder vs Quadrature Encoder: Summary Comparison

Absolute encoders provide unique position values for each shaft location, ensuring precise, unambiguous position tracking even after power loss, unlike quadrature encoders, which generate relative position signals requiring a reference point and can lose position during power interruptions. Quadrature encoders use two output channels in phase quadrature to detect direction and speed through pulse counting, offering cost-effective solutions for applications where incremental position feedback suffices. The choice between absolute and quadrature encoders depends on the need for true position retention versus simpler incremental position tracking, with absolute encoders favored in critical applications demanding position accuracy and reliability.

Absolute encoder Infographic

libterm.com

libterm.com